SiCOI wafer 4inch 6inch HPSI SiC SiO2 Si subbatrate Ọdịdị

Ọdịdị SiCOI wafer

HPB (High-Performance Bonding) BIC (Bonded Integrated Circuit) na SOD (Silicon-on-Diamond ma ọ bụ Silicon-on-Insulator-like technology). Ọ gụnyere:

Usoro arụmọrụ:

Na-edepụta paramita dị ka izi ezi, ụdị njehie (dịka ọmụmaatụ, "Enweghị njehie," "Ebe dị ọnụ ahịa"), na nha nha (dịka ọmụmaatụ, "ọkpụrụkpụ-n'ikuku kpọmkwem/kg").

Tebụlụ nwere ụkpụrụ ọnụọgụ (ikekwe nnwale ma ọ bụ usoro usoro) n'okpuru isiokwu dịka "ADDR/SYGBDT," "10/0," wdg.

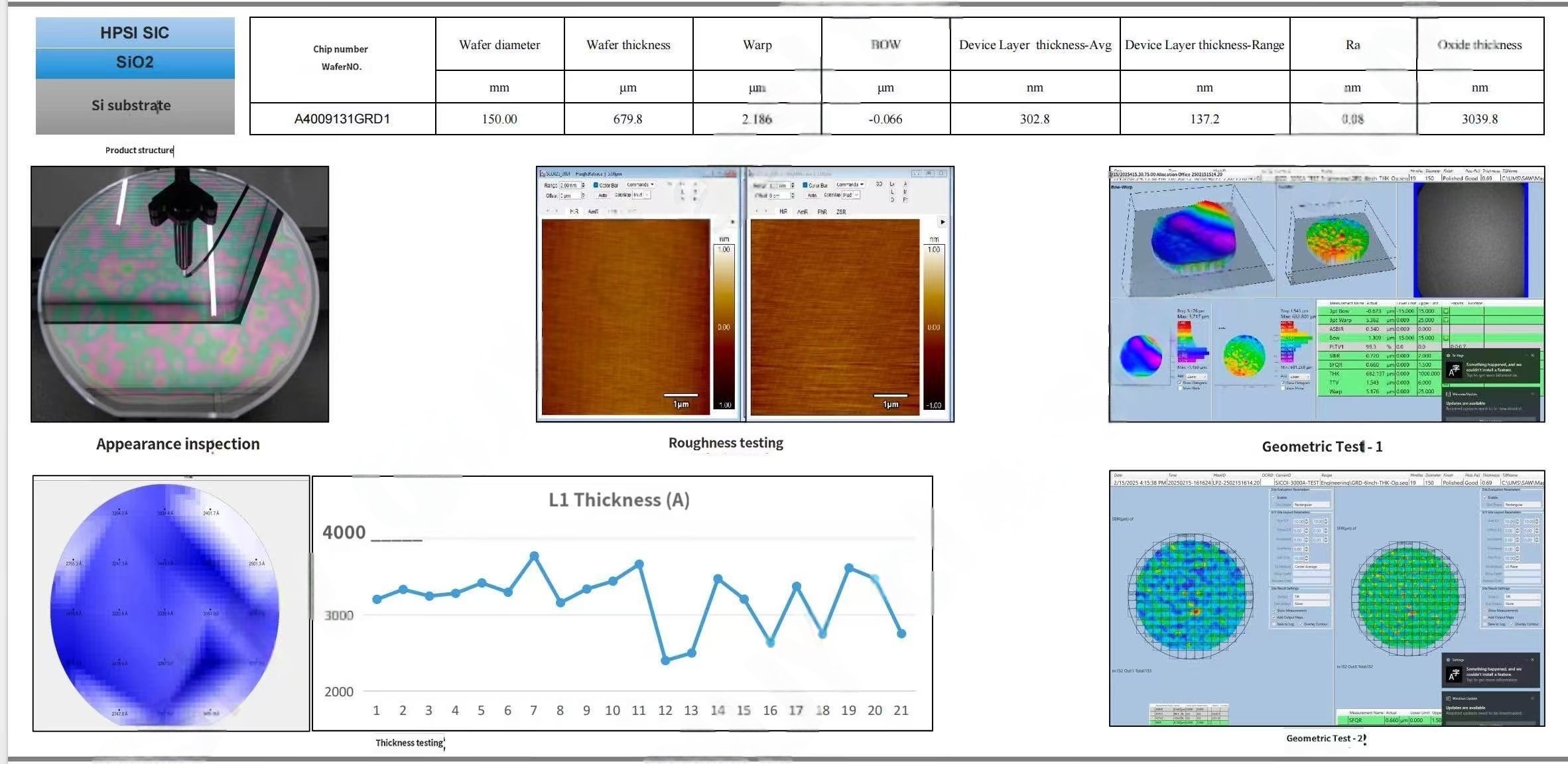

Data ọkpụrụkpụ oyi akwa:

Ndenye ugboro ugboro nke akpọrọ "Ọkpụrụkpụ L1 (A)" ruo "Ọkpụrụkpụ L270 (A)" (ikekwe na Ångströms, 1 Å = 0.1 nm).

Na-atụ aro ihe owuwu nwere ọtụtụ ihe nwere njikwa oke nha maka oyi akwa ọ bụla, nke a na-ahụkarị na wafers semiconductor dị elu.

Ọdịdị SiCOI Wafer

SiCOI (Silicon Carbide na Insulator) bụ ihe owuwu wafer pụrụ iche na-ejikọta silicon carbide (SiC) na mkpuchi mkpuchi, nke yiri SOI (Silicon-on-Insulator) mana emebere ya maka ngwa ike dị elu / oke ọkụ. Atụmatụ ndị bụ isi:

Nhazi oyi akwa:

N'elu oyi akwa: Silicon Carbide otu-kristal (SiC) maka ngagharị elektrọn dị elu na nkwụsi ike ọkụ.

Insulator liri: A na-ahụkarị SiO₂ (oxide) ma ọ bụ diamond (na SOD) iji belata ike nje ma melite ikewapụ.

Mkpụrụ ala: Silicon ma ọ bụ polycrystalline SiC maka nkwado igwe

Njirimara SiCOI wafer

Ngwongwo eletriki Wide Bandgap (3.2 eV maka 4H-SiC): Na-eme ka voltaji ndakpọ dị elu (> 10 × dị elu karịa silicon) .Na-ebelata mmiri iyi, na-eme ka arụmọrụ dị na ngwaọrụ ike.

Mbugharị Elektrọn dị elu:~ 900 cm²/V·s (4H-SiC) vs. ~ 1,400 cm²/V·s (Si), mana arụmọrụ dị elu ka mma.

Nguzogide dị ala:transistors dabere na SiCOI (dịka ọmụmaatụ, MOSFETs) na-egosipụta mfu ihe omume dị ala.

Ihe mkpuchi mara mma:Oxide e liri (SiO₂) ma ọ bụ oyi akwa diamond na-ebelata ikike parasitic na crosstalk.

- Njirimara okpomọkụIgwe ọkụ dị elu: SiC (~ 490 W / m · K maka 4H-SiC) vs. Si (~ 150 W / m·K) .Diamond (ma ọ bụrụ na ejiri ya dị ka insulator) nwere ike gafere 2,000 W / m · K, na-eme ka ikpo ọkụ na-ekpo ọkụ.

Nkwụsi ike okpomọkụ:Na-arụ ọrụ ntụkwasị obi na> 300°C (vs. ~ 150°C maka silicon) .Na-ebelata ihe jụrụ oyi na ngwa eletrọnịkị.

3. Mechanical & Chemical NjirimaraIke siri ike (~ 9.5 Mohs): na-eguzogide iyi, na-eme ka SiCOI na-adịgide adịgide maka gburugburu ebe dị njọ.

Ike kemịkalụ:Na-eguzogide oxidation na corrosion, ọbụna na ọnọdụ acidic/alkaline.

Mgbasawanye okpomọkụ dị ala:Dakọtara nke ọma na ihe ndị ọzọ dị elu (dịka, GaN).

4. Uru Nhazi (vs. Bulk SiC ma ọ bụ SOI)

Mfu mkpụrụ osisi belatara:Igwe mkpuchi mkpuchi na-egbochi ntapu ugbu a n'ime mkpụrụ.

Arụmọrụ RF emelitere:Obere ikike parasitic na-enyere aka ịgbanwe ngwa ngwa (bara uru maka ngwaọrụ 5G/mmWave).

Nhazi agbanwe agbanwe:oyi akwa SiC dị gịrịgịrị na-enye ohere maka ịchacha ngwaọrụ (dịka ọmụmaatụ, ọwa dị mkpa na transistor).

Tụnyere SOI & nnukwu SiC

| Ngwongwo | SiCOI | SOI (Si/SiO₂/Si) | nnukwu SiC |

| Bandgap | 3.2 eV (SiC) | 1.1 eV (Si) | 3.2 eV (SiC) |

| Nrụpụta okpomọkụ | Elu (SiC + diamond) | Obere (SiO₂ na-amachi oke ọkụ) | Elu (naanị SiC) |

| Voltaji ndakpọ | Dị Elu | Na-agafeghị oke | Dị Elu |

| Ọnụ | Nke ka elu | Ala | Kachasị elu (SiC dị ọcha) |

Ngwa SiCOI wafer

Igwe ọkụ eletrik

A na-eji wafer SiCOI eme ihe na ngwaọrụ semiconductor dị elu na ike dị elu dị ka MOSFETs, Schottky diodes, na ọkụ ọkụ. Bandgap sara mbara na voltaji ndakpọ dị elu nke SiC na-eme ka ntụgharị ike rụọ ọrụ nke ọma yana mbelata mfu yana nkwalite arụmọrụ ọkụ.

Ngwaọrụ ugboro redio (RF).

Igwe mkpuchi mkpuchi na SiCOI wafers na-ebelata ikike parasitic, na-eme ka ha dabara maka transistor ugboro dị elu na amplifiers ejiri na nkwukọrịta, radar, na teknụzụ 5G.

Sistemụ Microelectromechanical (MEMS)

SiCOI wafers na-enye ikpo okwu siri ike maka imepụta sensọ MEMS na ndị na-eme ihe na-arụ ọrụ ntụkwasị obi na gburugburu ebe siri ike n'ihi ike kemịkalụ SiC na ike arụ ọrụ.

Igwe eletrọnịkị dị elu

SiCOI na-enyere ngwá electronic na-ejigide arụmọrụ na ntụkwasị obi na okpomọkụ dị elu, na-erite uru ụgbọ ala, ikuku ikuku, na ngwa ụlọ ọrụ ebe ngwaọrụ silicon nkịtị na-ada.

Ngwa Photonic na Optoelectronic

Nchikota nke ngwa anya nke SiC na oyi akwa mkpuchi na-eme ka njikọta nke sekit photonic na njikwa ọkụ emelitere.

Igwe ọkụ ọkụ radieshọn-ike

N'ihi nnabata radieshon sitere na SiC, SiCOI wafers dị mma maka oghere na ngwa nuklia chọrọ ngwaọrụ ndị na-eguzogide gburugburu ebe ọkụ ọkụ.

Ajụjụ&A nke SiCOI wafer

Q1: Gịnị bụ SiCOI wafer?

A: SiCOI na-anọchi anya Silicon Carbide-on-Insulator. Ọ bụ ihe nrụpụta semiconductor ebe a na-ejikọ obere silicon carbide (SiC) na oyi akwa mkpuchi (na-abụkarị silicon dioxide, SiO₂), nke mkpụrụ silicon na-akwado. Ihe owuwu a na-ejikọta ihe ndị dị mma nke SiC na ikewapụ eletrik site na insulator.

Q2: Gịnị bụ isi uru nke SiCOI wafers?

A: Uru ndị bụ isi gụnyere voltaji ndakpọ dị elu, bandgap sara mbara, conductivity thermal magburu onwe ya, ike ọrụ dị elu, yana ike mbelata parasitic n'ihi oyi akwa mkpuchi. Nke a na-eduga na arụmọrụ ngwaọrụ ka mma, arụmọrụ, na ntụkwasị obi.

Q3: Gịnị bụ ụdị ngwa nke SiCOI wafers?

A: A na-eji ha na ngwa eletrọnịkị ike, ngwaọrụ RF dị elu, ihe mmetụta MEMS, ngwa eletrọnịkị dị elu, ngwaọrụ fotonic, na ngwa elektrọn siri ike radieshon.

Eserese zuru ezu