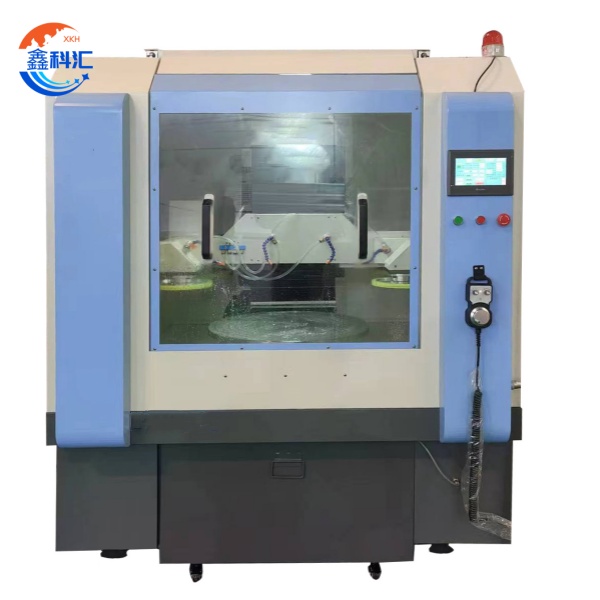

Ngwa mgbanaka wafer na-akpaghị aka na-arụ ọrụ nha 8inch/12inch wafer mgbanaka ịkpụ.

Usoro nka

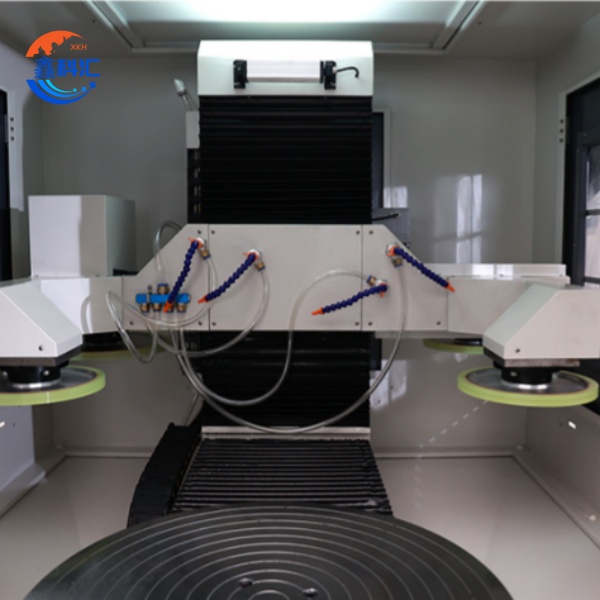

| Oke | Nkeji | Nkọwapụta |

| Oke arụrụ arụ ọrụ | mm | ø12" |

| Spindle | Nhazi | Otu Spindle |

| Ọsọ | 3,000-60,000 rpm | |

| Ike mmepụta | 1.8 kW (2.4 nhọrọ) na 30,000 min⁻¹ | |

| Max Blade Dia. | Ø58 mm | |

| X-Axis | Oke oke | 310 mm |

| Y-axis | Oke oke | 310 mm |

| Nkwalite nzọụkwụ | 0.0001 mm | |

| Ndokwa nke ziri ezi | ≤0.003 mm/310 mm, ≤0.002 mm/5 mm (otu njehie) | |

| Z-Axis | Mkpebi mmegharị | 0.00005 mm |

| Nkwagharị ugboro ugboro | 0.001 mm | |

| θ-Axis | Oke ntụgharị | 380 deg |

| Ụdị Spindle | Otu mkpịsị mkpịsị aka, nke nwere agụba siri ike maka ịkpụ mgbanaka | |

| Izi ezi mbelata mgbanaka | μm | ±50 |

| Ndozi wafer ziri ezi | μm | ±50 |

| Ịrụ otu Wafer | min/wafer | 8 |

| Ịrụ Ọrụ Multi-Wafer | A na-edozi ihe ruru wafer 4 n'otu oge | |

| Akụrụngwa arọ | kg | ≈3,200 |

| Akụkụ akụrụngwa (W×D×H) | mm | 2,730 × 1,550 × 2,070 |

Ụkpụrụ ọrụ

Sistemu na-enweta arụmọrụ mbelata pụrụ iche site na teknụzụ ndị a bụ isi:

1.Intelligent Motion Control System:

Mbanye moto ahịrị kwụ ọtọ dị elu ( kwugharịa izi ezi: ± 0.5μm)

· njikwa synchronous nke axis isii na-akwado atụmatụ trajectory dị mgbagwoju anya

· Real-oge vibration suppress algọridim n'ịhụ ọnwụ nkwụsi ike

2. Advanced Nchọpụta Sistemụ:

Ihe mmetụta ịdị elu laser 3D jikọtara ọnụ (nke ziri ezi: 0.1μm)

Ndokwa n'ọhụụ CCD dị elu (5 megapixels)

· Module nyocha ogo dị n'ịntanetị

3. Usoro akpaaka zuru oke:

Nbudata/ebutu akpaaka (ọkọlọtọ FOUP dakọtara)

· Usoro nhazi ọgụgụ isi

· Ngalaba nhicha mechiri emechi (ịdị ọcha: Klas 10)

Ngwa a na-ahụkarị

Akụrụngwa a na-enye uru dị ukwuu n'ofe ngwa nrụpụta semiconductor:

| Ubi ngwa | Ngwa usoro | Uru nka |

| Nrụpụta IC | 8/12 "Silicon Wafers | Na-akwalite nhazi nke lithography |

| Ngwaọrụ Ike | SiC/GaN Wafers | Na-egbochi ntụpọ ihu |

| Ihe mmetụta MEMS | SOI Wafers | Na-akwado ntụkwasị obi ngwaọrụ |

| Ngwa RF | GaAs Wafers | Na-eme ka arụmọrụ dị elu dị elu |

| Nkwakọ ngwaahịa dị elu | Wafers arụgharịrị | Na-abawanye mkpụrụ nkwakọ ngwaahịa |

Atụmatụ

1.Four-station nhazi maka elu nhazi arụmọrụ;

2.Stable TAIKO mgbanaka debonding na mwepụ;

3.High ndakọrịta na isi consumables;

4.Multi-axis synchronous trimming technology ana achi achi nkenke onu ọnwụ;

5.Fully akpaghị aka usoro eruba budata ebelata ọrụ ụgwọ;

6.Customized worktable imewe na-enyere kwụsie ike nhazi nke pụrụ iche owuwu;

Ọrụ

1.Mgbanaka-dobe nchọpụta usoro;

2.Automatic worktable nhicha;

3.Intelligent UV debonding usoro;

4.Operation ndekọ ndekọ;

5.Factory akpaaka modul mwekota;

Nkwenye ọrụ

XKH na-enye ọrụ nkwado zuru oke nke ndụ okirikiri emebere iji bulie arụmọrụ akụrụngwa yana arụmọrụ arụ ọrụ n'oge njem mmepụta gị.

1. Ọrụ nhazi

· Nhazi akụrụngwa ahaziri ahazi: Ndị otu injinia anyị na ndị ahịa na-arụkọ ọrụ ọnụ iji bulie usoro sistemụ (ịcha ọsọ, nhọrọ agụba, wdg) dabere na akụrụngwa akụrụngwa akọwapụtara (Si / SiC / GaAs) na usoro chọrọ.

· Nkwado Mmepe Usoro: Anyị na-enye nhazi nlele na akụkọ nyocha zuru ezu gụnyere nha roughness na maapụ ntụpọ.

· Mmepụta ihe eji eme ihe: Maka ihe ọhụrụ (dịka ọmụmaatụ, Ga₂O₃), anyị na ndị na-emepụta ihe na-emepụta ihe na-arụkọ ọrụ iji mepụta agụba / laser optics akọwapụtara ngwa.

2. Nkwado nka na ụzụ ọkachamara

Nkwado na saịtị raara onwe ya nye: Kenye ndị injinia agbaziri agbaziri maka usoro mgbago dị oke egwu (nke na-abụkarị izu 2-4), na-ekpuchi:

Nhazi akụrụngwa & nhazi nke ọma

Ọzụzụ ikike onye ọrụ

Ntuziaka ntinye ụlọ dị ọcha ISO Class 5

· Mmezi amụma: Nyocha ahụike nke nkeji nkeji na nyocha vibration na nchọpụta moto servo iji gbochie oge ọdịda na-enweghị atụmatụ.

Nleba anya n'ime anya: nleba anya arụmọrụ akụrụngwa n'oge site na ikpo okwu IoT anyị (JCFront Connect®) nwere ọkwa anomaly akpaaka.

3. Ọrụ agbakwunyere uru

Usoro ihe ọmụma usoro: Nweta 300+ ezi ntụziaka ịkpụchasị mma maka ihe dị iche iche (emelitere kwa nkeji iri na ise).

Nhazi okporo ụzọ teknụzụ: Ọdịnihu jiri ụzọ nkwalite ngwaike/software gosi itinye ego gị (dịka ọmụmaatụ, modul nchọpụta ntụpọ dabere AI).

· Nzaghachi ihe mberede: achọpụtara nchoputa dịpụrụ adịpụ nke awa 4 na awa 48 na saịtị (nkpuchi zuru ụwa ọnụ).

4. Akụrụngwa ọrụ

· Nkwenye arụmọrụ: Nkwekọrịta nkwekọrịta na ≥98% ngwa ngwa na oge nzaghachi SLA na-akwado.

Mmelite na-aga n'ihu

Anyị na-eme nyocha afọ ojuju ndị ahịa kwa afọ ma mejuputa atumatu Kaizen iji kwalite nnyefe ọrụ. Ndị otu R&D anyị na-atụgharị nghọta ubi ka ọ bụrụ nkwalite akụrụngwa - 30% nke nkwalite ngwa ngwa sitere na nzaghachi ndị ahịa.