SiC seramiiki efere / tray maka 4inch 6inch wafer njide maka ICP

SiC seramiiki efere Abstract

Efere seramiiki SiC bụ akụrụngwa na-arụ ọrụ dị elu emebere site na Silicon Carbide dị ọcha, emebere maka ojiji na gburugburu ọkụ, kemịkalụ na igwe. N'ịbụ onye a ma ama maka isi ike ya pụrụ iche, conductivity thermal, na corrosion resistance, a na-eji efere SiC eme ihe n'ọtụtụ ebe dị ka onye na-ebu wafer, susceptor, ma ọ bụ ihe nhazi na semiconductor, LED, photovoltaic, na ụlọ ọrụ ikuku.

Site na nkwụsi ike dị egwu ruo 1600 Celsius C yana nguzogide dị mma maka gas na-emeghachi omume na gburugburu plasma, efere SiC na-eme ka arụ ọrụ na-agbanwe agbanwe n'oge etching dị elu, ntinye na mgbasa ozi. Nnukwu microstructure ya dị oke, nke na-enweghị oghere na-ebelata ọgbọ irighiri ihe, na-eme ka ọ dị mma maka ngwa dị ọcha nke ukwuu na oghere ma ọ bụ ntọala ụlọ dị ọcha.

Ngwa seramiiki SiC

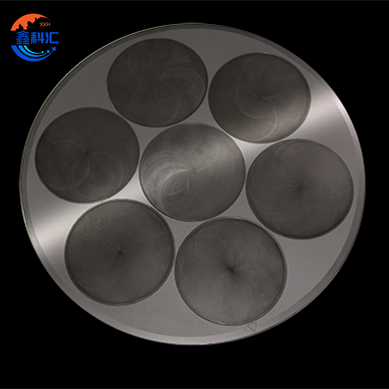

1. Semiconductor Manufacturing

A na-ejikarị efere seramiiki SiC eme ihe dị ka ndị na-ebu wafer, ndị susceptors, na efere pedestal na ngwa nrụpụta semiconductor dị ka CVD (Chemical Vapor Deposition), PVD (Ntube Vapor anụ ahụ), na usoro etching. Nrụpụta ọkụ ha dị mma na mgbasawanye ọkụ dị ala na-enye ha ohere ịnọgide na-enwe nkesa otu okpomọkụ, nke dị oke mkpa maka nhazi wafer dị elu. Nguzogide SiC na gas na-emebi emebi na plasmas na-eme ka ọ dị ogologo ndụ na gburugburu ebe siri ike, na-enyere aka belata mmetọ ahụ na mmezi akụrụngwa.

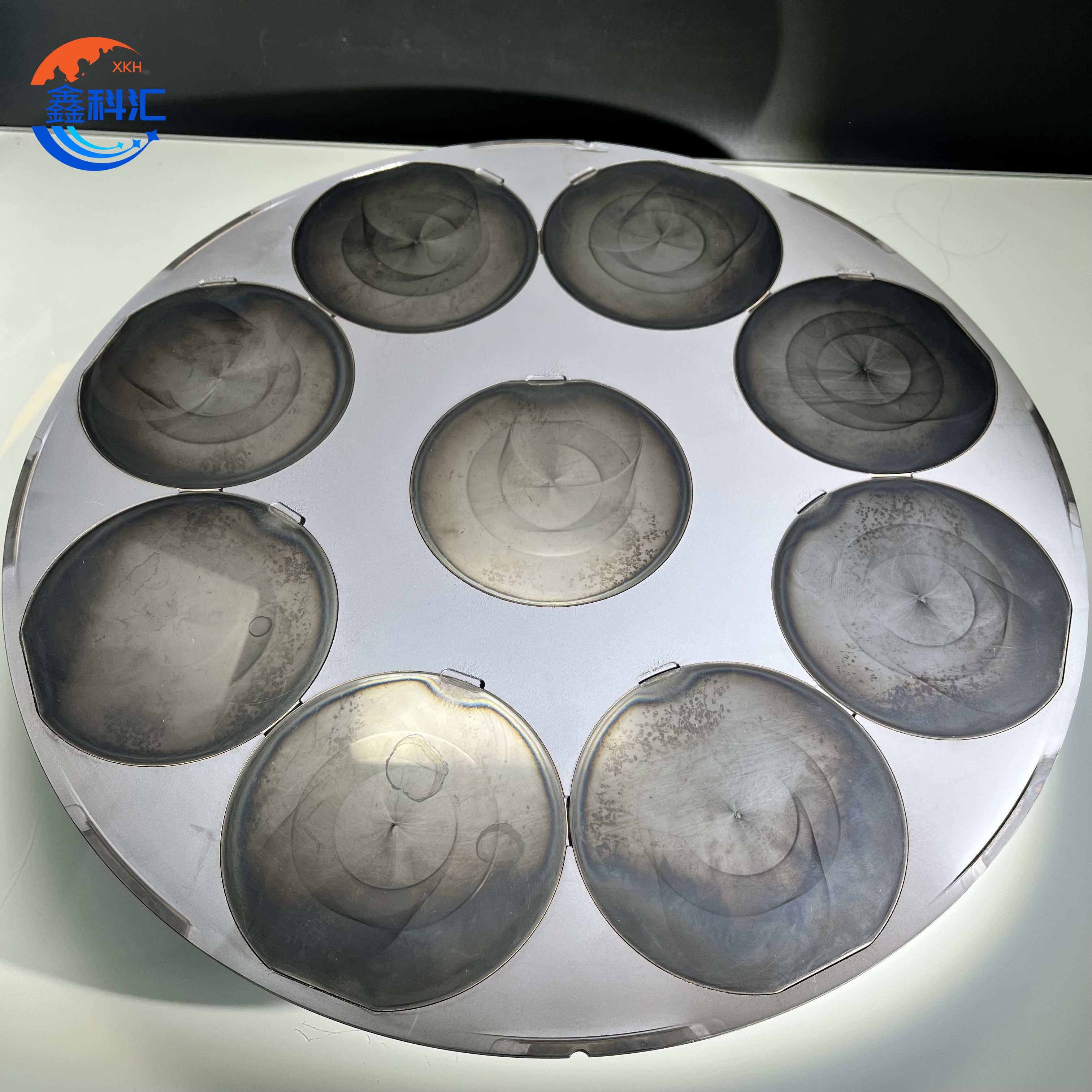

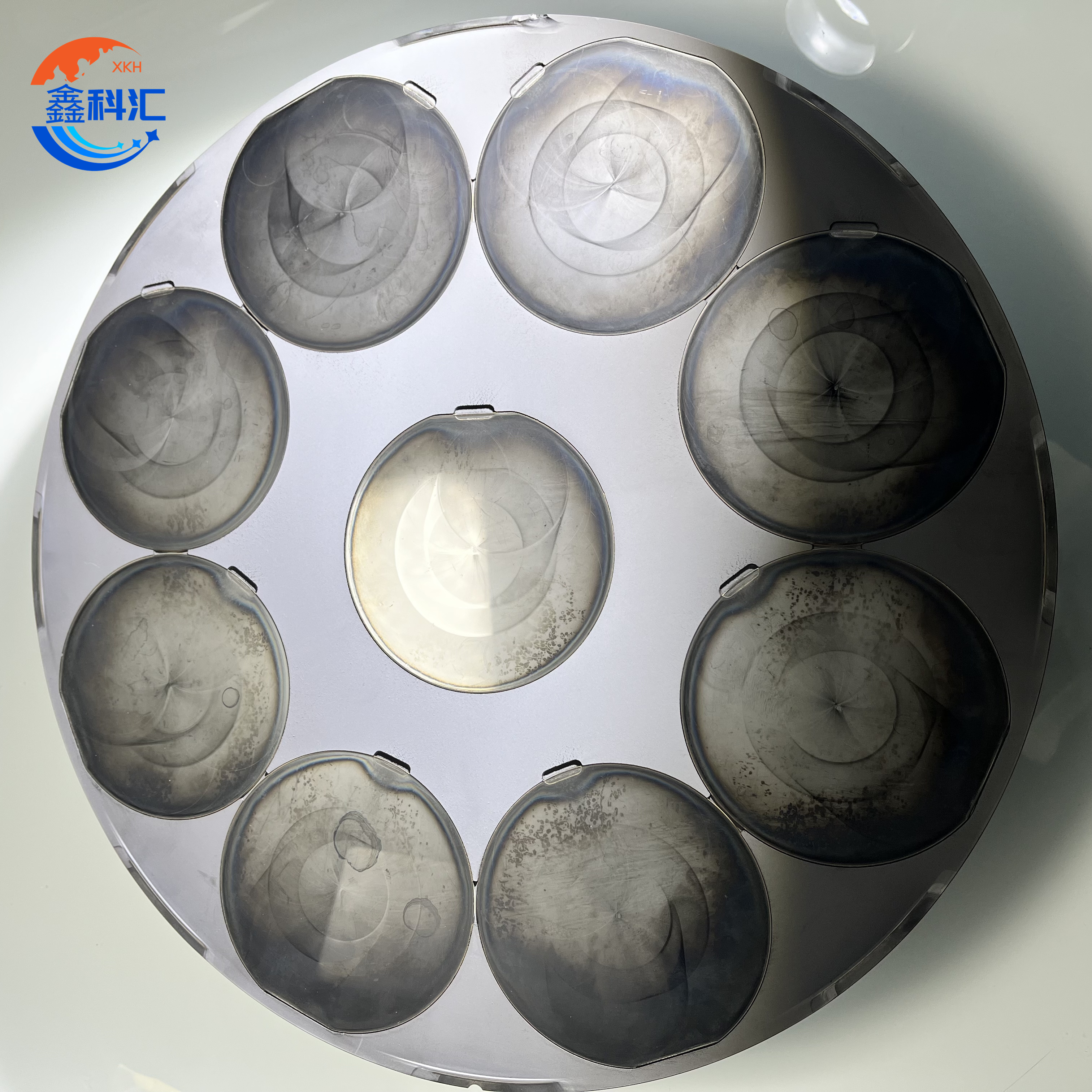

2. Ụlọ ọrụ LED - ICP Etching

Na mpaghara nrụpụta LED, efere SiC bụ ihe ndị bụ isi na sistemụ etching ICP (Inductively Coupled Plasma). Na-arụ ọrụ dị ka ndị na-ejide wafer, ha na-enye ikpo okwu kwụsiri ike na nke siri ike iji kwado sapphire ma ọ bụ GaN wafer n'oge nhazi plasma. Nguzogide plasma ha dị mma, ịdị larịị elu na nkwụsi ike akụkụ na-enyere aka hụ na izi ezi na ịdị n'otu dị elu, na-eduga n'ịba ụba mkpụrụ na arụmọrụ ngwaọrụ na ibe LED.

3. Photovoltaics (PV) na ike anyanwụ

A na-ejikwa efere seramiiki SiC na-emepụta cell cell anyanwụ, karịsịa n'oge okpomọkụ dị elu na nkwụsịtụ. Ha inertness na elu okpomọkụ na ike iguzogide warping na-eme ka nhazi nke silicon wafers na-agbanwe agbanwe. Ọzọkwa, obere ihe ize ndụ mmetọ ha dị oke mkpa maka ịnọgide na-arụ ọrụ nke mkpụrụ ndụ fotovoltaic.

SiC seramiiki efere Njirimara

1. Ike Mechanical pụrụiche na isi ike

Efere seramiiki SiC na-egosipụta ike arụ ọrụ dị elu, yana ụdị ike mgbanwe karịrị 400 MPa na ike Vickers ruru> 2000 HV. Nke a na-eme ka ha na-eguzogide ike nke ukwuu na-eyi uwe, abrasion, na nrụrụ, na-eme ka ndụ ogologo ndụ dị ogologo ọbụna n'okpuru ibu dị elu ma ọ bụ ịgba ígwè ọkụ ugboro ugboro.

2. High Thermal Conductivity

SiC nwere ezigbo ọkụ eletrik (nke na-abụkarị 120-200 W / m·K), na-enye ya ohere kesaa okpomọkụ n'ofe ya. Ngwongwo a dị oke egwu na usoro dị ka etching wafer, nkwụnye ego, ma ọ bụ ịmegharị ihe, ebe otu ọnọdụ okpomọkụ na-emetụta mkpụrụ ngwaahịa na ịdịmma.

3. Elu Thermal kwụsie ike

Site na ebe mgbaze dị elu (2700°C) yana ọnụọgụ dị ala nke mgbasawanye thermal (4.0 × 10⁻⁶/K), efere seramiiki SiC na-edobe izi ezi akụkụ na nguzozi n'usoro n'okpuru usoro kpo oku na oyi. Nke a na-eme ka ha dị mma maka ngwa n'ime ọkụ ọkụ dị elu, oghere oghere, na gburugburu plasma.

| Nka nka | ||||

| Index | Nkeji | Uru | ||

| Aha ihe | Mmeghachi omume Sintered Silicon Carbide | Silicon Carbide Sintered enweghị nrụgide | Silicon Carbide recrystalized | |

| Ihe mejupụtara | RBSiC | SSiC | R-SiC | |

| Njupụta nnukwu | g/cm3 | 3 | 3.15 ± 0.03 | 2.60-2.70 |

| Ike Flexural | MPa (kpsi) | 338 (49) | 380 (55) | 80-90 (20°C) 90-100(1400°C) |

| Ike mkpakọ | MPa (kpsi) | 1120 (158) | 3970 (560) | > 600 |

| Isi ike | Kpupu | 2700 | 2800 | / |

| Na-agbaji Tenacity | MPa m1/2 | 4.5 | 4 | / |

| Nrụpụta okpomọkụ | W/mk | 95 | 120 | 23 |

| Ọnụọgụ nke Thermal Mgbasawanye | 10-6.1/°C | 5 | 4 | 4.7 |

| Okpomọkụ akọwapụtara | Joule/g 0k | 0.8 | 0.67 | / |

| Oke okpomọkụ na ikuku | ℃ | 1200 | 1500 | 1600 |

| Modul na-agbanwe | Gpa | 360 | 410 | 240 |

SiC seramiiki efere ajụjụ&A

Ajụjụ: Gịnị bụ Njirimara nke silicon carbide efere?

A: A maara efere silicon carbide (SiC) maka ike ha dị elu, ike siri ike na nkwụsi ike ha. Ha na-enye conductivity thermal magburu onwe ya na mgbasawanye ọkụ dị ala, na-ahụ na arụmọrụ a pụrụ ịdabere na ya n'okpuru oke okpomọkụ. SiC bụkwa kemịkalụ inert, na-eguzogide acids, alkalis, na gburugburu plasma, na-eme ka ọ dị mma maka semiconductor na nhazi LED. Nnukwu elu ya dị larịị na-ebelata ọgbọ urughuru, na-ejigide ndakọrịta ụlọ dị ọcha. A na-eji efere SiC eme ihe n'ọtụtụ ebe dị ka ndị na-ebu wafer, susceptors, na ihe nkwado na gburugburu okpomọkụ na gburugburu ebe obibi na-emebi emebi n'ofe semiconductor, fotovoltaic, na aerospace.