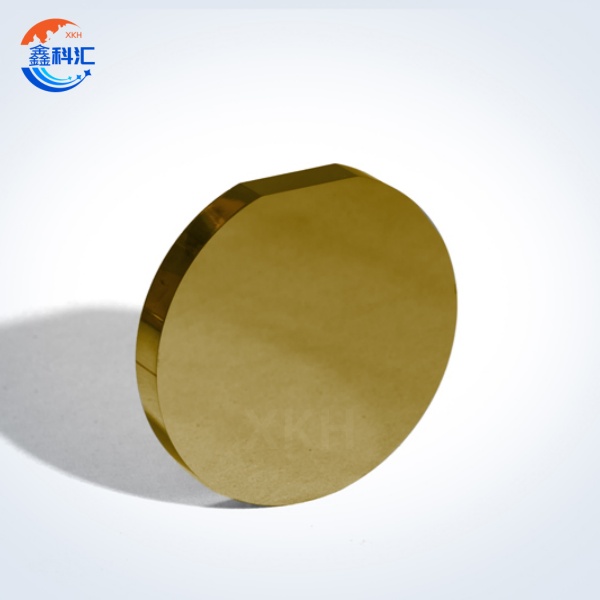

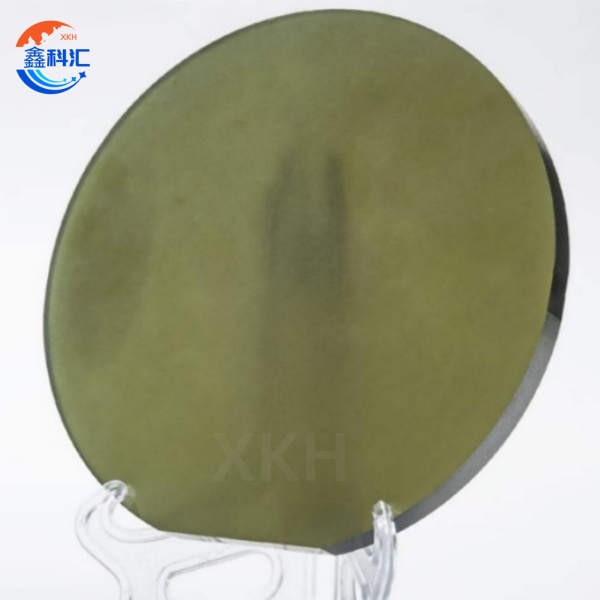

12 inch SiC mkpụrụ dayameta 300mm ọkpụrụkpụ 750μm 4H-N Ụdị nwere ike ahaziri

Usoro nka

| 12 inch Silicon Carbide (SiC) nkọwapụta mkpụrụ | |||||

| Ọkwa | Mmepụta ZeroMPD Ọkwa (ọkwa Z) | Standard mmepụta Ọkwa(P Ọkwa) | Ngụsị akwụkwọ (D ọkwa) | ||

| Dayameta | 3 00mm ~ 1305mm | ||||

| Ọkpụrụkpụ | 4H-N | 750μm± 15 μm | 750μm±25 μm | ||

| 4H-SI | 750μm± 15 μm | 750μm±25 μm | |||

| Usoro Wafer | Gbanyụọ axis: 4.0° n'ebe <1120>±0.5° maka 4H-N, On axis: <0001>±0.5° maka 4H-SI | ||||

| Njupụta Micropipe | 4H-N | ≤0.4cm-2 | ≤4cm-2 | ≤25cm-2 | |

| 4H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Nguzogide | 4H-N | 0.015 ~ 0.024 Ω·cm | 0.015 ~ 0.028 Ω·cm | ||

| 4H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Nhazi Flat nke izizi | {10-10} ±5.0° | ||||

| Ogologo Flat nke izizi | 4H-N | N/A | |||

| 4H-SI | Ọkwa | ||||

| Mwepu ihu | 3 mm | ||||

| LTV/TTV/Ụta/Warp | ≤5μm/≤15μm/≤35 μm/≤55 μm | ≤5μm/≤15μm/≤35 □ μm/≤55 □ μm | |||

| Isi ike | Polish Ra≤1 nm | ||||

| CMP Ra≤0.2 nm | Ra ≤0.5 nm | ||||

| Edge cracks Site na nnukwu ọkụ ọkụ Efere Hex Site na Ìhè Dị Elu Mpaghara Polytype Site n'ìhè dị elu Ntinye Carbon Anya Anya Silicon dị n'elu Scratches Site na nnukwu ọkụ ọkụ | Ọ dịghị Mpaghara mkpokọta ≤0.05% Ọ dịghị Mpaghara mkpokọta ≤0.05% Ọ dịghị | Ogologo ngụkọta ≤ 20 mm, otu ogologo≤2 mm Mpaghara mkpokọta ≤0.1% Mpaghara mkpokọta≤3% Mpaghara mkpokọta ≤3% Mgbakọ ogologo≤1 × dayameta wafer | |||

| Chips Edge Site na Ìhè Dị Elu | Ọnweghị nke anabatara obosara na omimi ≥0.2mm | 7 kwere, ≤1 mm nke ọ bụla | |||

| (TSD) Ịghasa eriri eriri | ≤500 cm-2 | N/A | |||

| (BPD) Ntugharị ụgbọ elu isi | ≤1000 cm-2 | N/A | |||

| Mmetọ Silicon dị n'elu site na ọkụ dị elu | Ọ dịghị | ||||

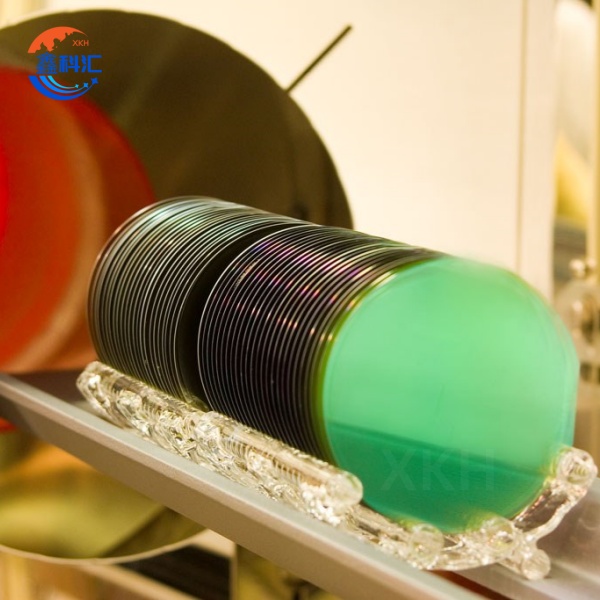

| Nkwakọ ngwaahịa | Cassette Multi-wafer ma ọ bụ otu akpa wafer | ||||

| ndetu: | |||||

| 1 Oke ntụpọ na-emetụta n'elu wafer dum belụsọ mpaghara mwepu ihu. 2Ekwesịrị ịlele ncha ahụ naanị na ihu Si. 3 Data mwepu bụ naanị site na KOH etched wafers. | |||||

Atụmatụ igodo

1.Production ike na uru bara uru: mmepụta ihe dị ukwuu nke 12-inch SiC substrate (12-inch silicon carbide substrate) na-egosi oge ọhụrụ na mmepụta semiconductor. Ọnụọgụ ibe ibe a na-enweta site na otu wafer ruru ugboro 2.25 karịa nke anụ ọhịa 8, na-ebute mmụba ozugbo na nrụpụta nrụpụta. Nzaghachi nke ndị ahịa na-egosi na ịnakwere mkpụrụ 12-inch ebelatala ọnụ ahịa mmepụta modul ike ha site na 28%, na-ekepụta uru asọmpi dị mkpa n'ahịa a na-asọ mpi.

2.Outstanding Physical Properties: The 12-inch SiC substrate eketa niile uru nke silicon carbide ihe - ya thermal conductivity bụ 3 ugboro nke silicon, mgbe ya mmebi ubi ike ruru 10 ugboro nke silicon. Njirimara ndị a na-enyere ngwaọrụ ndị dabere na ihe ndị dị inch 12 ka ọ rụọ ọrụ nke ọma na gburugburu okpomọkụ dị elu karịa 200 Celsius, na-eme ka ha dabara adaba maka ngwa ndị na-achọsi ike dị ka ụgbọ ala eletrik.

3.Surface Treatment Technology: Anyị na-emepụta a akwụkwọ akụkọ chemical mechanical polishing (CMP) usoro kpọmkwem maka 12-inch SiC substrates, ọbọ atomic-larịị elu flatness (Ra <0.15nm). Ọganihu a na-edozi ihe ịma aka zuru ụwa ọnụ nke nnukwu ọgwụgwọ silicon carbide wafer elu, na-ekpochapụ ihe mgbochi maka uto epitaxial dị elu.

4.Thermal Management Performance: Na ngwa bara uru, 12-inch SiC substrates na-egosipụta ike ikpochapụ okpomọkụ dị ịrịba ama. Data ule na-egosi na n'okpuru otu ike njupụta, ngwaọrụ na-eji 12-inch substrates na-arụ ọrụ na okpomọkụ 40-50 Celsius ala karịa silicon dabeere na ngwaọrụ, nke ukwuu ịgbatị ngwa ọrụ ndụ ọrụ.

Ngwa isi

1.New Energy Vehicle Ecosystem: The 12-inch SiC substrate (12-inch silicon carbide substrate) na-agbanwegharị ihe owuwu ụgbọ ala eletrik. Site na chaja onboard (OBC) ruo na ndị na-atụgharị draịva na sistemu njikwa batrị, mmezi arụmọrụ nke ihe ntanetị inch 12 wetara na-abawanye oke ụgbọ site na 5-8%. Akụkọ sitere na ndị na-emepụta ụgbọ ala na-egosi na ịnakwere ihe ndị dị inch 12 anyị belatara ọnwụ ike na sistemụ chaja ngwa ngwa ha site na nnukwu 62%.

2.Renewable Energy Sector: Na fotovoltaic ike ọdụ, inverters dabeere na 12-inch SiC substrates ọ bụghị nanị na-egosipụta obere ụdị ihe ma nwetakwa ntughari arụmọrụ karịrị 99%. Karịsịa na ndapụta ọgbọ nke kesara, arụmọrụ dị elu a na-atụgharị na nchekwa kwa afọ nke narị puku yuan na mfu ọkụ eletrik maka ndị ọrụ.

3.Industrial Automation: Ndị na-emegharị ugboro ugboro na-eji ihe ntanetị 12-inch na-egosi arụmọrụ dị mma na robots mmepụta ihe, ngwá ọrụ CNC igwe, na ngwá ọrụ ndị ọzọ. Àgwà ngbanwe ha dị elu na-eme ka ọsọ nzaghachi moto dị 30% na-ebelata nnyonye anya electromagnetic gaa na otu ụzọ n'ụzọ atọ nke ngwọta nkịtị.

4.Consumer Electronics Innovation: Teknụzụ na-ebu ngwa ngwa smartphone nke na-abịa n'ihu amalitela ịnakwere 12-inch SiC substrates. A na-atụ anya na ngwaahịa na-ebu ngwa ngwa karịa 65W ga-agbanwe kpamkpam na ngwọta silicon carbide, yana ihe ntanetị 12-inch na-apụta dị ka nhọrọ kacha mma.

Ọrụ ahaziri XKH maka 12-inch SiC Substrate

Iji mezuo ihe achọrọ maka 12-inch SiC substrates (12-inch silicon carbide substrates), XKH na-enye nkwado ọrụ zuru oke:

1.thickness customization:

Anyị na-enye 12-inch substrates dị iche iche ọkpụrụkpụ nkọwa gụnyere 725μm izute dị iche iche ngwa mkpa.

2. Doping itinye uche:

Nrụpụta anyị na-akwado ọtụtụ ụdị conductivity gụnyere ụdị n-ụdị na p-ụdị substrates, yana njikwa mgbochi ziri ezi na oke 0.01-0.02Ω · cm.

3. Ọrụ nnwale:

Site na ngwa nyocha ọkwa wafer zuru oke, anyị na-enye akụkọ nyocha zuru oke.

XKH ghọtara na onye ahịa ọ bụla nwere ihe pụrụ iche chọrọ maka 12-inch SiC substrates. Ya mere, anyị na-enye ụdị imekọ ihe ọnụ azụmaahịa na-agbanwe agbanwe iji nye azịza kachasị asọmpi, ma maka:

· Ihe atụ R&D

· Ịzụta mmepụta olu

Ọrụ ahaziri ahazi anyị na-ahụ na anyị nwere ike gboo mkpa teknụzụ na mmepụta gị maka ihe ntinye 12-inch nke SiC.