12inch zuru oke akpaaka nkenke dicing hụrụ akụrụngwa Wafer raara onwe ya nye maka Si/SiC & HBM (Al)

Usoro nka

| Oke | Nkọwapụta |

| Ogo ọrụ | Φ8", Φ12" |

| Spindle | Abụọ-axis 1.2/1.8/2.4/3.0, Max 60000 rpm |

| Nha agụba | 2" ~ 3" |

| Y1/Y2 Axis

| Mmụba otu nzọụkwụ: 0.0001 mm |

| Izi ezi n'ọkwa: <0.002 mm | |

| Oke ịkpụ: 310 mm | |

| Axis X | Oke ọsọ nri: 0.1-600 mm/s |

| Z1 / Z2 Axis

| Mmụba otu nzọụkwụ: 0.0001 mm |

| Ndokwa ziri ezi: ≤ 0.001 mm | |

| θ Axis | Ndokwa ziri ezi: ± 15" |

| Ebe nhicha

| Ọsọ ntụgharị: 100-3000 rpm |

| Usoro nhicha: sachaa akpaaka & kpochaa | |

| Voltaji na-arụ ọrụ | 3-adọ 380V 50Hz |

| Akụkụ (W×D×H) | 1550×1255×1880 mm |

| Ibu | 2100 n'arọ |

Ụkpụrụ ọrụ

Akụrụngwa na-enweta mbelata nkenke dị elu site na teknụzụ ndị a:

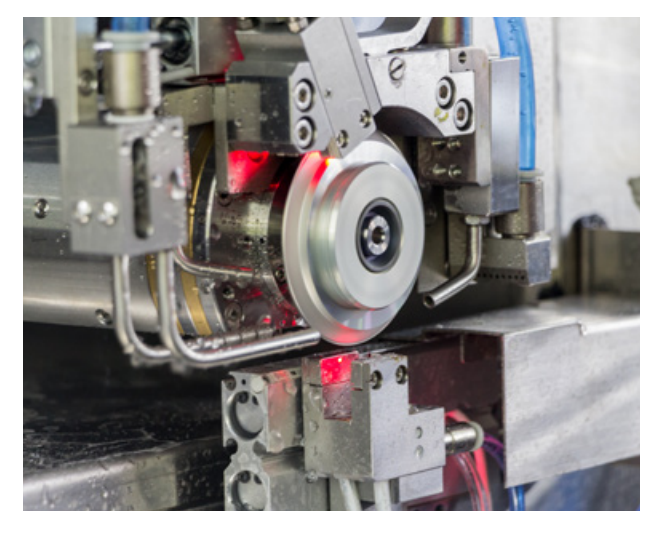

1.High-Rigidity Spindle System: Ntugharị na-agba ọsọ ruo 60,000 RPM, nke a na-eji akwa diamond ma ọ bụ isi ịkpụ laser iji mee mgbanwe na ihe onwunwe dị iche iche.

2.Multi-Axis Motion Control: X / Y / Z-axis nhazi ziri ezi nke ± 1μm, jikọtara ya na ọnụ ọgụgụ dị elu nke grating dị elu iji hụ na ụzọ nkwụsị na-enweghị isi.

3.Intelligent Visual Alignment: CCD dị elu (5 megapixels) na-achọpụta na-egbutu okporo ụzọ ma na-akwụ ụgwọ maka mgbagha ihe ma ọ bụ nkwụsịtụ.

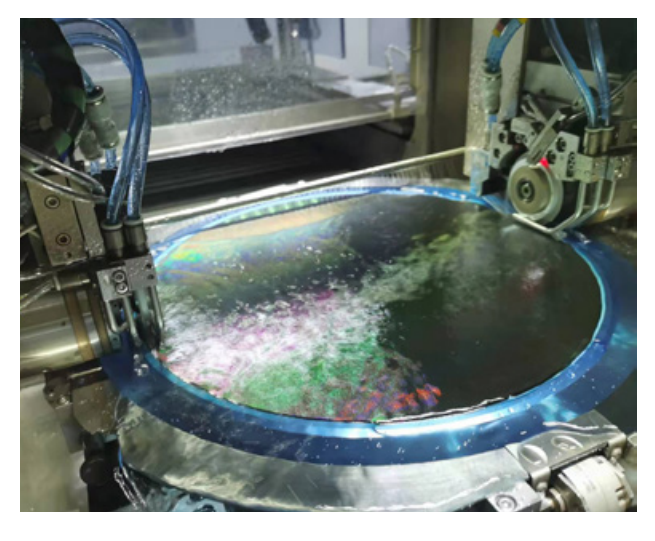

4.Cooling & Dust Removal: Integrated dị ọcha mmiri jụrụ usoro na agụụ mmịpụta uzuzu na-ebelata mmetụta okpomọkụ na urughuru ofufe.

Ụdị ịkpụcha

1.Blade Dicing: Kwesịrị ekwesị maka ihe semiconductor omenala dị ka Si na GaAs, na obosara kerf nke 50-100μm.

2.Stealth Laser Dicing: Ejiri ya maka wafers ultra-thin (<100μm) ma ọ bụ ihe ndị na-emebi emebi (dịka, LT / LN), na-eme ka nkewa na-enweghị nchekasị.

Ngwa a na-ahụkarị

| Ngwa dakọtara | Ubi ngwa | Ihe nhazi chọrọ |

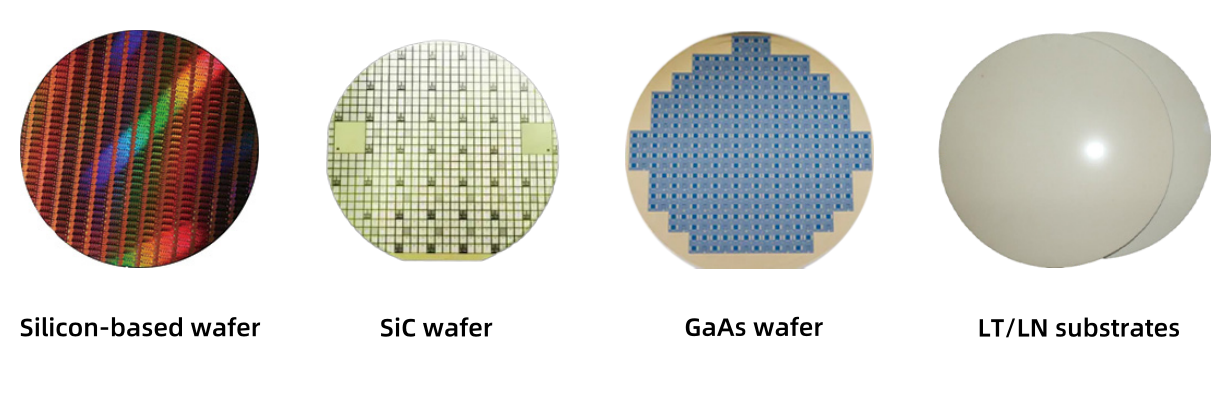

| Silikon (Si) | ICs, ihe mmetụta MEMS | Mbelata nkenke dị elu, mgbapu <10μm |

| Silicon Carbide (SiC) | Ngwaọrụ ike (MOSFET/diodes) | Mbelata mmebi dị ala, njikwa njikwa okpomọkụ |

| Gallium Arsenide (GaAs) | Ngwa RF, ibe optoelectronic | Mgbochi micro-crack, njikwa ịdị ọcha |

| Ngwa LT/LN | Ihe nzacha SAW, ndị modulators anya | Mbelata na-enweghị nchekasị, na-echekwa akụrụngwa piezoelectric |

| Ngwa seramiiki | Modul ike, nkwakọ ngwaahịa LED | Nhazi ihe siri ike dị elu, ọnụ ọnụ |

| Frames QFN/DFN | Nkwakọ ngwaahịa dị elu | Multi-mgbawa n'out oge ọnwụ, arụmọrụ njikarịcha |

| WLCSP Wafers | Nkwakọ ngwaahịa ọkwa wafer | Ngwunye wafers dị obere (50μm) na-enweghị mmebi. |

Uru

1. Igwe onyonyo cassette dị elu na-enyocha ihe mgbochi mgbochi, ntinye ngwa ngwa mbufe, yana ike mmezi njehie siri ike.

2. Kachasị mma abụọ-spindle ịkpụ mode, na-eme ka arụmọrụ dị ka 80% tụnyere otu-spindle usoro.

3. Kpọrọ bọọlụ na-ebubata nkenke, ntuziaka linear, na Y-axis grating scale mechiri emechi, na-eme ka nkwụsi ike ogologo oge nke nrụpụta dị elu.

4. Nbudata / nbudata na-akpaghị aka zuru oke, ntinye mbufe, ịkpụ nhazi, na nyocha kerf, na-ebelata ọrụ ọrụ (OP).

5.Gantry-style spindle arịọnụ Ọdịdị, na a kacha nta dual-agụba spacing nke 24mm, na-enyere sara mbara adaptability maka dual-spindle ọnwụ Filiks.

Atụmatụ

1.High-nkenke na-abụghị kọntaktị elu nha.

2.Multi-wafer dual-blade ọnwụ na otu tray.

3.Automatic calibration, kerf inspection, and blade breakage detection systems.

4.Supports iche iche usoro na selectable akpaka alignment algọridim.

5.Fault onwe-mmezi arụmọrụ na ezigbo oge multi-ọnọdụ nlekota oru.

6.First-cut nnyocha ike post-mmalite dicing.

7.Customizable factory akpaaka modul na ndị ọzọ nhọrọ ọrụ.

Ngwa akụrụngwa

Anyị na-enye nkwado zuru oke site na nhọrọ akụrụngwa ruo nrụzi ogologo oge:

(1) Mmepe ahaziri ahazi

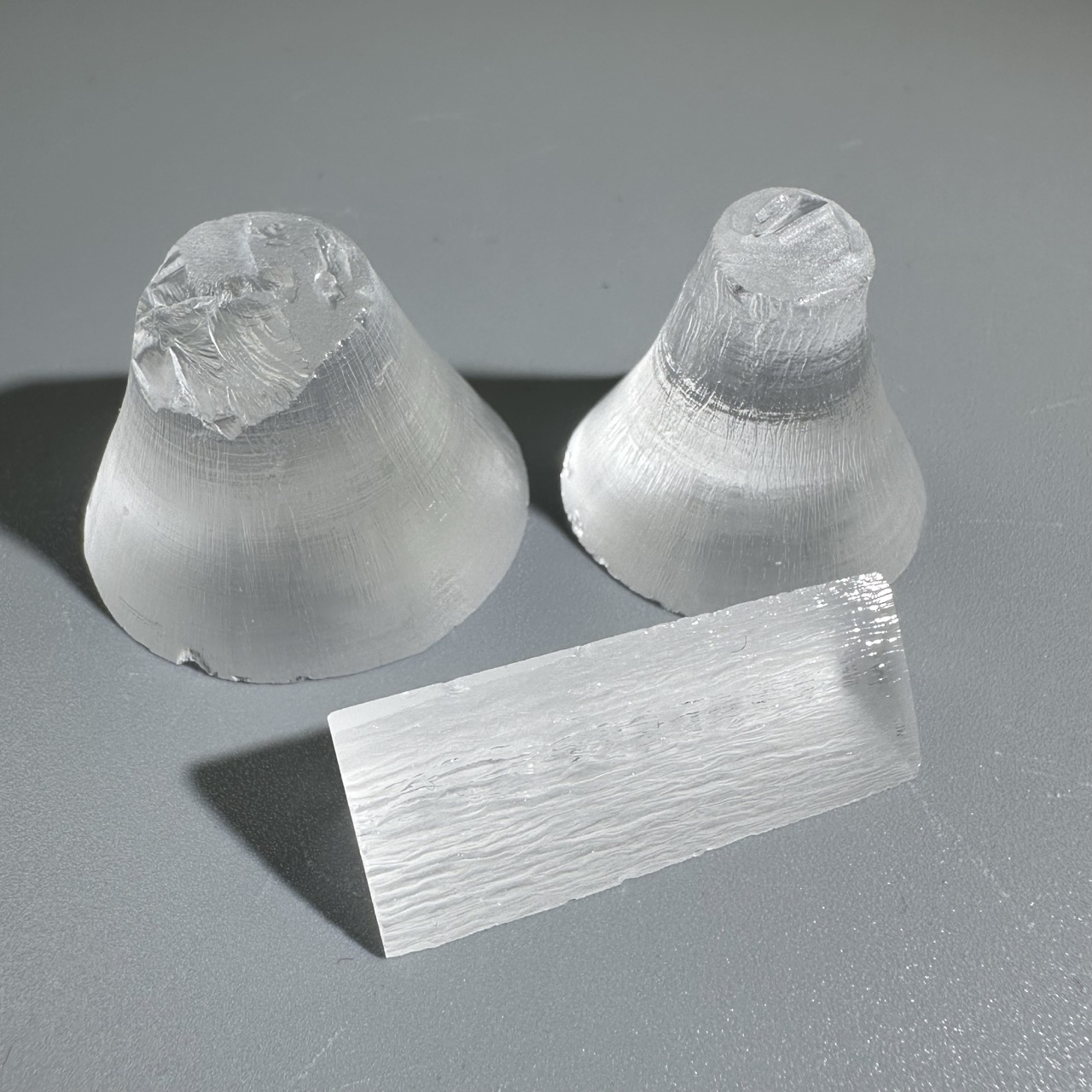

Na-atụ aro ka agụba/Laser ngwọta dabere na ihe onwunwe (dịka, SiC hardness, GaAs brittleness).

· Na-enye nnwale nlele n'efu iji nyochaa ịdị mma ịkpụ (gụnyere chipping, obosara kerf, adịghị ike elu, wdg).

(2) Ọzụzụ nka nka

Ọzụzụ ndị bụ isi: Arụ ọrụ akụrụngwa, ngbanwe oke, mmezi oge niile.

Usoro mmụta dị elu: njikarịcha usoro maka ihe ndị dị mgbagwoju anya (dịka ọmụmaatụ, ịkpụ mkpụrụ LT na-enweghị nchekasị).

(3) Nkwado mgbe-ire ahịa

· 24/7 Azịza: Nchọpụta nyocha dịpụrụ adịpụ ma ọ bụ enyemaka saịtị.

Nnweta akụkụ mapụtara: spindles, agụba, na ngwa anya maka nnọchi ngwa ngwa.

· Nlekọta mgbochi: Nhazi oge niile iji kwado izi ezi na ịgbatị ndụ ọrụ.

Uru Anyị

Ahụmahụ ụlọ ọrụ: Na-eje ozi 300+ semiconductor zuru ụwa ọnụ na ndị na-emepụta elektrọnik.

✔ Technology Cutting-Edge: Ntuziaka ziri ezi na usoro servo na-eme ka nkwụsi ike nke ụlọ ọrụ na-eduga.

✔ Global Service Network: Mkpuchi na Asia, Europe, na North America maka nkwado mpaghara.

Maka ule ma ọ bụ ajụjụ, kpọtụrụ anyị!