Usoro CVD maka imepụta akụrụngwa SiC dị ọcha na ọkụ ọkụ silicon carbide na 1600 ℃

Ụkpụrụ ọrụ:

1. Precursor ọkọnọ. A na-agwakọta isi iyi silicon (dịka ọmụmaatụ SiH₄) na isi iyi carbon (dịka ọmụmaatụ C₃H₈) gas na oke nha ma tinye ya n'ime ụlọ mmeghachi omume.

2. Igwe ọkụ dị elu: N'ebe okpomọkụ dị elu nke 1500 ~ 2300 ℃, ikuku gas na-emepụta Si na C na-arụ ọrụ atọm.

3. Mmeghachi omume n'elu: Si na C atọm na-edebe n'elu mkpụrụ n'elu na-etolite a SiC crystal oyi akwa.

4. Ụtọ kristal: Site na njikwa nke gradient okpomọkụ, ikuku gas na nrụgide, iji nweta ọganihu ntụziaka n'akụkụ c axis ma ọ bụ axis.

Igodo akara:

Okpomọkụ: 1600 ~ 2200 ℃ (> 2000 ℃ maka 4H-SiC)

· Nrụgide: 50 ~ 200mbar (obere nrụgide iji belata gas nucleation)

Ogo gas: Si / C≈1.0 ~ 1.2 (iji zere ntụpọ Si ma ọ bụ C)

Isi atụmatụ:

(1) kristal àgwà

Ngosi obere ntụpọ: njupụta microtubule <0.5cm ⁻², njupụta njupụta <10⁴ cm⁻².

Ụdị njikwa polycrystalline: nwere ike itolite 4H-SiC (isi), 6H-SiC, 3C-SiC na ụdị kristal ndị ọzọ.

(2) Nrụ ọrụ akụrụngwa

Elu okpomọkụ kwụsie ike: graphite induction kpo oku ma ọ bụ iguzogide kpo oku, okpomọkụ> 2300 ℃.

Njikwa Uniformity: mgbanwe okpomọkụ ± 5 ℃, ọnụego uto 10 ~ 50μm / h.

Sistemụ gas: High precision mass flowmeter (MFC), ịdị ọcha gas ≥99.999%.

(3) Uru teknụzụ

Ịdị ọcha dị elu: Ntinye uche adịghị ọcha n'azụ <10¹⁶ cm⁻³ (N, B, wdg).

Nnukwu nha: Nkwado 6 "/ 8" SiC mkpụrụ mkpụrụ.

(4) Ike oriri na ọnụ ahịa

Eriri ike dị elu (200 ~ 500kW · h kwa ọkụ), na-aza 30% ~ 50% nke mmepụta ego nke mkpụrụ SiC.

Ngwa isi:

1. Ihe ntinye ike nke semiconductor: SiC MOSFETs maka ịmepụta ụgbọ ala eletrik na fotovoltaic inverters.

2. Rf ngwaọrụ: 5G base station GaN-on-SiC epitaxial substrate.

Ngwaọrụ gburugburu 3.Extreme: ihe mmetụta okpomọkụ dị elu maka ikuku ikuku na ike nuklia.

Nkọwa nka nka:

| Nkọwapụta | Nkọwa |

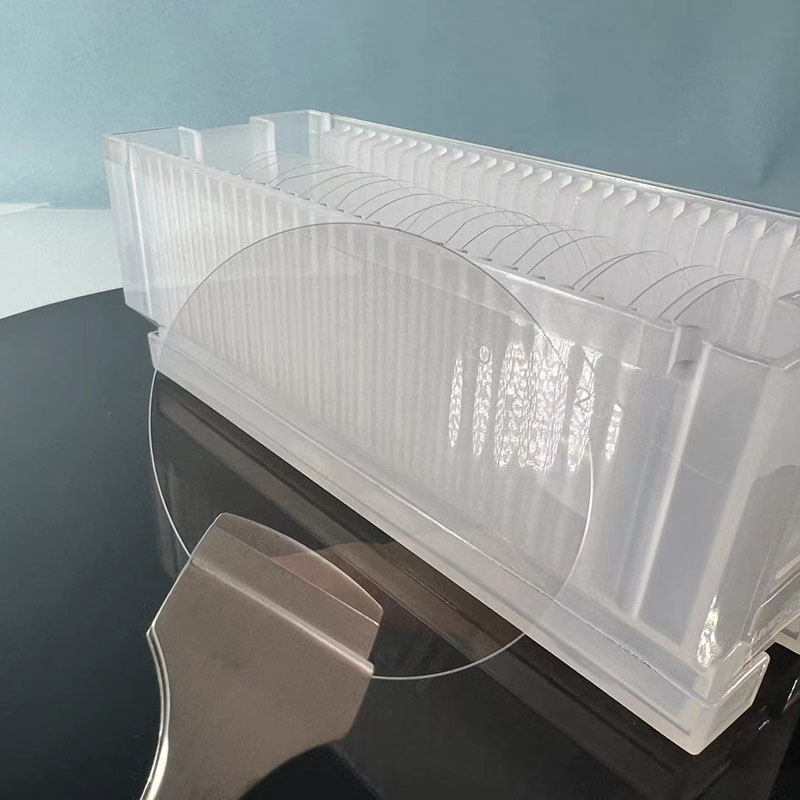

| Akụkụ (L × W × H) | 4000 x 3400 x 4300 mm ma ọ bụ hazie |

| Dayameta ụlọ ọkụ | 1100mm |

| Ikike ibu | 50kg |

| Oke oghere ogo | 10-2Pa (2h mgbe mgbapụta molekụla amalite) |

| Ọnụego ịrị elu nke ụlọ | ≤10Pa/h (mgbe calcination gasịrị) |

| Lower ọkụ cover ebuli ọrịa strok | 1500mm |

| Usoro kpo oku | Induction kpo oku |

| Okpomọkụ kachasị na ọkụ ọkụ | 2400°C |

| Ọkụ ọkụ ọkụ | 2X40kW |

| Nleta okpomọkụ | Ntụ okpomọkụ infrared agba abụọ |

| Oke okpomọkụ | 900 ~ 3000 ℃ |

| Izi ezi njikwa okpomọkụ | ±1°C |

| Oke nrụgide njikwa | 1 ~ 700mbar |

| Ịdị mma njikwa nrụgide | 1 ~ 5mbar ± 0.1mbar; 5 ~ 100mbar ± 0.2mbar; 100 ~ 700mbar ± 0.5mbar |

| Ụzọ ntinye | Ngwunye ala; |

| Nhazi nhọrọ | Ebe elele okpomọkụ okpukpu abụọ, na-ebutu forklift. |

Ọrụ XKH:

XKH na-enye ọrụ okirikiri zuru oke maka ọkụ ọkụ silicon carbide CVD, gụnyere nhazi akụrụngwa (mmepụta mpaghara okpomọkụ, nhazi sistemu gas), mmepe usoro (njikwa kristal, njikarịcha ntụpọ), ọzụzụ teknụzụ (ọrụ na mmezi) na nkwado azụmaahịa (akụkụ akụkụ mapụtara nke ihe ndị dị mkpa, nyocha dịpụrụ adịpụ) iji nyere ndị ahịa aka nweta oke nrụpụta SiC substrate uka mmepụta. Ma nyekwa ọrụ nkwalite usoro ka ọ na-aga n'ihu na-emewanye mkpụrụ kristal na nrụpụta uto.