Silicon carbide seramiiki tray sucker Silicon carbide seramiiki tube na-enye nhazi nhazi omenala dị elu nke okpomọkụ.

Isi atụmatụ:

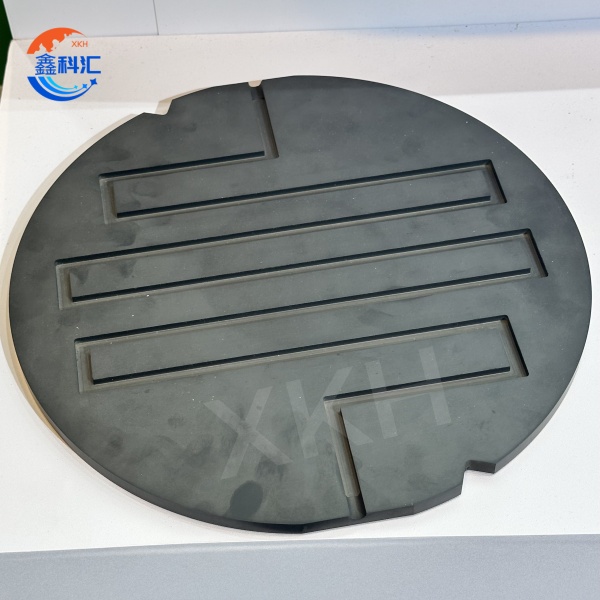

1. Silicon carbide seramiiki tray

- Ike siri ike ma na-eyi nguzogide: ike siri ike dị nso na diamond, ma nwee ike iguzogide ihe eji arụ ọrụ na nhazi wafer ruo ogologo oge.

- Igwe ọkụ ọkụ dị elu na ọnụọgụ mgbasawanye ọkụ dị ala: nkwụsị ọkụ ngwa ngwa na nkwụsi ike nke akụkụ, na-ezere nrụrụ nke nrụgide okpomọkụ kpatara.

- Elu dị elu na imecha elu: elu elu dị elu ruo ọkwa micron, na-eme ka kọntaktị zuru oke n'etiti wafer na diski, na-ebelata mmetọ na mmebi.

Nkwụsi ike nke kemịkalụ: Nguzogide corrosion siri ike, dabara maka nhicha mmiri na usoro etching na nrụpụta semiconductor.

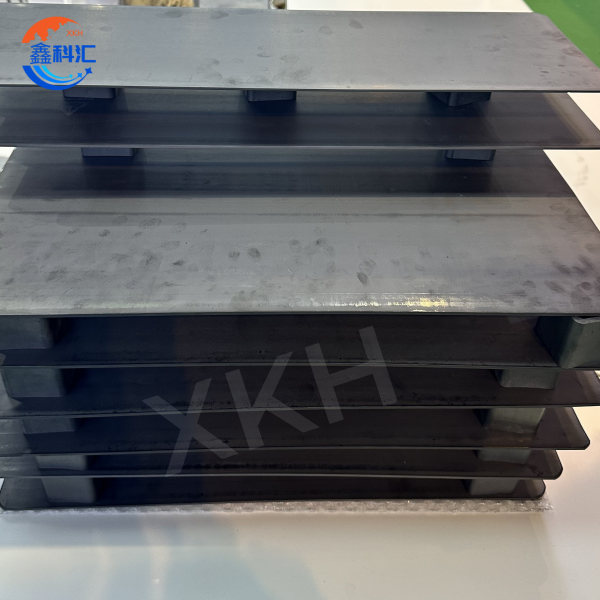

2. Silicon carbide seramiiki tube

- Igwe ọkụ dị elu: Ọ nwere ike ịrụ ọrụ na gburugburu ebe okpomọkụ dị elu karịa 1600 ° C ruo ogologo oge, dabara maka usoro okpomọkụ dị elu nke semiconductor.

Nguzogide corrosion mara mma: na-eguzogide acids, alkalis na ụdị ihe mgbaze kemịkalụ dị iche iche, dabara maka gburugburu usoro siri ike.

- High ike na eyi iguzogide: guzogide urughuru ozize na n'ibu eyi, ịgbatị ndụ ọrụ.

- Igwe ọkụ dị elu na ọnụ ọgụgụ dị ala nke mgbasawanye okpomọkụ: ngwa ngwa na-eduzi okpomọkụ na nkwụsi ike akụkụ, ibelata nrụrụ ma ọ bụ mgbawa nke nrụgide okpomọkụ kpatara.

Oke ngwaahịa:

Silicon carbide seramiiki tray paramita:

| (Ihe onwunwe) | (Nkeji) | (sic) | |

| (Ọdịnaya SiC) | (Wt)% | >99 | |

| (Ọkara nha ọka) | micron | 4-10 | |

| (Njupụta) | n'arọ/dm3 | > 3.14 | |

| (Porosity pụtara ìhè) | Vo1% | <0.5 | |

| (ike siri ike nke Vickers) | HV 0.5 | GPA | 28 |

| *() Ike mgbanwe* (isi atọ) | 20ºC | MPa | 450 |

| (ike mkpakọ) | 20ºC | MPa | 3900 |

| (Modulus Elastic) | 20ºC | GPA | 420 |

| (Ike mgbaji) | MPa/m'% | 3.5 | |

| (Thermal conductivity) | 20ºC | W/(m*K) | 160 |

| (Nguzogide) | 20ºC | Ohm.cm | 106-108 |

(Ntụkọba mgbasawanye thermal) | a (RT**...80ºC) | K-1*10-6 | 4.3 |

(Okpomọkụ kachasị arụ ọrụ) | oºC | 1700 | |

Silicon carbide ceramic tube paramita:

| Ihe | Index |

| α-SIC | 99% nkeji |

| Porosity pụtara | 16% kacha |

| Njupụta nnukwu | 2.7g/cm 3 nkeji |

| Na-ehulata ike na oke okpomọkụ | 100 Mpa min |

| Ọnụọgụ nke Thermal Mgbasawanye | K-1 4.7x10 -6 |

| Ọnụọgụ nke Thermal Conductivity (1400ºC) | 24 W/mk |

| Oke. Okpomọkụ na-arụ ọrụ | 1650ºC |

Ngwa ngwa:

1. Silicon carbide seramiiki efere

- Wafer ịkpụ na polishing: na-eje ozi dị ka ikpo okwu na-ebugharị iji hụ na nkwụsi ike dị elu na nkwụsi ike n'oge ịkpụ na polishing.

- Usoro lithography: A na-edozi wafer na igwe lithography iji hụ na a na-edobe oke n'oge mkpughe.

- Chemical Mechanical Polishing (CMP): na-arụ ọrụ dị ka ikpo okwu nkwado maka polishing pads, na-enye nrụgide otu na nkesa okpomọkụ.

2. Silicon carbide seramiiki tube

- Igwe ọkụ ọkụ dị elu: ejiri ya maka akụrụngwa okpomọkụ dị elu dị ka ọkụ mgbasa ozi na ọkụ oxidation na-ebu wafers maka ọgwụgwọ usoro okpomọkụ dị elu.

- CVD / PVD usoro: Dị ka tube na-ebu n'ime ụlọ mmeghachi omume, na-eguzogide okpomọkụ dị elu na gas na-emebi emebi.

- Ngwa ihe eji arụ ọrụ Semiconductor: maka ndị na-agbanwe ọkụ, pipeline gas, wdg, iji meziwanye njikwa njikwa ọkụ nke akụrụngwa.

XKH na-enye ọrụ omenala zuru oke maka trays seramiiki silicon carbide, iko mmiri ara na tubes seramiiki silicon carbide. Silicon carbide seramiiki trays na iko mmiri, XKH nwere ike ahaziri dị ka ndị ahịa chọrọ nke nha dị iche iche, ụdị na ịdị njọ nke elu, na-akwado ọgwụgwọ mkpuchi pụrụ iche, welie mkpuchi mkpuchi na mgbochi corrosion; Maka silicon carbide seramiiki tubes, XKH nwere ike hazie ụdị dị iche iche nke dayameta dị n'ime, dayameta dị n'èzí, ogologo na usoro mgbagwoju anya (dịka tube a na-emepụta ma ọ bụ tube porous), ma na-enye polishing, mkpuchi mgbochi oxidation na usoro ọgwụgwọ ndị ọzọ. XKH na-eme ka ndị ahịa nwee ike iji uru arụmọrụ nke ngwaahịa seramiiki silicon carbide iji mezuo ihe ndị a chọrọ nke ubi mmepụta ihe dị elu dị ka semiconductor, leds na fotovoltaics.

Eserese zuru ezu