Sistemụ Ntuzi Wafer maka Ntụgharị kristal

Okwu mmalite

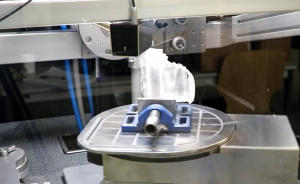

Ngwa nghazi Wafer bụ ngwaọrụ ziri ezi dabere na ụkpụrụ X-ray diffraction (XRD), nke a na-ejikarị eme ihe n'ichepụta semiconductor, ngwa anya, ceramik, na ụlọ ọrụ ihe ndị ọzọ kristal.

Ngwa ndị a na-ekpebi nghazi lattice kristal ma na-eduzi usoro ịkpụ ma ọ bụ nchacha nke ọma. Atụmatụ gụnyere:

- Ọnụ ọgụgụ dị oke mma:Nwere ike idozi ụgbọ elu crystallographic na mkpebi angular ruo 0.001°.

- Dakọtara nnukwu sample:Na-akwado wafers ruo 450 mm na dayameta na ịdị arọ nke kilogram 30, dabara maka ihe ndị dị ka silicon carbide (SiC), sapphire, na silicon (Si).

- Ihuenyo Modular:Arụmọrụ nwere ike ịgbasa gụnyere nyocha curve na-ama jijiji, nkewa ntụpọ elu 3D, na ngwaọrụ stacking maka nhazi ọtụtụ ihe nlele.

Isi Nka na ụzụ Parameters

| Otu parameter | Ụdị ụkpụrụ/Nhazi |

| Isi mmalite X-ray | Cu-Kα (0.4 × 1 mm focal spot), 30kV accelerating voltaji, 0-5 mA mgbanwe tube ugbu a |

| Mpaghara Angular | θ: -10° ruo +50°; 2θ: -10° ruo +100° |

| Izi ezi | Mkpebi tilt angle: 0.001°, nchọpụta ntụpọ elu: ± 30 arcseconds (mgbagwoju anya) |

| Ọsọ nyocha | Omega scan emechala nghazi lattice zuru oke na sekọnd ise; Nyocha Theta na-ewe ~ 1 nkeji |

| Sample Stage | V-groove, mmịpụta pneumatic, ntụgharị akụkụ ọtụtụ, dakọtara na wafers 2–8-inch |

| Ọrụ enwere ike ịgbasa | Nlebanya nhịahụ, maapụ 3D, ngwaọrụ stacking, nchọpụta ntụpọ anya (nyocha, GBs) |

Ụkpụrụ ọrụ

1. Ụlọ ọrụ X-ray Diffraction Foundation

- X-ray na-emekọrịta ihe na nuclei atomic na eletrọn na lattice kristal, na-emepụta ụkpụrụ dị iche iche. Iwu Bragg (nλ = 2d sinθ) na-achịkwa mmekọrịta dị n'etiti akụkụ dị iche iche (θ) na oghere lattice (d).

Ndị na-achọpụta ihe na-ejide ụkpụrụ ndị a, bụ ndị a na-enyocha iji wughachi ihe owuwu crystallographic.

2. Teknụzụ nyocha Omega

- Igwe kristal na-aga n'ihu na-atụgharị gburugburu axis a kapịrị ọnụ ka ụzarị X na-enye ya ìhè.

- Ndị na-achọpụta ihe na-anakọta akara diffraction n'ofe ọtụtụ ụgbọ elu crystallographic, na-eme ka mkpebi ntụgharị uche zuru oke na 5 sekọnd.

3. Rocking Curve Analysis

- Nkuku kristal edobere nwere akụkụ ihe omume X-ray dị iche iche iji tụọ obosara kacha elu (FWHM), na-enyocha ntụpọ lattice na nsogbu.

4. Njikwa akpaaka

- PLC na ihuenyo mmetụ aka na-eme ka akụkụ ndị e debere ahazi, nzaghachi ozugbo, na ijikọ na igwe ịcha ihe maka njikwa aka-emechi.

Uru na atụmatụ

1. Nkenke na arụmọrụ

- Izi ezi akụkụ ± 0.001°, mkpebi nchọpụta ntụpọ <30 sekọnd.

- Ọsọ omega nyocha dị 200 × ọsọ ọsọ karịa nyocha Theta ọdịnala.

2. Modularity na Scalability

- Enwere ike ịgbasawanye maka ngwa pụrụ iche (dịka ọmụmaatụ, SiC wafers, agụba turbine).

- Na-ejikọta ya na sistemụ MES maka nleba anya mmepụta oge.

3. Ndakọrịta na nkwụsi ike

- Na-anabata ihe nlere anya n'ụdị oge niile (dịka ọmụmaatụ, ingots sapphire gbawara agbawa).

- Nhazi nke ikuku jụrụ oyi na-ebelata mkpa nlekọta.

4. Ọrụ ọgụgụ isi

- Otu-pịa calibration na nhazi ọtụtụ ọrụ.

- Ndozi onwe ya na kristal ntụaka iji wedata njehie mmadụ.

Ngwa

1. Semiconductor Manufacturing

- Ntuzi aka wafer dicing: na-ekpebi Si, SiC, ntụzịaka wafer GaN maka ịrụ ọrụ kacha mma.

- Nkewa adịghị mma: Na-achọpụta ọnyà dị n'elu ma ọ bụ mwepu iji kwalite mkpụrụ mgbawa.

2. Ngwa ngwa anya

- Kristal na-adịghị adị (dịka, LBO, BBO) maka ngwaọrụ laser.

- Ihe nrịbama n'elu sapphire wafer maka ihe ọkụ ọkụ.

3. Ceramics na Composites

- Nyochaa ntụzịaka ọka na Si3N4 na ZrO2 maka ngwa okpomọkụ dị elu.

4. Nyocha na njikwa mma

- Ụlọ akwụkwọ mahadum/ụlọ nyocha maka mmepe ihe ọhụrụ (dịka ọmụmaatụ, alloys entropy dị elu).

- Industrial QC iji hụ na ogbe agbanwe agbanwe.

Ọrụ XKH

XKH na-enye nkwado teknụzụ ndụ okirikiri zuru oke maka ngwa nghazi wafer, gụnyere nrụnye, njikarịcha oke usoro, nyocha usoro mkpagharị na maapụ ntụpọ elu 3D. A na-enye azịza ahaziri ahazi (dịka, teknụzụ ingot stacking technology) iji kwalite arụmọrụ semiconductor na ngwa anya ihe karịrị 30%. Ndị otu raara onwe ha nye na-eduzi ọzụzụ na saịtị, ebe 24/7 nkwado dịpụrụ adịpụ na ngwa ngwa ngbanwe akụkụ mapụtara na-ahụ na a pụrụ ịdabere na akụrụngwa.