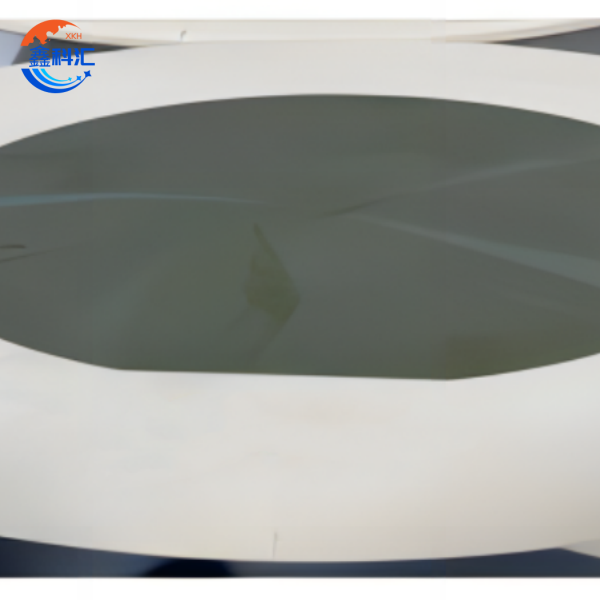

Ngwa wafer dị nro maka 4 inch-12 inch sapphire/SiC/Si Wafers nhazi

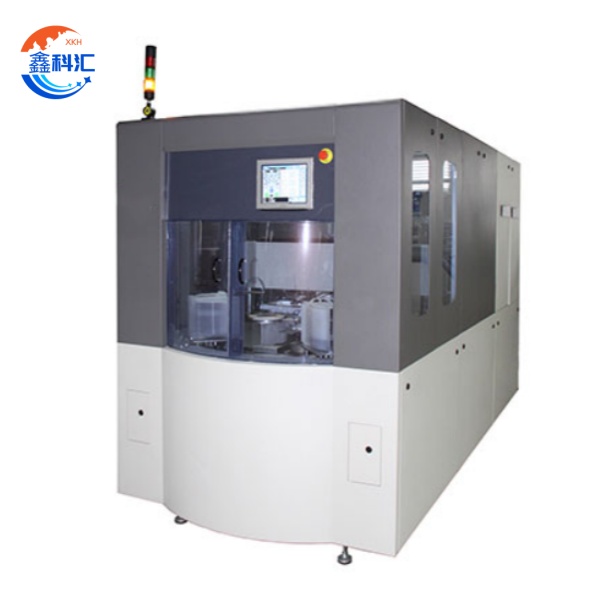

Ụkpụrụ ọrụ

Usoro thinning wafer na-arụ ọrụ site na nkebi atọ:

Na-egweri siri ike: Wheel diamond (grit size 200-500 μm) na-ewepụ 50-150 μm nke ihe na 3000-5000 rpm iji belata oke ibu ngwa ngwa.

Echicha dị mma: wheel dị mma (grit size 1-50 μm) na-ebelata oke ruo 20-50 μm na <1 μm/s iji belata mmebi nke ala.

Polishing (CMP): Igwe mmiri na-arụ ọrụ kemịkalụ na-ewepụ mmebi fọdụrụnụ, na-enweta Ra <0.1 nm.

Ngwa dakọtara

Silicon (Si): Ọkọlọtọ maka CMOS wafers, gbadara ruo 25 μm maka nchịkọta 3D.

Silicon Carbide (SiC): chọrọ wiil diamond pụrụ iche (80% ntinye diamond) maka nkwụsi ike ọkụ.

Sapphire (Al₂O₃): Tọrọ ruo 50 μm maka ngwa UV LED.

Ngwa Sistemụ Isi

1. Sistemụ egweri

Igwe ihe igwe abuo-Axis: Na-ejikọta nke ọma / nke ọma n'otu ikpo okwu, na-ebelata oge okirikiri site na 40%.

Spindle Aerostatic: 0-6000 rpm ọsọ ọsọ yana <0.5 μm radial runout.

2. Sistemụ njikwa Wafer

Vacuum Chuck:> 50 N na-ejide ike na ± 0.1 μm nguzozi ziri ezi.

Arm Robotic: Na-ebufe wafers 4-12-inch na 100 mm/s.

3. Sistemụ njikwa

Interferometry Laser: Nleba anya ọkpụrụkpụ oge (mkpebi 0.01 μm).

Feedforward AI-chụpụrụ: na-ebu amụma iyi wiil ma na-ahazi paramita na-akpaghị aka.

4. Ịjụ oyi & Nhicha

Nchacha Ultrasonic: na-ewepụ irighiri ihe> 0.5 μm na arụmọrụ 99.9%.

Mmiri Deionized: Na-eme ka wafer dị jụụ ruo <5°C n'elu ambient.

Isi Uru

1. Ultra-High Precision: TTV (Mkpokọta Ọdịmma Ọdịmma) <0.5 μm, WTW (N'ime-Ọdịmma Ọdịmma n'ime Wafer) <1 μm.

2. Multi-Process Integration: Na-ejikọta egweri, CMP, na plasma etching na otu igwe.

3. Ndakọrịta ihe:

Silicon: Mbelata ịdị arọ site na 775 μm ruo 25 μm.

SiC: Na-enweta <2 μm TTV maka ngwa RF.

Doped Wafers: Phosphorus-doped InP wafers nwere <5% drift resistivity.

4. Smart Automation: MES mwekota na-ebelata njehie mmadụ site na 70%.

5. Ịrụ ọrụ ike: 30% ike dị ala site na breeki nrụpụta.

Ngwa igodo

1. Nkwakọ ngwaahịa dị elu

• 3D ICs: Wafer thinning na-enyere aka stacking vetikal nke mgbagha / ebe nchekwa ibe (dịka, HBM stacks), nweta 10 × elu bandwit na 50% belatara ike oriri ma e jiri ya tụnyere 2.5D ngwọta. Akụrụngwa na-akwado njikọta ngwakọ na njikọta TSV (Site na Silicon Via), dị oke mkpa maka ndị nrụpụta AI / ML chọrọ <10 μm interconnect pitch. Ọmụmaatụ, 12-inch wafers thinned ka 25 μm na-enye ohere stacking 8+ n'ígwé na-ejigide <1.5% warpage, dị mkpa maka ụgbọ ala LiDAR sistemụ.

• Nkwakọ ngwaahịa na-apụ apụ: Site na ibelata ọkpụrụkpụ wafer gaa na 30 μm, ogologo njikọ na-ebelata site na 50%, na-ebelata oge mgbaama (<0.2 ps/mm) ma na-enye 0.4 mm chiplets ultra-thin maka mobile SoCs. Usoro a na-eme ka algọridim na-egweri ụgwọ nrụgide iji gbochie warpage (> 50 μm TTV njikwa), na-eme ka ntụkwasị obi na ngwa RF dị elu.

2. Igwe ọkụ eletrik

• Modules IGBT: Ịdị nro na 50 μm na-ebelata nkwụsị okpomọkụ na <0.5 ° C / W, na-eme ka 1200V SiC MOSFET rụọ ọrụ na 200 ° C nkwụsị okpomọkụ. Akụrụngwa anyị na-eji igwe igwe dị iche iche (nke siri ike: 46 μm grit → mma: 4 μm grit) iji kpochapụ mmebi nke ala, na-enweta> 10,000 cycles nke ntụkwasị obi ịgba ígwè. Nke a dị oke mkpa maka ndị ntụgharị EV, ebe 10 μm-oke SiC wafers na-eme ka ọsọ ngbanwe site na 30%.

• Ngwa ike GaN-on-SiC: Wafer thinning na 80 μm na-eme ka mmegharị eletrọn (μ> 2000 cm² / V·s) maka 650V GaN HEMTs, na-ebelata ihe nhụsianya nke 18%. Usoro a na-eji dicing na-enyere laser aka igbochi mgbawa n'oge mkpa, na-enweta <5 μm ihu chipping maka RF ike amplifiers.

3. Optoelectronics

• GaN-on-SiC LEDs: 50 μm sapphire substrates na-eme ka ọrụ mmịpụta ìhè dịkwuo mma (LEE) ruo 85% (vs. 65% maka 150 μm wafers) site na ibelata ọnyà foton. Njikwa TTV dị ala dị ala nke akụrụngwa anyị (<0.3 μm) na-eme ka ọ pụta ìhè n'otu n'otu n'ofe wafer 12-inch, dị oke mkpa maka ngosipụta Micro-LED chọrọ ịdị n'otu n'ogologo 100nm.

• Silicon Photonics: 25μm-thick silicon wafers na-enyere 3 dB / cm obere mgbasa mgbasa na-efegharị efegharị, dị mkpa maka 1.6 Tbps transceivers optical. Usoro a na-ejikọta CMP smoothing iji belata nhụsianya elu na Ra <0.1 nm, na-eme ka nrụpụta njikọ dị mma site na 40%.

4. Ihe mmetụta MEMS

• Accelerometers: 25 μm silicon wafers na-enweta SNR> 85 dB (vs. 75 dB maka 50 μm wafers) site n'ịbawanye mmetụta mgbapụ ihe akaebe. Sistemụ egweri axis abụọ anyị na-akwụ ụgwọ maka gradients nrụgide, na-eme ka <0.5% nwee mmetụta uche na-agafe -40°C ruo 125°C. Ngwa gụnyere nchọpụta okuku ụgbọ ala yana nsochi ngagharị AR/VR.

• Sensọ nrụgide: Ịba ruo 40 μm na-enyere 0-300 mmanya aka nha nha na <0.1% FS hysteresis. N'iji njikọta nwa oge (ndị na-ebu iko), usoro a na-ezere mgbaji wafer n'oge etching azụ, na-enweta <1 μm overpressure ndidi maka sensọ IoT ụlọ ọrụ.

• Mmekọrịta nka na ụzụ: Ngwá ọrụ na-akpụ akpụ anyị na-eme ka egwe igwe dị n'otu, CMP, na plasma etching iji dozie ihe ịma aka dị iche iche (Si, SiC, Sapphire). Dị ka ọmụmaatụ, GaN-on-SiC chọrọ ngwakọ egweri (wheel diamond + plasma) iji dozie ike na mgbasawanye ọkụ, ebe ihe mmetụta MEMS na-achọ sub-5 nm n'elu ala site na polishing CMP.

• Mmetụta ụlọ ọrụ: Site n'ime ka ndị na-esi ísì ụtọ, ndị na-arụ ọrụ dị elu, nkà na ụzụ a na-eme ka ihe ọhụrụ dị na AI chips, 5G mmWave modules, na ngwá electronic na-agbanwe agbanwe, na TTV tolerances <0.1 μm maka ngosi foldable na <0.5 μm maka ihe mmetụta LiDAR ụgbọ ala.

Ọrụ XKH

1. Ngwọta ahaziri ahazi

Nhazi nhazi: 4-12-inch chamber designs with loading/butu akpaaka.

Nkwado Doping: Ezi ntụziaka maka kristal Er/Yb-doped na wafers InP/GaAs.

2. Nkwado ngwụcha ruo ngwụcha

Mmepe usoro: Ọnwụnwa efu na-eji njikarịcha.

Ọzụzụ zuru ụwa ọnụ: Ụlọ ọrụ nka nka kwa afọ maka nrụzi na nchọpụta nsogbu.

3. Nhazi Multi-Material

SiC: Wafer thinning ruo 100 μm na Ra <0.1 nm.

Sapphire: ọkpụrụkpụ 50μm maka windo laser UV (nfe> 92% @ 200 nm).

4. Ọrụ agbakwunyere uru

Ihe oriri: wiil diamond (2000+ wafers / ndụ) na CMP slurries.

Mmechi

Ngwá ọrụ a na-eme ka ọ dị nro na-ebuga nkenke nke ụlọ ọrụ na-eduzi, ọtụtụ ihe dị iche iche, na automation smart, na-eme ka ọ dị mkpa maka ntinye 3D na ngwá electronic. Ọrụ zuru oke nke XKH - site na nhazi ya ruo nhazi nhazi - hụ na ndị ahịa nweta arụmọrụ ọnụ ahịa na arụmọrụ kachasị mma na mmepụta semiconductor.