Igwe na-ekpuchi ion Beam maka sapphire SiC Si

Eserese zuru ezu

Nleba anya ngwaahịa nke igwe ion Beam Polishing Machine

Igwe ion Beam Figuring na Polishing Machine dabere na ụkpụrụ nke ion sputtering. N'ime ụlọ nwere oghere dị elu, isi iyi ion na-emepụta plasma, nke na-eme ka ọ bụrụ ọkụ ion dị elu. Oghere a na-atụ bọmbụ n'elu akụkụ ngwa anya, na-ewepụ ihe dị na ọnụ ọgụgụ atomiki iji nweta nzizi na imecha elu nke ọma.

Dị ka usoro na-abụghị kọntaktị, ion beam polishing na-ewepụ nchekasị n'ibu ma na-ezere mmebi dị n'okpuru ala, na-eme ka ọ dị mma maka ịmepụta optics dị elu nke a na-eji na mbara igwe, ikuku ikuku, semiconductor, na ngwa nyocha dị elu.

Ụkpụrụ na-arụ ọrụ nke ion Beam Polishing Machine

Ọgbọ ion

A na-ewebata gas na-adịghị arụ ọrụ (dịka ọmụmaatụ, argon) n'ime oghere oghere wee tinye ion site na mwepu eletrik ka ọ bụrụ plasma.

Ọsọ ọsọ & Nhazi Ntugharị

A na-emeziwanye ion ahụ ruo ọtụtụ narị ma ọ bụ puku eletrọn volts (eV) ma mee ka ọ bụrụ ebe kwụsiri ike, ebe ọkụ gbadoro anya.

Mwepụ ihe

Oghere ion ahụ na-efesa atom site n'elu na-enweghị mmalite mmeghachi omume kemịkal.

Nchọpụta mperi & atụmatụ ụzọ

A na-eji interferometry tụọ ndịiche dị n'elu. A na-etinye ọrụ mwepu iji chọpụta oge ibi na iwepụta ụzọ ngwaọrụ kachasị mma.

Ndozi aka mechiri emechi

Usoro nhazigharị nke nhazi na nha na-aga n'ihu ruo mgbe emezuru ebumnuche RMS/PV.

Akụkụ ndị dị mkpa nke igwe ion Beam Polishing Machine

Ndakọrịta n'elu ụwa- Na-ahazi mbara ala dị larịị, okirikiri, aspherical na n'ụdị efu

Ọnụego mwepu-Stable- Na-enyere aka mmezi ọnụọgụ sub-nanometer

Nhazi mmebi na-adịghị- Enweghị ntụpọ n'okpuru ala ma ọ bụ mgbanwe nhazi

Arụmarụ na-agbanwe agbanwe- Na-arụ ọrụ nke ọma na ihe ndị siri ike dị iche iche

Ndozi ugboro ole dị ala/ọkara- Na-ewepụ njehie na-enweghị imepụta ihe dị n'etiti / elu ugboro ugboro

Achọrọ nlekọta dị ala- Ogologo oge na-aga n'ihu na-arụ ọrụ na obere oge nkwụsị

Nkọwapụta nka na ụzụ isi nke igwe ion Beam Polishing

| Ihe | Nkọwapụta |

| Usoro nhazi | Ion sputtering na nnukwu agụụ na gburugburu ebe obibi |

| Ụdị nhazi | Ntugharị elu na-enweghị kọntaktị & polishing |

| Oke workpiece size | Φ4000 mm |

| Motion Axes | 3-axis / 5-axis |

| Mwepụ kwụsie ike | ≥95% |

| Izi ezi n'elu | PV <10 nm; RMS ≤ 0.5 nm (nke RMS <1 nm; PV <15 nm) |

| Ike mmezi ugboro ugboro | Na-ewepu mpe mpe mpe mpe mpe mpe mperi na-ewebata mperi etiti/oke ugboro |

| Ọrụ na-aga n'ihu | 3-5 izu na-enweghị agụụ mmezi |

| Ọnụ nlekọta | Dị ala |

Ikike nhazi nke igwe na-ekpo ọkụ ion Beam

Ụdị elu akwadoro

Dị Mfe: Flat, Spherical, Prism

Mgbagwoju anya: Symmetric/asymmetric asphere, off-axis asphere, cylindrical

Pụrụ iche: Ultra-thin optics, slat optics, hemispherical optics, conformal optics, phase plates, freeform surfaces.

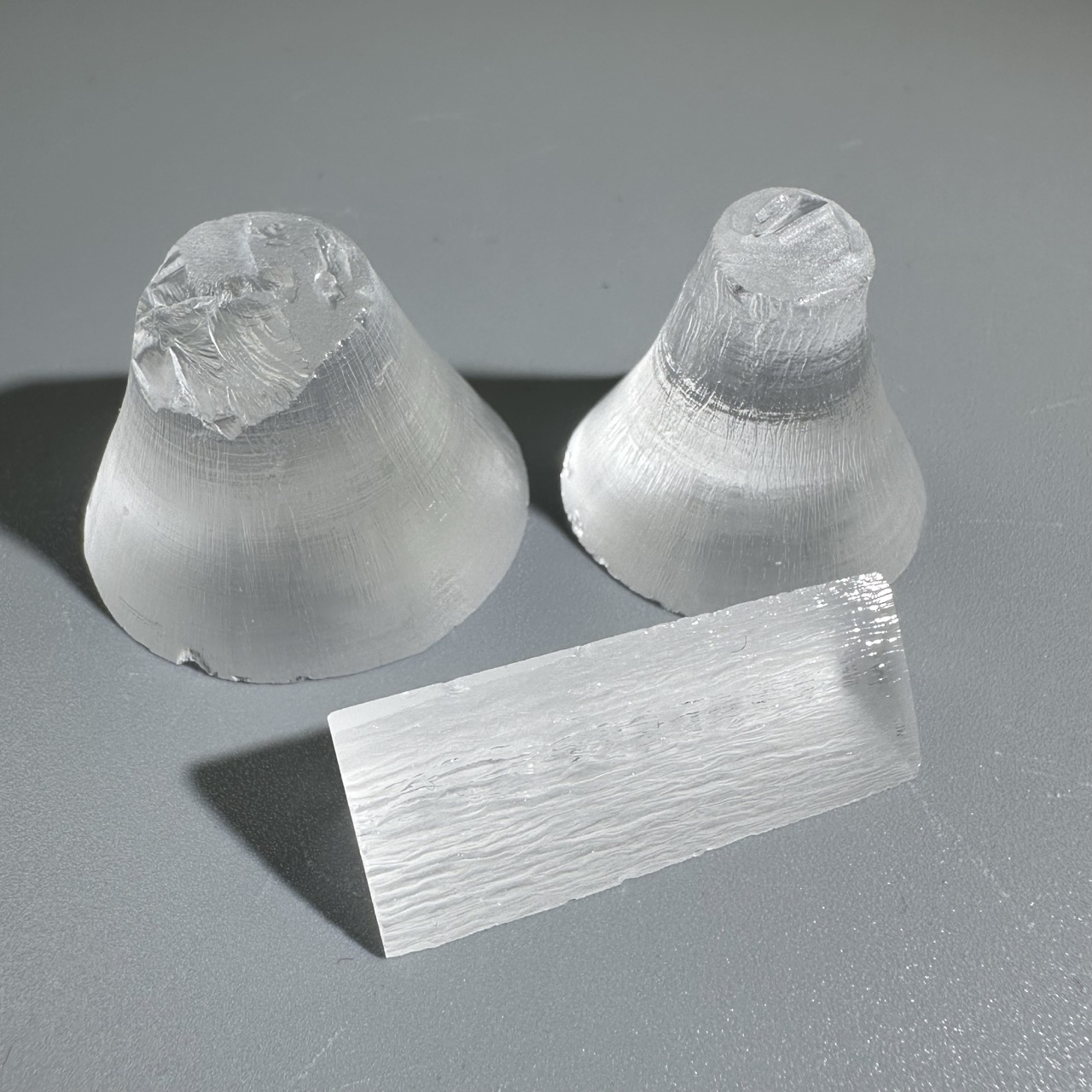

Ihe akwadoro

Igwe anya anya: quartz, microcrystalline, K9, wdg.

Ihe infrared: silicon, germanium, wdg.

Ọla: Aluminom, igwe anaghị agba nchara, titanium alloy, wdg.

kristal: YAG, silicon carbide otu-kristal, wdg.

Ihe siri ike/na-emebi emebi: Silicon carbide, wdg.

Ogo elu / nkenke

PV <10 nm

RMS ≤ 0.5 nm

Na-eme nchọpụta ikpe nke igwe ion Beam Polishing

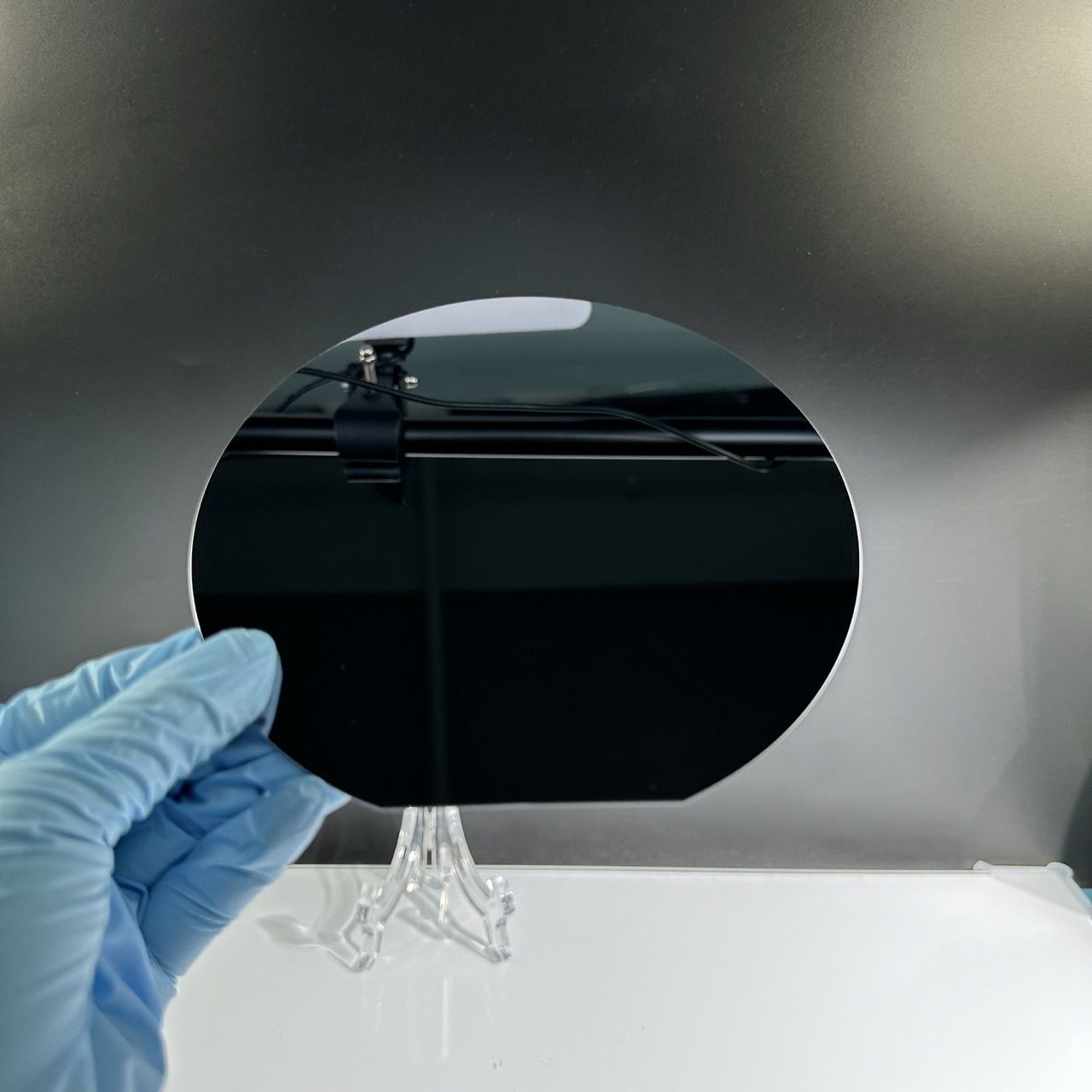

Ikpe 1 – Standard Flat Mirror

Ihe arụ ọrụ: D630 mm quartz flat

Nsonaazụ: PV 46.4 nm; RMS 4.63 nm

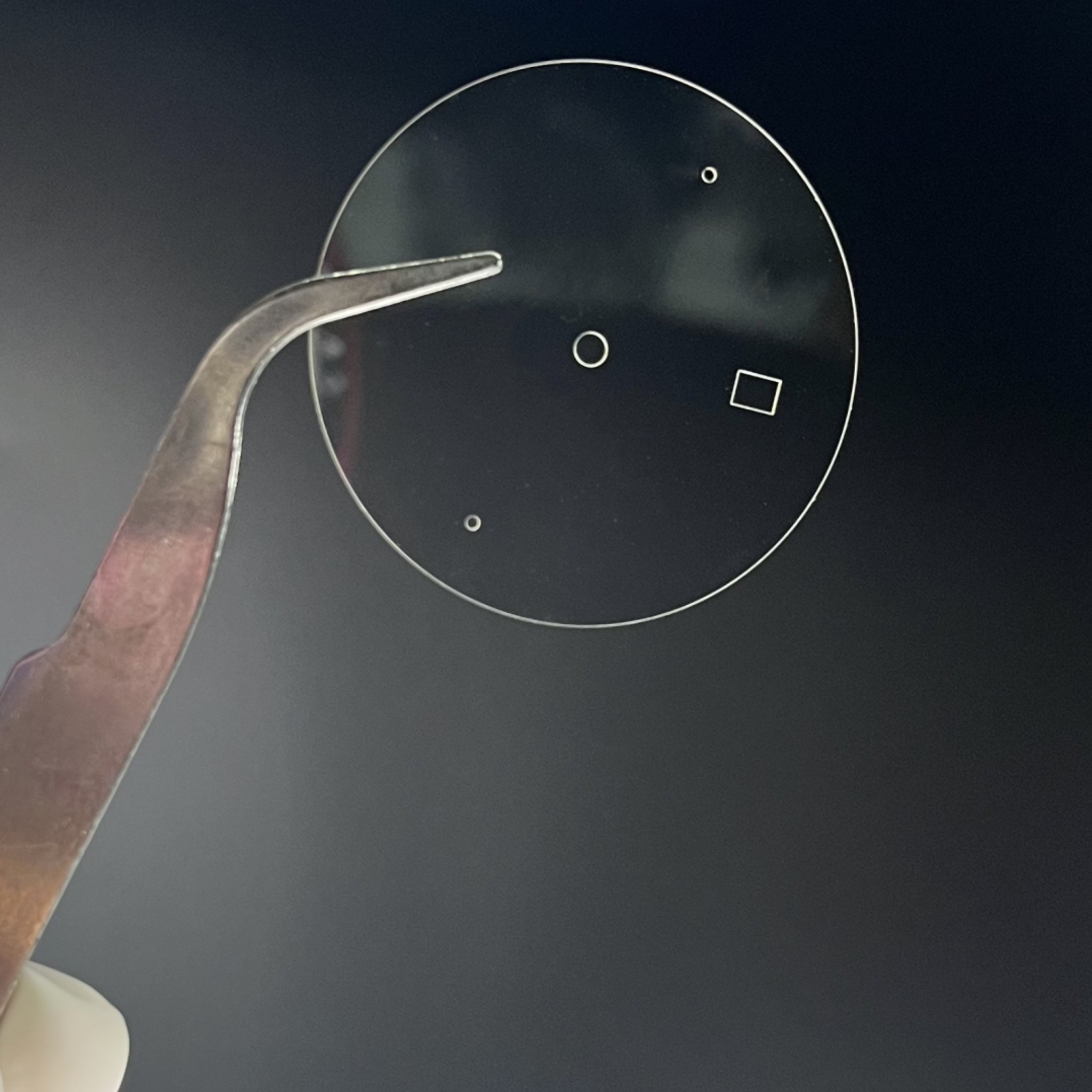

Ikpe 2 – X-ray Reflective mirror

Ihe eji arụ ọrụ: 150 × 30 mm silicon flat

Nsonaazụ: PV 8.3 nm; RMS 0.379 nm; Mkpọda 0.13 µrad

Ikpe nke 3 - Ngosipụta anya-Axis

Ihe eji arụ ọrụ: D326 mm na-anọghị na axis ala mirror

Nsonaazụ: PV 35.9 nm; RMS 3.9 nm

FAQ nke iko Quartz

FAQ – Igwe na-ekpo ọkụ ion Beam

Q1: Gịnị bụ ion beam polishing?

A1:Ion beam polishing bụ usoro na-abụghị kọntaktị nke na-eji ion agbadoro anya (dị ka argon ion) iji wepụ ihe dị na elu ọrụ. A na-eme ka ion ndị ahụ ọsọ ọsọ ma na-eduzi ya n'elu, na-eme ka mwepụ ihe dị n'ọkwa atomic, na-ebute mmecha nke ọma. Usoro a na-ewepụ nrụgide n'ibu na mmebi nke dị n'okpuru ala, na-eme ka ọ dị mma maka ngwa anya ngwa anya.

Q2: Kedu ụdị elu nke Ion Beam Polishing Machine nwere ike ime?

A2:NkeIgwe na-ekpo ọkụ ion Beamnwere ike hazie ihe dị iche iche na-ebupụta, gụnyere mfe ngwa anya components dị kaflat, spheres na prisms, yana mgbagwoju anya geometric dị kaaspheres, apụ-axis aspheres, nafreeform elu. Ọ dị irè karịsịa na ihe ndị dị ka enyo anya, infrared optics, metals, na ihe siri ike/na-agbaji agbaji.

Q3: Kedu ihe Ion Beam Polishing Machine nwere ike ịrụ ọrụ?

A3:NkeIgwe na-ekpo ọkụ ion Beamnwere ike ihicha ihe dị iche iche, gụnyere:

-

Igwe anya anya: quartz, microcrystalline, K9, wdg.

-

Ihe infrared: silicon, germanium, wdg.

-

Ọla: Aluminium, igwe anaghị agba nchara, titanium alloy, wdg.

-

Ihe kristal: YAG, silicon carbide otu-kristal, wdg.

-

Ihe ndị ọzọ siri ike/na-emebi emebi: Silicon carbide, wdg.

Gbasara anyị

XKH na-ahụ maka mmepe teknụzụ dị elu, mmepụta na ire nke enyo anya pụrụ iche na ihe kristal ọhụrụ. Ngwaahịa anyị na-eje ozi ngwa anya eletrọnịkị, ngwa eletrọnịkị ndị ahịa na ndị agha. Anyị na-enye ngwa anya sapphire, mkpuchi oghere ekwentị mkpanaaka, ceramics, LT, Silicon Carbide SIC, Quartz, na kristal semiconductor. Site na nka nka na akụrụngwa dị oke ọnụ, anyị na-eme nke ọma na nhazi ngwaahịa na-abụghị ọkọlọtọ, na-achọ ịbụ onye na-eduga optoelectronic ihe ụlọ ọrụ teknụzụ dị elu.