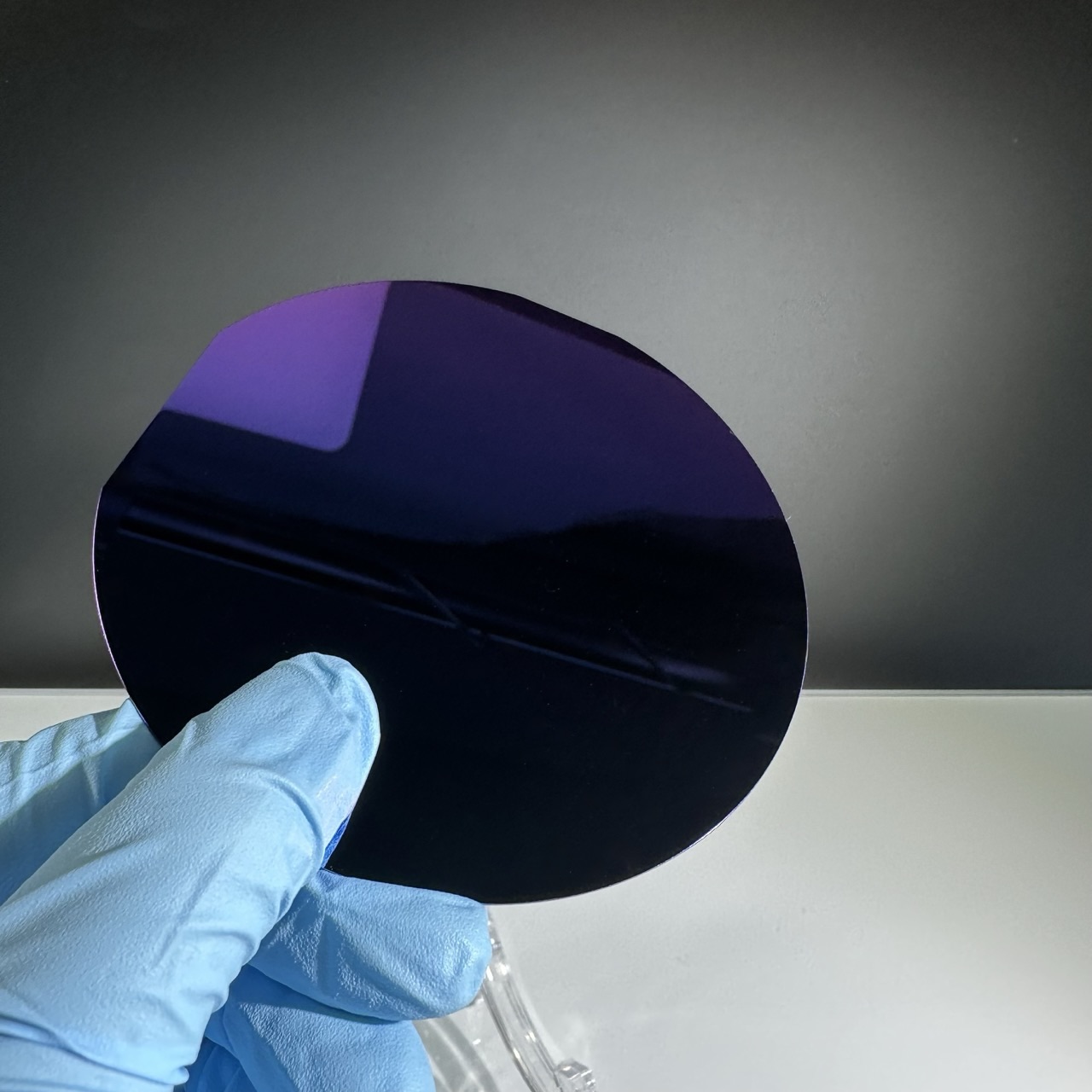

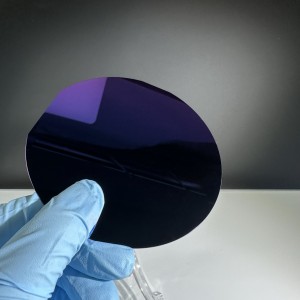

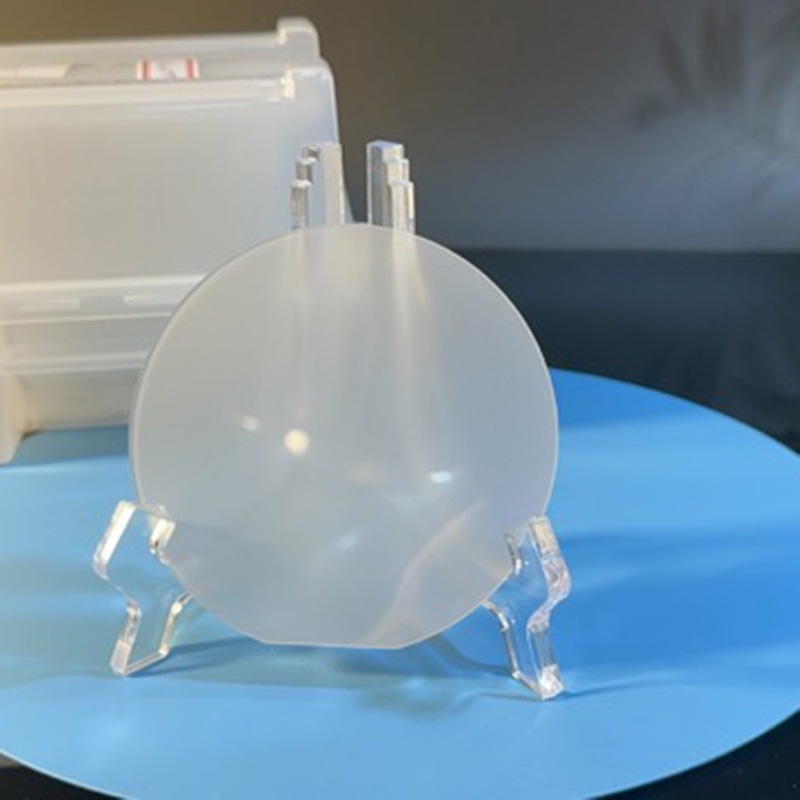

Silicon Dioxide wafer SiO2 wafer siri ike ekpochapụrụ, Prime na ọkwa ule

Ewebata igbe wafer

| Ngwaahịa | Thermal oxide (Si + SiO2) wafers |

| Usoro mmepụta | LPCVD |

| Nchacha elu | SSP/DSP |

| Dayameta | 2inch / 3inch / 4inch / 5inch/ 6inch |

| Ụdị | Ụdị P ụdị / N |

| Ọkpụrụkpụ Oxidation Layer | 100nm ~ 1000nm |

| Nhazi | <100> <111> |

| Eletriki resistivity | 0.001-25000 (Ω•cm) |

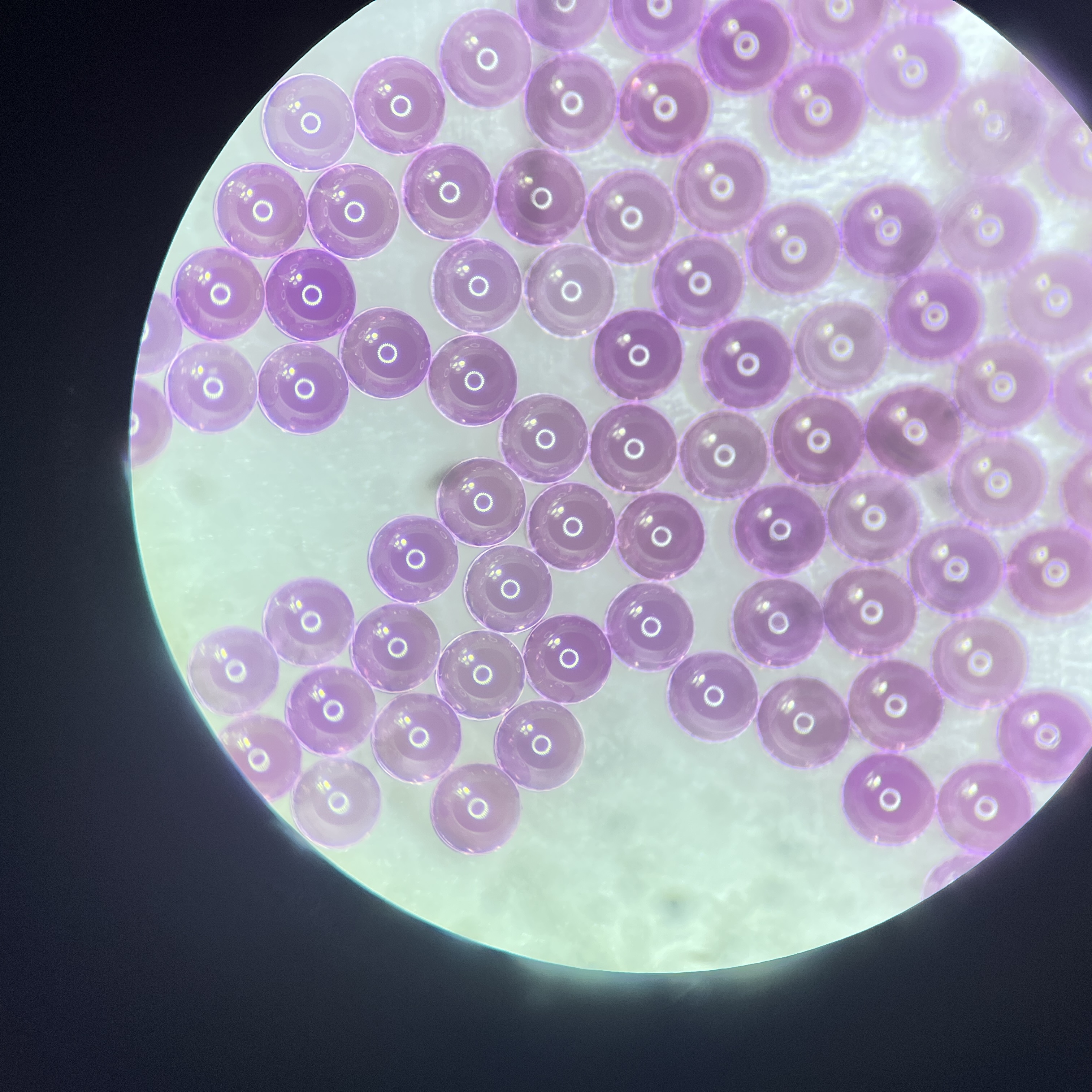

| Ngwa | A na-eji ya maka ihe na-ebu ihe nlele radieshon synchrotron, mkpuchi PVD/CVD dị ka mkpụrụ, magnetron sputtering uto sample, XRD, SEM,Atomic Force, infrared spectroscopy, fluorescence spectroscopy na ihe nyocha nyocha ndị ọzọ, mkpụrụ ndụ mkpụrụ ndụ epitaxial molecular beam, nyocha X-ray nke kristal semiconductor. |

Silicon oxide wafers bụ ihe nkiri sịlịkọn dioxide toro n'elu silicon wafers site na ikuku oxygen ma ọ bụ uzuoku mmiri na oke okpomọkụ (800°C ~ 1150°C) na-eji usoro oxidation thermal na akụrụngwa ikuku ikuku ikuku.The ọkpụrụkpụ nke usoro sitere na 50 nanometers na 2 microns, usoro okpomọkụ ruo 1100 degrees Celsius, na-eto eto na-ekewa n'ime "mmiri oxygen" na "akọrọ oxygen" abụọ ụdị.Thermal Oxide bụ oyi akwa oxide nke “toro”, nke nwere ịdị n'otu dị elu, densification dị mma na ike dielectric dị elu karịa ọkwa oxide nke CVD etinyere, na-ebute ogo dị elu.

Oxygen Oxidation kpọrọ nkụ

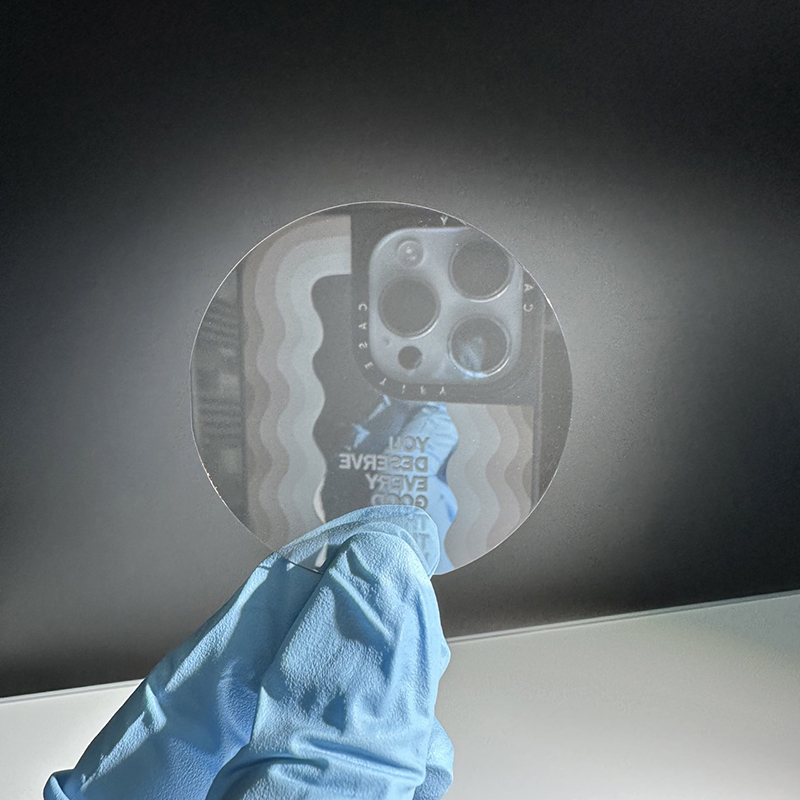

Silicon na-emeghachi omume na ikuku oxygen na oyi akwa oxide na-aga n'ihu na oyi akwa.Ekwesịrị ịme ikuku oxidation akọrọ na okpomọkụ site na 850 ruo 1200 Celsius, yana ọnụego uto dị ala, enwere ike iji ya mee ihe maka uto ọnụ ụzọ MOS.A na-ahọrọ oxidation kpọrọ nkụ karịa oxidation mmiri mgbe achọrọ akwa silicon oxide dị elu nke dị oke mkpa.Ike oxidation akọrọ: 15nm ~ 300nm.

2. Mmiri Oxidation

Usoro a na-eji vepo mmiri na-emepụta oyi akwa oxide site na ịbanye n'ime ọkụ ọkụ n'okpuru ọnọdụ okpomọkụ dị elu.The densification nke mmiri oxygen oxidation bụ ubé njọ karịa akọrọ oxygen oxidation, ma e jiri ya tụnyere akọrọ oxygen oxidation uru ya bụ na ọ nwere elu ibu ọnụego, adabara ihe karịrị 500nm film ibu.Ike oxidation mmiri: 500nm ~ 2µm.

Igwe ọkụ ikuku ikuku nke AEMD bụ ọkpọkọ ọkụ ọkụ Czech kwụ ọtọ, nke ejiri usoro nkwụsi ike dị elu, ịdị n'otu ihe nkiri dị mma na njikwa ihe dị elu.Igwe ọkụ silicon oxide tube nwere ike hazie ihe ruru 50 wafers kwa tube, yana ọmarịcha intra- na inter-wafers edo edo.

Eserese zuru ezu