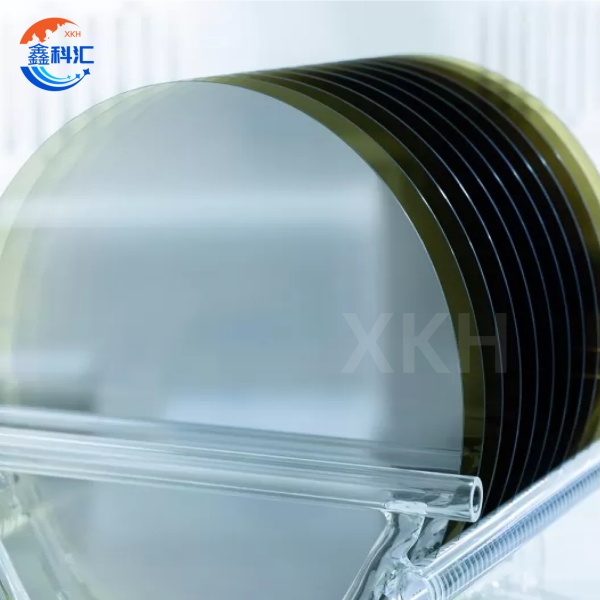

Ụdị SiC kristal ahaziri ahazi Dia 205/203/208 Ụdị 4H-N maka Nkwukọrịta Ngwa.

Usoro nka

Silicon carbide mkpụrụ wafer | |

Ụdị poly | 4H |

Njehie nhazi ihu elu | 4° chere ihu <11-20>±0.5º |

Nguzogide | nhazi |

Dayameta | 205 ± 0.5mm |

Ọkpụrụkpụ | 600± 50μm |

Isi ike | CMP, Ra≤0.2nm |

Njupụta Micropipe | ≤1 ea/cm2 |

Ọkpụkpụ | ≤5, ngụkọta ogologo≤2* dayameta |

Iberibe ibe/indents | Ọ dịghị |

Akara laser n'ihu | Ọ dịghị |

Ọkpụkpụ | ≤2, ngụkọta ogologo≤ Dayameta |

Iberibe ibe/indents | Ọ dịghị |

Mpaghara polytype | Ọ dịghị |

Akara laser azụ | 1mm (site na n'elu elu) |

Ọnụ | Chamfer |

Nkwakọ ngwaahịa | Multi-wafer cassette |

Njirimara isi

1. Crystal Structure na Electric Performance

· Crystallographic Stability: 100% 4H-SiC polytype dominance, zero multicrystalline inclusions (eg, 6H/15R), na XRD mkpatụ curve zuru-obosara na ọkara-kacha (FWHM) ≤32.7 arcsec.

· Mbugharị ụgbọ elu dị elu: Mbugharị eletrọn nke 5,400 cm²/V·s (4H-SiC) na oghere oghere nke 380 cm²/V·s, na-eme ka eserese ngwaọrụ dị elu.

Ike ike radieshon: Na-eguzogide 1 MeV neutron irradiation nwere oke mmebi nke 1 × 10¹⁵ n/cm², dị mma maka ikuku ikuku na ngwa nuklia.

2. Thermal na Mechanical Njirimara

· Omume okpomọkụ pụrụ iche: 4.9 W / cm · K (4H-SiC), okpukpu atọ nke silicon, na-akwado ọrụ n'elu 200 ° C.

Obere Mgbasa Mgbasa Ọkụ dị ala: CTE nke 4.0 × 10⁻⁶/K (25-1000°C), na-eme ka ndakọrịta na nkwakọ ngwaahịa silicon na ibelata nrụgide okpomọkụ.

3. Njikwa adịghị mma na nhazi nhazi

Njupụta Micropipe: <0.3 cm⁻² (wafers 8-inch), njupụta njupụta <1,000 cm⁻² (kwetara site na KOH etching).

Ọdịmma dị elu: CMP na-egbu maramara ka ọ bụrụ Ra <0.2 nm, na-ezute ihe achọrọ flatness nke EUV lithography.

Ngwa igodo

| ngalaba | Ihe ngosi ngwa | Uru nka |

| Communications Optical | 100G/400G lasers, silicon photonics ngwakọ modul | Mkpụrụ mkpụrụ InP na-eme ka bandgap kpọmkwem (1.34 eV) na heteroepitax nke dabeere na Si, na-ebelata mfu njikọ anya. |

| Ụgbọ ala ume ọhụrụ | 800V elu voltaji inverters, n'elu chaja (OBC) | Ihe ntinye 4H-SiC na-eguzogide> 1,200 V, na-ebelata mfu conduction site na 50% yana olu sistemụ site na 40%. |

| Mmekọrịta 5G | Ngwaọrụ RF Millimeter-wave (PA/LNA), ihe mgba ọkụ ọdụ ọdụ | Mgbochi SiC na-ekpuchi ọkara (resistivity> 10⁵ Ω·cm) na-eme ka mbanye na-agafe agafe ugboro dị elu (60 GHz+). |

| Akụrụngwa ụlọ ọrụ | Ihe mmetụta okpomọkụ dị elu, ihe ngbanwe dị ugbu a, ihe nleba anya ngwa ngwa nuklia | Mkpụrụ mkpụrụ inSb (0.17 eV bandgap) na-enye ikike ndọta ruo 300% @ 10 T. |

Uru ndị bụ isi

SiC (silicon carbide) mkpụrụ kristal mkpụrụ na-ebuga arụmọrụ na-enweghị atụ na 4.9 W / cm · K thermal conductivity, 2 – 4 MV / cm breakdown field ike, na 3.2 eV wide bandgap, na-eme ka ike dị elu, ugboro ugboro, na ngwa okpomọkụ dị elu. Na-egosipụta njupụta micropipe efu na <1,000 cm⁻² njupụta dislocation, ihe ndị a na-ahụ maka ntụkwasị obi na ọnọdụ dị oke egwu. Inertness kemịkalụ ha na elu CVD dakọtara (Ra <0.2 nm) na-akwado uto heteroepitaxial dị elu (dịka, SiC-on-Si) maka optoelectronics na sistemụ ike EV.

Ọrụ XKH:

1. Mmepụta ahaziri ahazi

Ụdị Wafer na-agbanwe agbanwe: 2-12-inch wafers nwere okirikiri, akụkụ anọ, ma ọ bụ nke nwere ụdị omenala (± 0.01 mm ndidi).

Njikwa doping: nitrogen (N) na aluminom (Al) doping nke ọma site na CVD, na-enweta ihe mgbochi sitere na 10⁻³ ruo 10⁶ Ω·cm.

2. Advanced Usoro Teknụzụnke

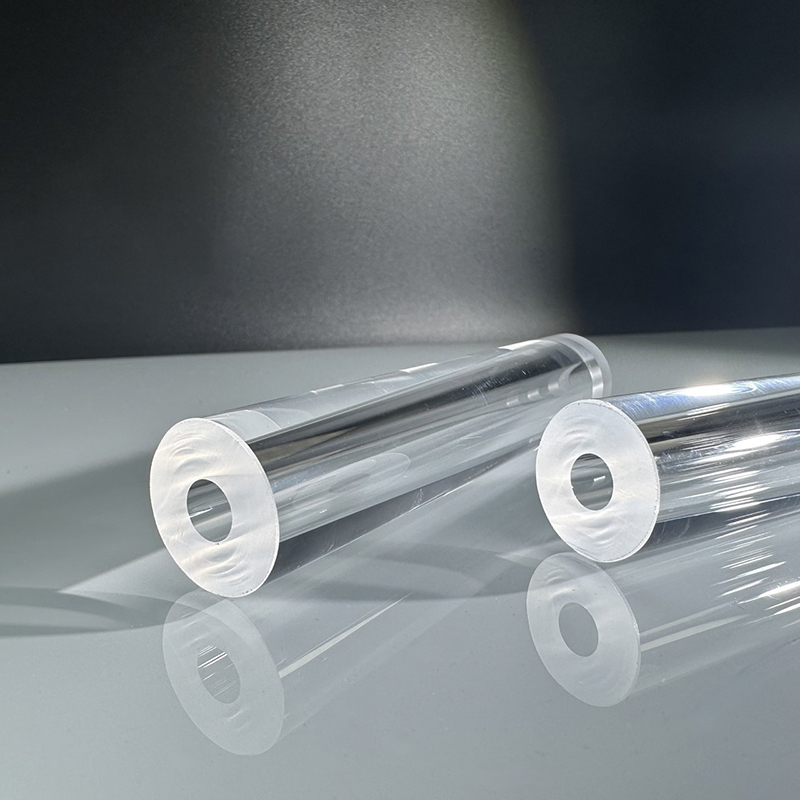

· Heteroepitaxy: SiC-on-Si (dakọtara na 8-inch silicon ahịrị) na SiC-on-Diamond (thermal conductivity>2,000 W / m·K).

Mbelata ntụpọ: hydrogen etching na annealing iji belata micropipe / njupụta ntụpọ, na-eme ka wafer mkpụrụ ruo>95%.

3. Quality Management Systemsnke

Nnwale ngwụcha ruo ngwụcha: Raman spectroscopy (nkwado polytype), XRD (crystallinity), na SEM (nyocha ntụpọ).

· Asambodo: Dabara na AEC-Q101 (ụgbọala), JEDEC (JEDEC-033), na MIL-PRF-38534 (ọkwa agha).

4. Nkwado Chain Supply Globalnke

· Ike mmepụta: mmepụta kwa ọnwa> 10,000 wafers (60% 8-inch), na nnyefe mberede 48-hour.

Network Logistics: Mkpuchi na Europe, North America, na Asia-Pacific site na ibu ikuku / oke osimiri na nkwakọ ngwaahịa na-achịkwa okpomọkụ.

5. Nkà na ụzụ Co-Developmentnke

Ụlọ nyocha R&D jikọrọ ọnụ: Imekọ ọnụ na njikarịcha nkwakọ ngwaahịa ike modul SiC (dịka ọmụmaatụ, ntinye mkpụrụ nke DBC).

Ikikere IP: Nye GaN-on-SiC RF ikike teknụzụ uto epitaxial iji belata ọnụ ahịa R&D ndị ahịa.

Nchịkọta

SiC (silicon carbide) mkpụrụ kristal mkpụrụ, dị ka ihe eji eme atụmatụ, na-emegharị ụdọ ụlọ ọrụ mmepụta ihe zuru ụwa ọnụ site na ọganiihu na uto kristal, njikwa ntụpọ, yana njikọta dị iche iche. Site n'ịga n'ihu na-aga n'ihu na mbelata ntụpọ wafer, na-emepụta mmepụta 8-inch, na ịgbasa ikpo okwu heteroepitaxial (dịka, SiC-on-Diamond), XKH na-ebuga ntụkwasị obi dị elu, ngwọta dị ọnụ ahịa maka optoelectronics, ike ọhụrụ, na mmepụta dị elu. Nkwenye anyị na imepụta ihe ọhụrụ na-eme ka ndị ahịa na-eduga na nnọpụiche carbon na sistemụ nwere ọgụgụ isi, na-ebuga oge na-esote nke gburugburu ebe obibi semiconductor obosara bandgap.