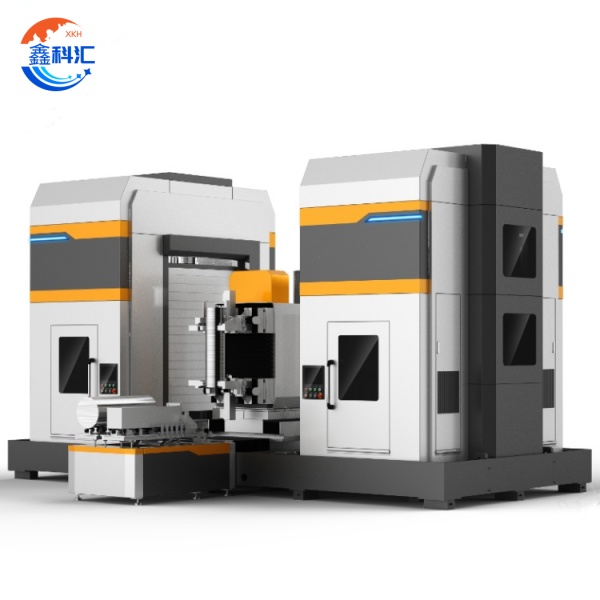

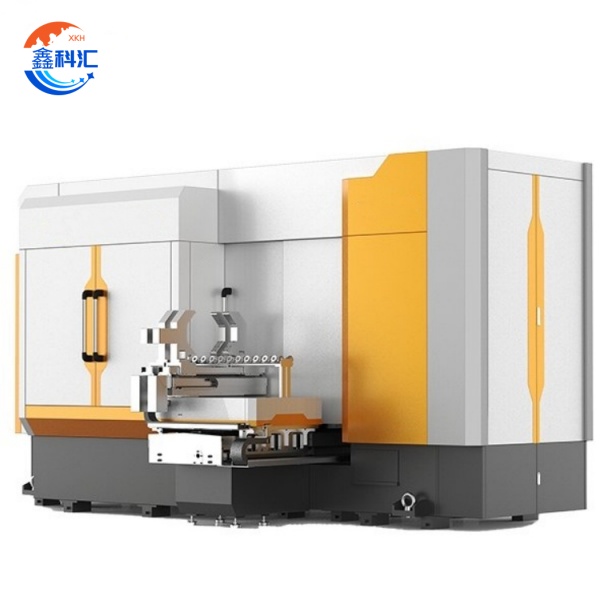

Ugboro abụọ ọdụ square igwe monocrystalline silicon mkpanaka nhazi 6/8/12 inch elu flatness Ra≤0.5μm

Njirimara akụrụngwa:

(1) Nhazi mekọrịta ọdụ ọdụ abụọ

· Ugboro abụọ arụmọrụ: Nhazi oge nke abụọ silicon mkpara (Ø6"-12") na-abawanye arụpụtaghị site 40% -60% vs. Simplex ngwá.

· Njikwa onwe: ọdụ ụgbọ ala ọ bụla nwere ike ịhazigharị akụkụ nke ịkpụ (mgbagwoju anya, ọsọ nri) iji mee mgbanwe na nkọwa mkpanaka silicon dị iche iche.

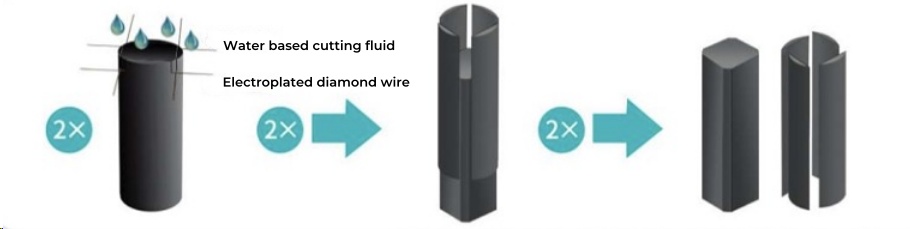

(2) Mbelata nkenke dị elu

· Akụkụ ziri ezi: square mmanya n'akụkụ anya ndidi ± 0.15mm, nso ≤0.20mm.

· Àgwà elu: mbelata nkwụsịtụ <0.5mm, belata ọnụ ọgụgụ nke egweri na-esote.

(3) njikwa ọgụgụ isi

· Mbelata ihe na-agbanwe agbanwe: nleba anya n'ezie nke silicon mkpanaka morphology, mgbanwe dị ike nke ụzọ ịkpụ (dị ka nhazi eriri silicon bent).

Ihe nchọta data: dekọọ paramita nhazi nke mkpanaka silicon ọ bụla iji kwado docking sistemụ MES.

(4) Ọnụ ego erimeri dị ala

· Oriri waya diamond: ≤0.06m/mm (ogologo mkpanaka silicon), dayameta waya ≤0.30mm.

· Mgbasa oyi: Usoro nzacha na-agbatị ndụ ọrụ ma belata mkpofu mmiri mmiri.

Uru teknụzụ na mmepe:

(1) Ịcha teknụzụ kacha mma

- Multi-line ọnwụ: 100-200 diamond ahịrị na-eji yiri, na ọnwụ ọsọ bụ ≥40mm / min.

- Nchekwa nchekasị: Sistemụ nhazi nhazi nke mechiri emechi (± 1N) iji belata ihe ize ndụ nke ịgbaji waya.

(2) Mgbatị ndakọrịta

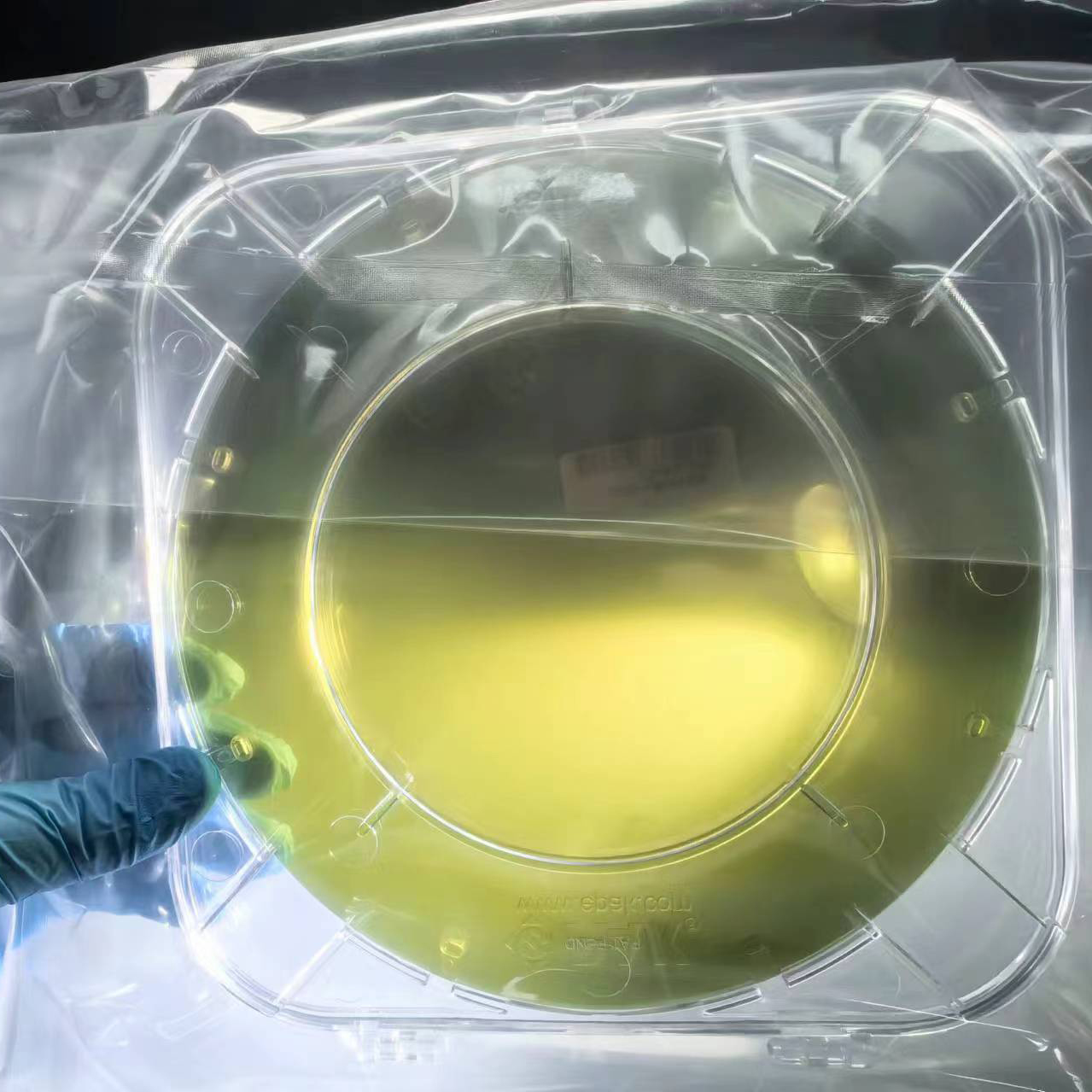

- Ngbanwe ihe: Nkwado silicon ụdị P-ụdị / N-ụdị monocrystalline, dakọtara na TOPCon, HJT na mkpanaka silicon batrị ndị ọzọ dị elu.

- Mgbanwe size: silicon mkpanaka ogologo 100-950mm, square mkpanaka akụkụ anya 166-233mm mgbanwe.

(3) nkwalite akpaaka

- Nbudata na nbudata robot: ntinye akpaaka / nbudata nke mkpanaka silicon, tie ≤3 nkeji.

- Nchọpụta ọgụgụ isi: Nlekọta amụma iji belata oge ezumike na-enweghị atụmatụ.

(4) Ndị isi ụlọ ọrụ

- Nkwado Wafer: nwere ike hazie ≥100μm ultra-thin silicon na mkpanaka mkpanaka, ọnụego mbelata <0.5%.

- Nkwalite oriri ike: ike oriri kwa nkeji nke mkpanaka silicon na-ebelata 30% (vs. ngwa ọdịnala).

Nka nka:

| Aha oke | Uru ndeksi |

| Ọnụọgụ mmanya ahaziziri | 2 iberibe / set |

| Ogologo ogologo mmanya na-arụ ọrụ | 100-950mm |

| Oke oke igwe | 166-233mm |

| Ịcha ọsọ | ≥40mm/min |

| Ọsọ waya diamond | 0 ~ 35m/s |

| Dayameta diamond | 0.30 mm ma ọ bụ obere |

| Oriri ahịrị | 0.06 m / mm ma ọ bụ obere |

| Dayameta mkpanaka gburugburu dakọtara | Dayameta mkpanaka mkpanaka agwụla +2mm, Gbaa mbọ hụ na ọnụego ngafe polishing |

| Mbelata nbibi njikwa | Raw onu ≤0.5mm, Enweghị chipping, elu elu mma |

| Iri n'ogologo Arc | Ogologo amụma <1.5mm, Ewezuga mgbagha mkpanaka silicon |

| Akụkụ igwe (otu igwe) | 4800×3020×3660mm |

| Mkpokọta ike gosiri | 56kW |

| Nwụrụ anwụ arọ nke akụrụngwa | 12t |

Tebụlụ nrịbama nke nrụzi ọrụ:

| Ihe nkenke | Oke nnabata |

| Nkwenye oke mmanya square | ± 0.15mm |

| Ogwe ihu akụkụ square | ≤0.20mm |

| Akụkụ n'akụkụ niile nke mkpanaka square | 90°±0.05° |

| Flatness nke square mkpanaka | ≤0.15mm |

| Robot kwụziri izi ezi ugboro ugboro | ± 0.05mm |

Ọrụ XKH:

XKH na-enye ọrụ okirikiri zuru oke maka igwe mono-crystalline silicon dual- stations, gụnyere nhazi ngwa ngwa (dakọtara na nnukwu mkpanaka silicon), nhazi usoro (ịchacha mma mma), ọzụzụ arụ ọrụ na nkwado ahịa mgbe emechara (nchịkọta akụkụ isi, nchọpụta dịpụrụ adịpụ), na-eme ka ndị ahịa nweta nnukwu mkpụrụ (> 99%) na mmepụta ọnụ ahịa dị ala, na inye nkwalite teknụzụ dị ka AI. Oge nnyefe bụ ọnwa 2-4.

Eserese zuru ezu