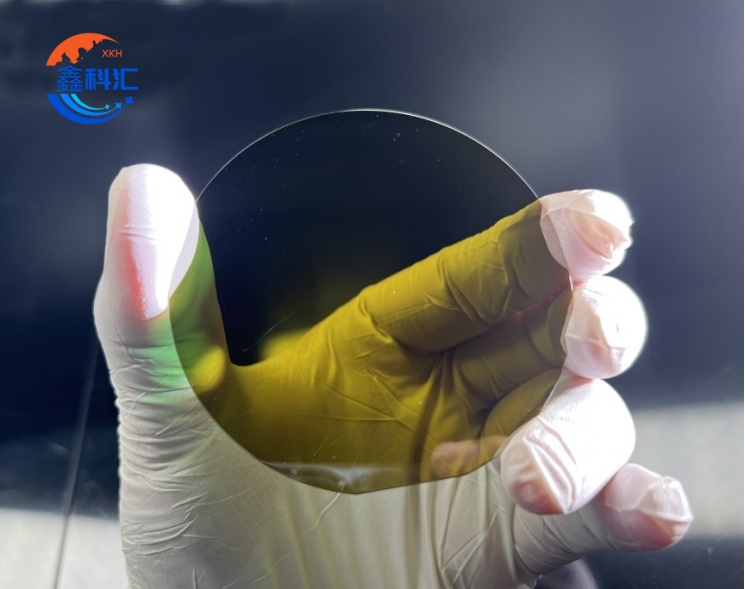

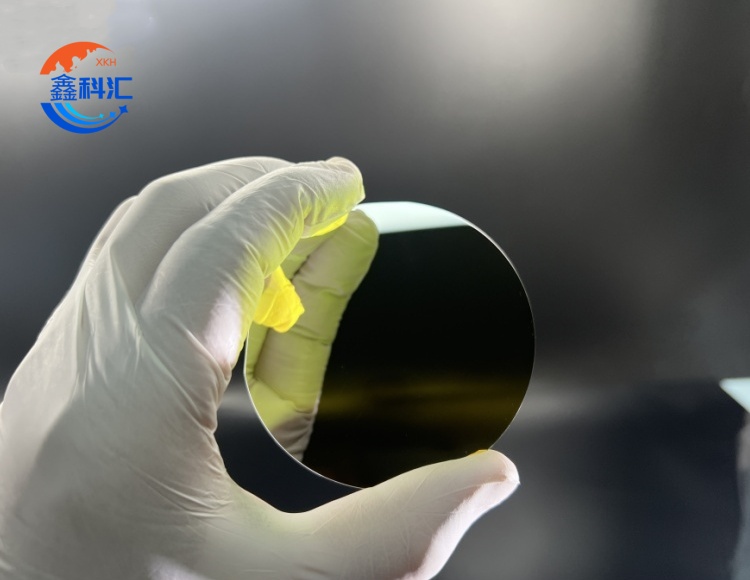

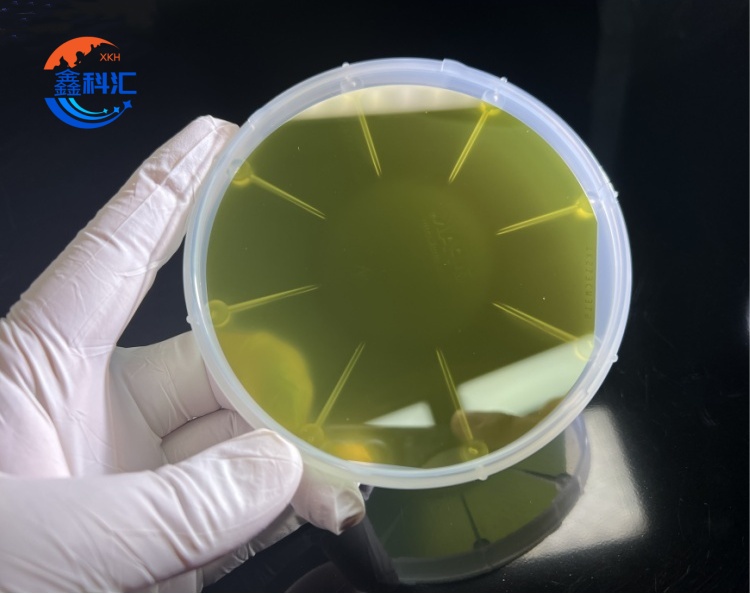

Ụdị Sic Substrate Silicon Carbide Wafer 4H-N Ụdị Isi Ike Corrosion Resistance Prime Grade Polishing

Ihe ndị a bụ njirimara nke silicon carbide wafer

1. Higher thermal conductivity: The thermal conductivity nke SIC wafers dị nnọọ elu karịa nke silicon, nke pụtara na SIC wafers nwere ike ikpochapụ okpomọkụ nke ọma ma dị mma maka ịrụ ọrụ na gburugburu okpomọkụ.

2. Ntugharị eletrọn dị elu: SIC wafers nwere igwe eletrik dị elu karịa silicon, na-ekwe ka ngwaọrụ SIC rụọ ọrụ na ọsọ ọsọ.

3. Voltage mgbawa dị elu: ihe SIC wafer nwere oke nkwụsịtụ dị elu, na-eme ka ọ dị mma maka ịmepụta ngwaọrụ semiconductor dị elu.

4. Nkwụsi ike nke kemịkalụ dị elu: SIC wafers nwere nguzogide corrosion kemịkalụ siri ike, nke na-enyere aka melite ntụkwasị obi na ịdịte aka nke ngwaọrụ ahụ.

5. Wider band ọdịiche: SIC wafers nwere a wider band ọdịiche karịa silicon, na-eme ka SIC ngwaọrụ mma na ọzọ kwụsie ike na elu okpomọkụ.

Silicon carbide wafer nwere ọtụtụ ngwa

1.Mechanical ubi: ịcha ngwá ọrụ na egweri ihe; Akụkụ na-eguzogide iyi na bushes; Valve ụlọ ọrụ na akara; Bọọlụ na bọọlụ

2.Electronic ike ubi: ike semiconductor ngwaọrụ; Eletrọnkị ngwa ngwa ugboro dị elu; Igwe ọkụ eletrik dị elu na ọkụ ọkụ dị elu; Ihe njikwa okpomọkụ

3.Chemical ụlọ ọrụ: chemical reactor na akụrụngwa; Ọkụ na-eguzogide corrosion na tankị nchekwa; Nkwado kemịkalụ

Ngalaba 4.Energy: gas turbine na turbocharger components; Isi ike nuklia na akụrụngwa akụrụngwa dị elu akụrụngwa mmanụ ọkụ

5.Aerospace: usoro nchebe okpomọkụ maka ngwa agha na ugbo ala; igwe ugboelu igwe ugbo elu; Ngwakọta dị elu

6.Ebe ndị ọzọ: Ihe mmetụta okpomọkụ dị elu na thermopiles; Nwụrụ na ngwá ọrụ maka usoro nhazi; Egweri na polishing na igbu ubi

ZMKJ nwere ike inye otu kristal SiC wafer (Silicon Carbide) dị elu na ụlọ ọrụ eletrọnịkị na optoelectronic. SiC wafer bụ ihe na-esote ọgbọ semiconductor, nwere akụrụngwa eletrik pụrụ iche na ihe ọkụkụ dị mma, ma e jiri ya tụnyere silicon wafer na GaAs wafer, SiC wafer dabara adaba maka oke okpomọkụ na ngwa ngwa ike dị elu. Enwere ike ịnye SiC wafer na dayameta 2-6 inch, ma 4H na 6H SiC, ụdị N, Nitrogen doped na ụdị mkpuchi nke ọkara dị. Biko kpọtụrụ anyị maka ozi ngwaahịa ọzọ.

Anyị factory nwere elu mmepụta ngwá na teknuzu otu, nke nwere ike hazie dị iche iche nkọwa, ọkpụrụkpụ na shapes nke SiC wafer dị ka ndị ahịa 'kpọmkwem chọrọ.

Eserese zuru ezu