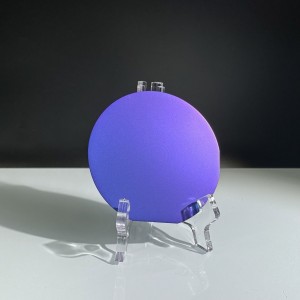

Ihe nkiri SiO2 Thin Thermal Oxide Silicon wafer 4inch 6inch 8inch 12inch

Ewebata igbe wafer

Usoro bụ isi nke ịmepụta silicon wafers na-agụnyekarị usoro ndị a: uto silicon monocrystalline, ịkpụ n'ime wafers, polishing, ihicha na oxidation.

Uto silicon monocrystalline: Nke mbụ, silicon monocrystalline na-eto na oke okpomọkụ site na ụzọ dị ka usoro Czochralski ma ọ bụ usoro Float-zone. Usoro a na-enyere aka nkwadebe nke silicon single crystals na ịdị ọcha dị elu na iguzosi ike n'ezi ihe.

Dicing: silicon monocrystalline toro eto na-adịkarị n'ụdị cylindrical ma ọ dị mkpa ka e bee ya n'ime obere wafer iji mee ihe dị ka mkpụrụ wafer. A na-ejikarị ihe na-egbutu diamond eme ịkpụ.

Ntucha: elu nke wafer ịkpụ nwere ike ghara ịdị na-adabara ma na-achọ ihicha kemịkalụ-mechanical iji nweta elu dị larịị.

Nhicha: A na-ehicha wafer a na-egbu maramara iji wepụ ihe adịghị ọcha na uzuzu.

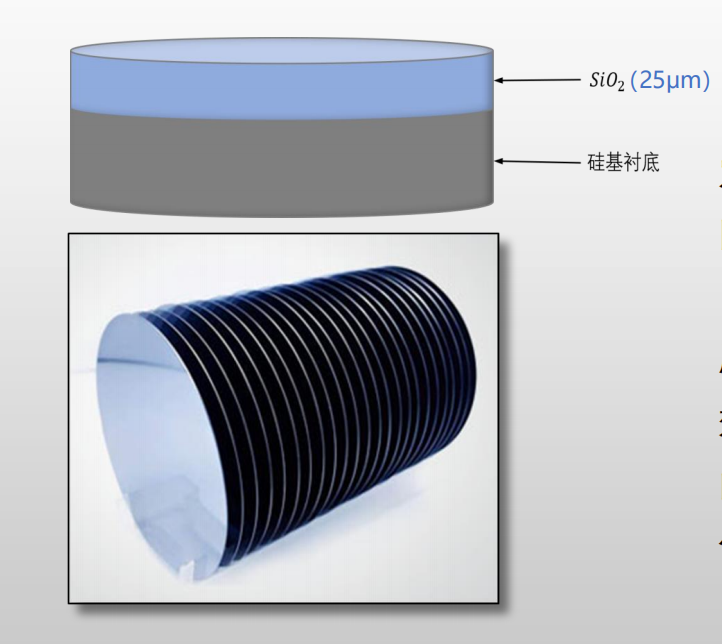

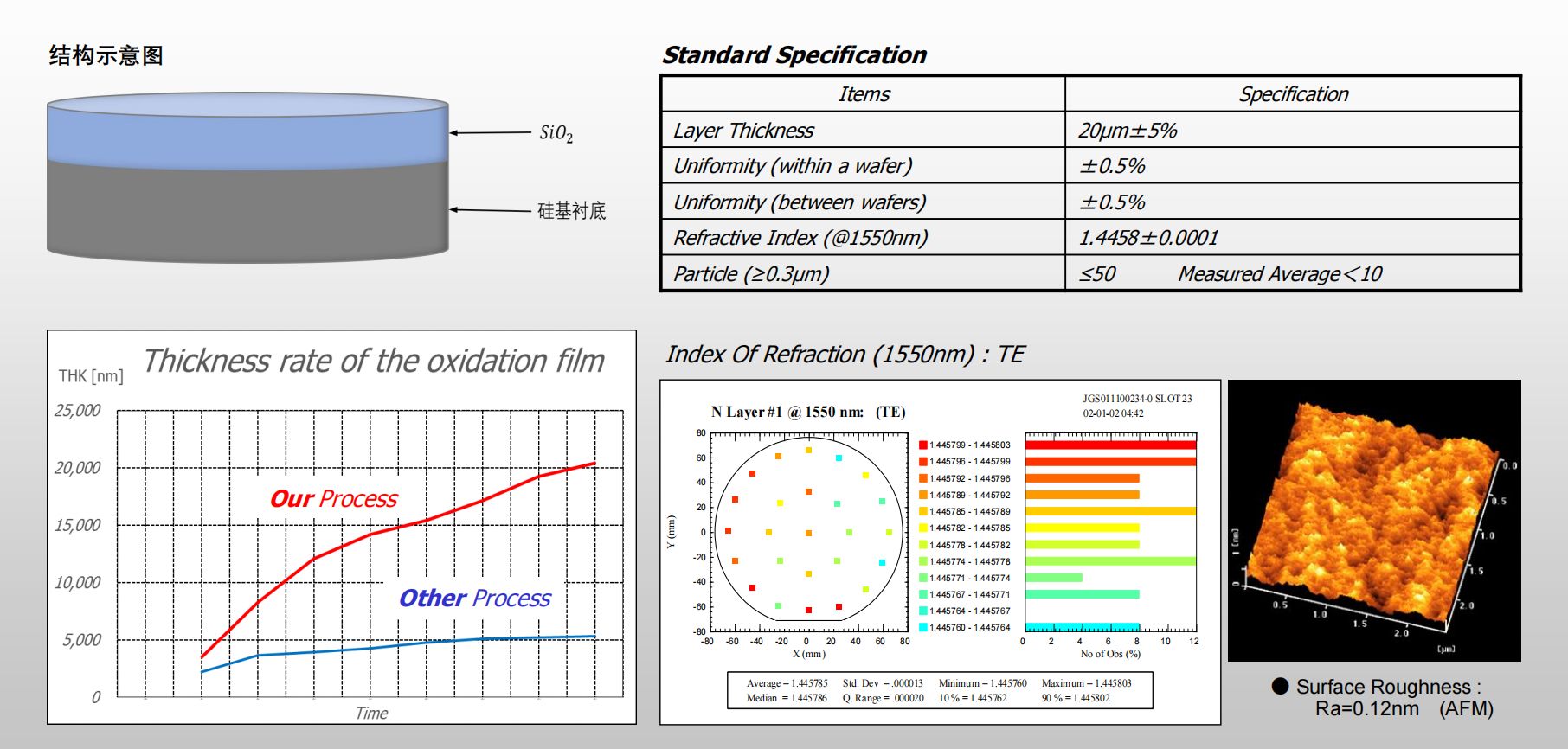

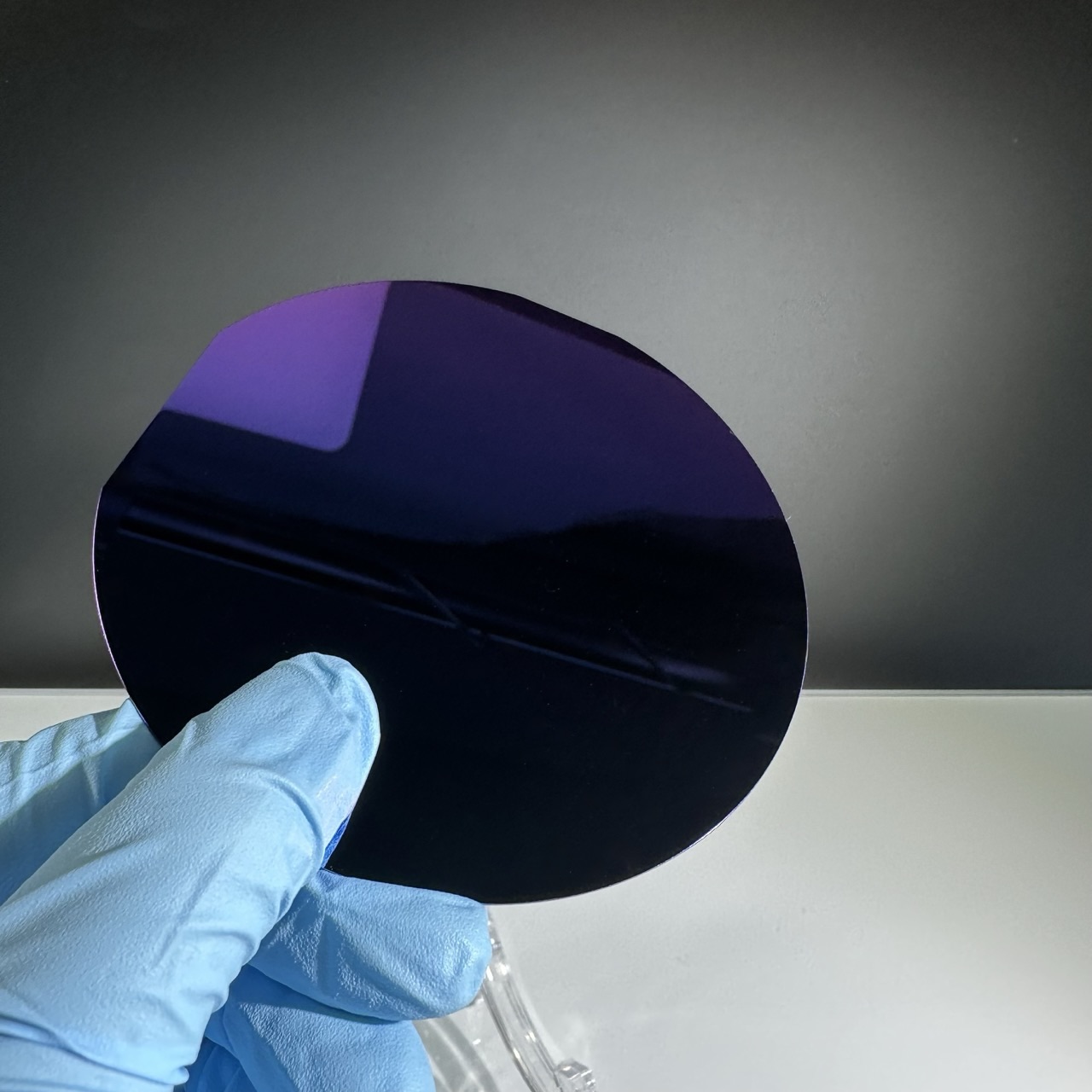

Oxidizing: N'ikpeazụ, a na-etinye silicon wafers n'ime ọkụ ọkụ dị elu maka ọgwụgwọ oxidizing iji mepụta oyi akwa mkpuchi silicon dioxide iji meziwanye ihe eletrik ya na ike ọrụ ya, yana ịrụ ọrụ dị ka ihe mkpuchi mkpuchi na sekit jikọtara ọnụ.

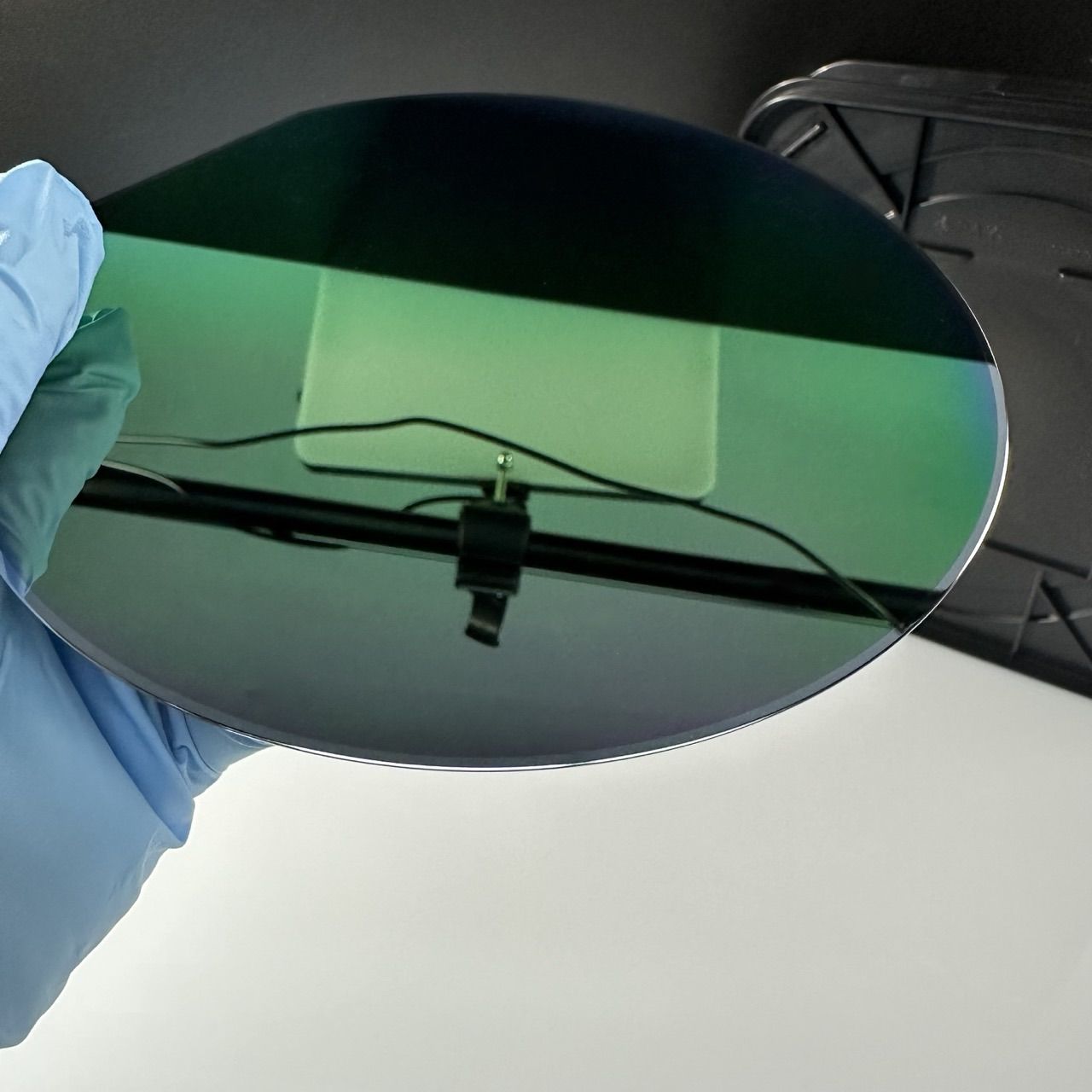

Isi ojiji nke silicon wafers oxidized gụnyere imepụta sekit jikọtara ọnụ, imepụta mkpụrụ ndụ anyanwụ, na imepụta ngwaọrụ eletrọnịkị ndị ọzọ. A na-eji silicon oxide wafers eme ihe n'ọtụtụ ebe n'ọhịa nke semiconductor n'ihi njirimara akụrụngwa ha dị mma, nkwụsi ike akụkụ na kemịkal, ike ịrụ ọrụ na oke okpomọkụ na nrụgide dị elu, yana ezigbo mkpuchi na ngwa anya.

Ya uru na-agụnye a zuru ezu crystal Ọdịdị, dị ọcha chemical mejupụtara, kpọmkwem akụkụ, ezi n'ibu Njirimara, wdg Ndị a na-eme ka silicon oxide wafers karịsịa adabara maka imewe nke elu-arụmọrụ integrated sekit na ndị ọzọ microelectronic ngwaọrụ.

Eserese zuru ezu