4H-N HPSI SiC wafer 6H-N 6H-P 3C-N SiC Epitaxial wafer maka MOS ma ọ bụ SBD

Nchịkọta SiC Substrate SiC Epi-wafer Brief

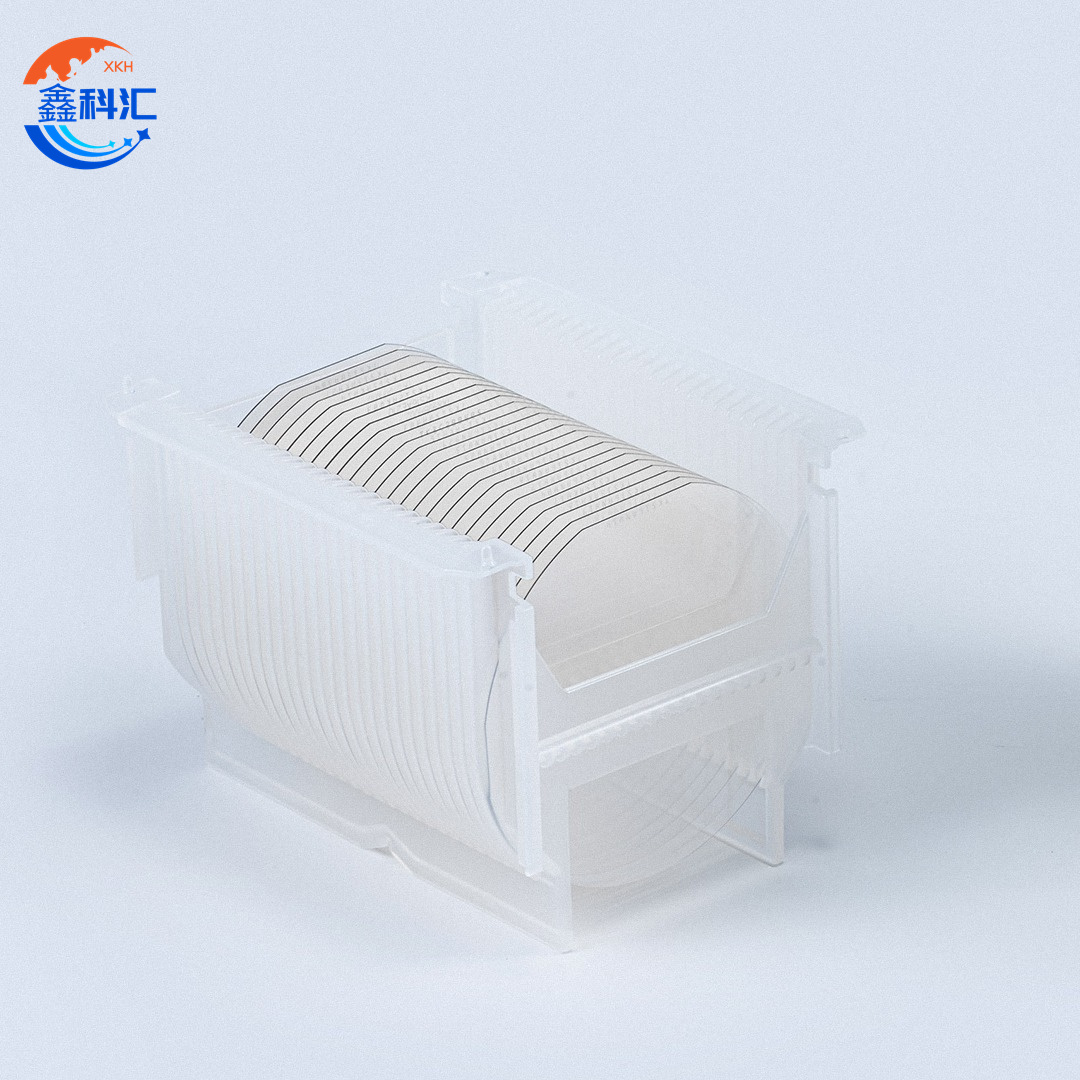

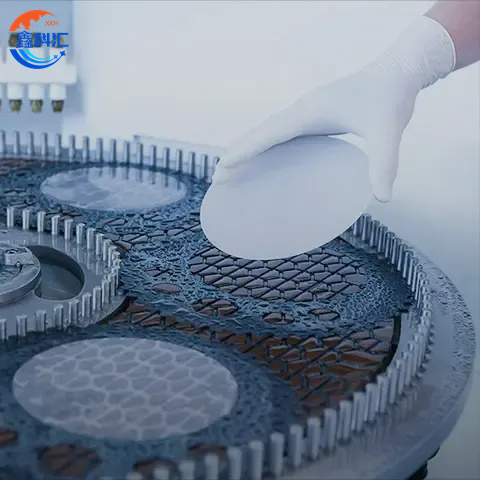

Anyị na-enye Pọtụfoliyo zuru oke nke mkpụrụ osisi SiC dị elu na sic wafers na ọtụtụ polytypes na profaịlụ doping-gụnyere 4H-N (n-ụdị conductive), 4H-P (p-ụdị conductive), 4H-HPSI (oke-ọcha ọkara mkpuchi), na 6H-P (p-ụdị conductive) — ″ na dayameta niile, 6. ruo 12 inch. Na agafeghị mkpụrụ osisi efu, ọrụ uto epi wafer agbakwunyere ọnụ ahịa na-ebuga wafers epitaxial (epi) nwere ọkpụrụkpụ ejiri chịkwaa (1-20 µm), mkpokọta doping, yana njupụta ntụpọ.

Sic wafer ọ bụla na epi wafer na-enweta nyocha in-line siri ike (njupụta micropipe <0.1 cm⁻², njupụta elu Ra <0.2 nm) yana njirimara eletrik zuru oke (CV, maapụ resistivity) iji hụ na ịdị n'otu kristal pụrụ iche na arụmọrụ. Ma ejiri ya maka modul eletrọnịkị ike, amplifiers RF dị elu, ma ọ bụ ngwaọrụ optoelectronic (LEDs, photodetectors), ahịrị ngwaahịa SiC anyị na ahịrị ngwaahịa epi wafer na-enye ntụkwasị obi, nkwụsi ike ọkụ, na ike ndakpọ nke ngwa kachasị achọ taa chọrọ.

Njirimara na ngwa ụdị SiC Substrate 4H-N

-

4H-N SiC ihe owuwu Polytype (Hexagonal).

Bandgap sara mbara nke ~ 3.26 eV na-eme ka arụmọrụ eletrik kwụsie ike na ike ọkụ n'okpuru ọnọdụ okpomọkụ na elu-ọkụ eletrik.

-

SiC mkpụrụN-Ụdị Doping

Nitrogen doping a na-achịkwa nke ọma na-ewepụta mkpokọta ihe na-ebu ibu site na 1 × 10¹⁶ ruo 1 × 10¹⁹ cm⁻³ yana igwe eletrọn na-ekpo ọkụ ruo ~ 900 cm²/V·s, na-ebelata mfu conduction.

-

SiC mkpụrụNnukwu Resistivity & Ịdị n'otu

Dị nso resistivity nso nke 0.01–10 Ω·cm na wafer ọkpụrụkpụ nke 350–650 µm nwere ±5% ndidi na ma doping na ọkpụrụkpụ—dị mma maka imepụta ngwaọrụ dị elu.

-

SiC mkpụrụNjupụta dị ala dị ala

Njupụta Micropipe <0.1 cm⁻² na njupụta basal-ụgbọ elu <500 cm⁻², na-ebuga> 99% mkpụrụ ngwaọrụ yana iguzosi ike n'ezi ihe kristal dị elu.

- SiC mkpụrụMmetụta okpomọkụ pụrụiche

Thermal conductivity ruo ~ 370 W / m · K na-eme ka ikpochapụ okpomọkụ dị mma, na-akwalite ntụkwasị obi ngwaọrụ na njupụta ike.

-

SiC mkpụrụNgwa ebumnuche

SiC MOSFETs, Schottky diodes, modul ike na ngwaọrụ RF maka draịva eletriki, ndị na-atụgharị anyanwụ, draịva ụlọ ọrụ, sistemu traction, na ahịa eletriki eletrik ndị ọzọ na-achọsi ike.

6inch 4H-N ụdị SiC nkọwapụta wafer | ||

| Ngwongwo | Ọkwa mmepụta MPD efu (ọkwa Z) | Ngụsị akwụkwọ (D grade) |

| Ọkwa | Ọkwa mmepụta MPD efu (ọkwa Z) | Ngụsị akwụkwọ (D grade) |

| Dayameta | 149.5 mm - 150.0 mm | 149.5 mm - 150.0 mm |

| Ụdị poly | 4H | 4H |

| Ọkpụrụkpụ | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Usoro Wafer | Gbanyụọ axis: 4.0° chere ihu <1120> ± 0.5° | Gbanyụọ axis: 4.0° chere ihu <1120> ± 0.5° |

| Njupụta Micropipe | ≤ 0.2 cm² | ≤ 15 cm² |

| Nguzogide | 0.015 - 0.024 Ω·cm | 0.015 - 0.028 Ω·cm |

| Nhazi Flat nke izizi | [10-10] ± 50° | [10-10] ± 50° |

| Ogologo Flat nke izizi | 475 mm ± 2.0 mm | 475 mm ± 2.0 mm |

| Mwepu ihu | 3 mm | 3 mm |

| LTV / TIV / Ụta / Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Isi ike | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Edge cracks Site na nnukwu ọkụ ọkụ | Ogologo ngụkọta ≤ 20 mm otu ogologo ≤ 2 mm | Ogologo ngụkọta ≤ 20 mm otu ogologo ≤ 2 mm |

| Efere Hex Site na Ìhè Dị Elu | Mpaghara mkpokọta ≤ 0.05% | Mpaghara mkpokọta ≤ 0.1% |

| Mpaghara Polytype Site n'ìhè dị elu | Mpaghara mkpokọta ≤ 0.05% | Mpaghara mkpokọta ≤ 3% |

| Ntinye Carbon Anya Anya | Mpaghara mkpokọta ≤ 0.05% | Mpaghara mkpokọta ≤ 5% |

| Silicon dị n'elu Scratches Site na nnukwu ọkụ ọkụ | Ogologo ngụkọta ≤ 1 dayameta wafer | |

| Chips Edge Site na Ìhè Dị Elu | Ọnweghị nke enyere ikike ≥ 0.2 mm obosara na omimi | 7 kwere, ≤ 1 mm nke ọ bụla |

| Mgbasa nke eriri eriri | <500 cm³ | <500 cm³ |

| Mmetọ Silicon dị n'elu site na ọkụ dị elu | ||

| Nkwakọ ngwaahịa | Cassette Multi-wafer ma ọ bụ otu akpa wafer | Cassette Multi-wafer ma ọ bụ otu akpa wafer |

8inch 4H-N ụdị SiC nkọwapụta wafer | ||

| Ngwongwo | Ọkwa mmepụta MPD efu (ọkwa Z) | Ngụsị akwụkwọ (D grade) |

| Ọkwa | Ọkwa mmepụta MPD efu (ọkwa Z) | Ngụsị akwụkwọ (D grade) |

| Dayameta | 199.5 mm - 200.0 mm | 199.5 mm - 200.0 mm |

| Ụdị poly | 4H | 4H |

| Ọkpụrụkpụ | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Usoro Wafer | 4.0° chere ihu <110> ± 0.5° | 4.0° chere ihu <110> ± 0.5° |

| Njupụta Micropipe | ≤ 0.2 cm² | ≤5 cm² |

| Nguzogide | 0.015 - 0.025 Ω·cm | 0.015 - 0.028 Ω·cm |

| Ezi ntụziaka | ||

| Mwepu ihu | 3 mm | 3 mm |

| LTV / TIV / Ụta / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Isi ike | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Edge cracks Site na nnukwu ọkụ ọkụ | Ogologo ngụkọta ≤ 20 mm otu ogologo ≤ 2 mm | Ogologo ngụkọta ≤ 20 mm otu ogologo ≤ 2 mm |

| Efere Hex Site na Ìhè Dị Elu | Mpaghara mkpokọta ≤ 0.05% | Mpaghara mkpokọta ≤ 0.1% |

| Mpaghara Polytype Site n'ìhè dị elu | Mpaghara mkpokọta ≤ 0.05% | Mpaghara mkpokọta ≤ 3% |

| Ntinye Carbon Anya Anya | Mpaghara mkpokọta ≤ 0.05% | Mpaghara mkpokọta ≤ 5% |

| Silicon dị n'elu Scratches Site na nnukwu ọkụ ọkụ | Ogologo ngụkọta ≤ 1 dayameta wafer | |

| Chips Edge Site na Ìhè Dị Elu | Ọnweghị nke enyere ikike ≥ 0.2 mm obosara na omimi | 7 kwere, ≤ 1 mm nke ọ bụla |

| Mgbasa nke eriri eriri | <500 cm³ | <500 cm³ |

| Mmetọ Silicon dị n'elu site na ọkụ dị elu | ||

| Nkwakọ ngwaahịa | Cassette Multi-wafer ma ọ bụ otu akpa wafer | Cassette Multi-wafer ma ọ bụ otu akpa wafer |

4H-SiC bụ ihe na-arụ ọrụ dị elu nke ejiri maka eletrik eletrik, ngwaọrụ RF, na ngwa okpomọkụ dị elu. "4H" na-ezo aka na nhazi kristal, nke dị hexagonal, na "N" na-egosi ụdị doping eji eme ka arụ ọrụ ihe dịkwuo elu.

Nke4H-SiCa na-ejikarị ụdị maka:

Igwe eletrọnịkị ike:Ejiri ya na ngwaọrụ dị ka diodes, MOSFETs, na IGBT maka ụgbọ ala eletrik, igwe mmepụta ihe, na sistemu ume ọhụrụ.

Teknụzụ 5G:Site n'ọchịchọ 5G maka ngwa ngwa dị elu yana arụmọrụ dị elu, ikike SiC nwere ijikwa voltaji dị elu ma rụọ ọrụ na oke okpomọkụ na-eme ka ọ dị mma maka amplifiers ike ọdụ na ngwaọrụ RF.

Sistemụ ike anyanwụ:Ngwongwo njikwa ike dị mma nke SiC dị mma maka ndị na-atụgharị fotovoltaic (ike anyanwụ) na ntụgharị.

Ụgbọ ala eletrik (EV):A na-eji SiC eme ihe na EV powertrains maka ntụgharị ike na-arụ ọrụ nke ọma, ọgbọ okpomọkụ dị ala, na njupụta ike dị elu.

Njirimara na ngwa nke ụdị SiC Substrate 4H Semi-Insulating

Njirimara:

-

Usoro njikwa njupụta na-enweghị Micropipe: Na-agba mbọ hụ na enweghị micropipes, na-emeziwanye mma mkpụrụ.

-

Usoro njikwa monocrystalline: Na-ekwe nkwa otu ihe owuwu kristal maka akụrụngwa ihe emelitere.

-

Usoro nchịkwa gụnyere: Na-ebelata ọnụnọ nke adịghị ọcha ma ọ bụ ntinye, na-ahụ na mkpụrụ dị ọcha.

-

Usoro njikwa nguzogide: Na-enye ohere maka njikwa ziri ezi nke mgbochi eletrik, nke dị mkpa maka ịrụ ọrụ ngwaọrụ.

-

Usoro nhazi na njikwa adịghị ọcha: Na-achịkwa ma na-amachi mmeghe nke adịghị ọcha iji nọgide na-eguzosi ike n'ezi ihe.

-

Usoro nchịkwa obosara nke nzọụkwụ: Na-enye njikwa ziri ezi n'elu obosara nzọụkwụ, na-eme ka ọ bụrụ ihe na-agbanwe agbanwe n'ofe mkpụrụ

6Inch 4H-semi SiC nkọwapụta mkpụrụ | ||

| Ngwongwo | Ọkwa mmepụta MPD efu (ọkwa Z) | Ngụsị akwụkwọ (D grade) |

| Dayameta (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| Ụdị poly | 4H | 4H |

| Ọkpụrụkpụ (um) | 500 ± 15 | 500 ± 25 |

| Usoro Wafer | Na axis: ± 0.0001° | Na axis: ± 0.05° |

| Njupụta Micropipe | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Nguzogide (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Nhazi Flat nke izizi | (0-10)° ± 5.0° | (10-10)° ± 5.0° |

| Ogologo Flat nke izizi | Ọkwa | Ọkwa |

| Mwepu ihu (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Bowl / Warp | ≤ 3µm | ≤ 3µm |

| Isi ike | Polish Ra ≤ 1.5 µm | Polish Ra ≤ 1.5 µm |

| Chips Edge Site na Ìhè Dị Elu | ≤20 µm | ≤60 µm |

| Efere ọkụ Site n'ìhè dị elu | Nchịkọta ≤ 0.05% | Nchịkọta ≤ 3% |

| Mpaghara Polytype Site n'ìhè dị elu | Mgbakwunye Carbon A na-ahụ anya ≤ 0.05% | Nchịkọta ≤ 3% |

| Silicon dị n'elu Scratches Site na nnukwu ọkụ ọkụ | ≤0.05% | Nchịkọta ≤ 4% |

| Chips Edge Site na Ìhè Dị Elu (Nha) | Ekweghị> 02 mm Obosara na Omimi | Ekweghị> 02 mm Obosara na Omimi |

| The Aiding Screw Dilation | ≤500 µm | ≤500 µm |

| Mmetọ Silicon dị n'elu site na ọkụ dị elu | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Nkwakọ ngwaahịa | Cassette Multi-wafer ma ọ bụ otu akpa wafer | Cassette Multi-wafer ma ọ bụ otu akpa wafer |

Nkọwapụta mkpụrụ nke SiC 4-inch 4H-Semi insulating

| Oke | Ọkwa mmepụta MPD efu (ọkwa Z) | Ngụsị akwụkwọ (D grade) |

|---|---|---|

| Njirimara anụ ahụ | ||

| Dayameta | 99.5 mm - 100.0 mm | 99.5 mm - 100.0 mm |

| Ụdị poly | 4H | 4H |

| Ọkpụrụkpụ | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Usoro Wafer | Na axis: <600h> 0.5° | Na axis: <000h> 0.5° |

| Ngwongwo eletriki | ||

| Njupụta Micropipe (MPD) | ≤1 cm ² | ≤15 cm ² |

| Nguzogide | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Nkwekọrịta geometric | ||

| Nhazi Flat nke izizi | (0x10) ± 5.0° | (0x10) ± 5.0° |

| Ogologo Flat nke izizi | 52.5 mm ± 2.0 mm | 52.5 mm ± 2.0 mm |

| Ogologo Flat nke abụọ | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| Nhazi Flat nke abụọ | 90° CW sitere na Prime flat ± 5.0° (Si ihu elu) | 90° CW sitere na Prime flat ± 5.0° (Si ihu elu) |

| Mwepu ihu | 3 mm | 3 mm |

| LTV / TTV / Ụta / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| Ogo elu | ||

| Ọdịmma dị n'elu (Polish Ra) | ≤1 nm | ≤1 nm |

| Ọdịmma dị n'elu (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Edge mgbawa (Ìhè dị elu) | Ekweghị | Ogologo ngụkọta ≥10 mm, otu mgbape ≤2 mm |

| Mmejọ Plate Hexagonal | ≤0.05% mkpokọta mpaghara | ≤0.1% mkpokọta mpaghara |

| Mpaghara nsonye Polytype | Ekweghị | ≤1% mkpokọta mpaghara |

| Ntinye Carbon Anya Anya | ≤0.05% mkpokọta mpaghara | ≤1% mkpokọta mpaghara |

| Silicon elu Scratches | Ekweghị | ≤1 wafer dayameta ngụkọta ogologo |

| ibe ibe | Ọnweghị ikike (≥0.2 mm obosara/omi) | ≤5 ibe (nke ọ bụla ≤1 mm) |

| Mmetọ Elu Silicon | Akọwapụtaghị ya | Akọwapụtaghị ya |

| Nkwakọ ngwaahịa | ||

| Nkwakọ ngwaahịa | Multi-wafer cassette ma ọ bụ otu-wafer akpa | Multi-wafer cassette ma ọ bụ |

Ngwa:

NkeSiC 4H ọkara mkpuchi ihea na-ejikarị eme ihe na ngwa eletrik dị elu na nke dị elu, karịsịa nangalaba RF. Ihe ndị a dị mkpa maka ngwa dị iche iche gụnyereusoro nkwukọrịta microwave, usoro radar na-agba ọsọ, naihe nchọpụta eletriki ikuku. Igwe ọkụ ọkụ ha dị elu na njirimara eletriki dị mma na-eme ka ha dị mma maka ngwa ngwa ngwa na ngwa eletriki na usoro nkwurịta okwu.

Njirimara na ngwa ụdị SiC epi wafer 4H-N

Njirimara na ngwa SiC 4H-N Ụdị Epi Wafer

Njirimara nke SiC 4H-N Ụdị Epi Wafer:

Ihe mejupụtara:

SiC (Silicon Carbide): Amara maka ike siri ike ya pụtara ìhè, nrụpụta ọkụ dị elu, yana akụrụngwa eletrik mara mma, SiC dị mma maka ngwaọrụ eletrọnịkị dị elu.

4H-SiC Polytype: A maara polytype 4H-SiC maka ịrụ ọrụ dị elu na nkwụsi ike na ngwa eletrọnịkị.

N-ụdị Doping: N-ụdị doping (doped na nitrogen) na-enye ọmarịcha njem elektrọn, na-eme ka SiC dị mma maka ngwa ngwa dị elu na ike dị elu.

Nrụpụta okpomọkụ dị elu:

SiC wafers nwere conductivity thermal dị elu, nke sitere na120–200 W/m·K, na-enye ha ohere ijikwa okpomọkụ nke ọma na ngwaọrụ ndị dị elu dị ka transistor na diodes.

Bandgap sara mbara:

Na bandgap nke3.26 nke eV, 4H-SiC nwere ike ịrụ ọrụ na voltaji dị elu, frequencies, na okpomọkụ ma e jiri ya tụnyere ngwaọrụ ndị dabeere na silicon, na-eme ka ọ dị mma maka arụmọrụ dị elu, ngwa ọrụ dị elu.

Ngwongwo eletriki:

Mbugharị eletrọn dị elu nke SiC na conductivity na-eme ka ọ dị mma maka yaike eletrọnịkị, na-enye ọsọ ọsọ na-agbanwe ngwa ngwa na ikike nchịkwa dị ugbu a na voltaji, na-eme ka usoro nchịkwa ike dịkwuo mma.

Mechanical na Chemical Resistance:

SiC bụ otu n'ime ihe ndị siri ike, nke abụọ na diamond, ma na-eguzogide oxidation na corrosion nke ukwuu, na-eme ka ọ dịgidere na gburugburu ebe siri ike.

Ngwa nke SiC 4H-N Ụdị Epi Wafer:

Igwe eletrọnịkị ike:

SiC 4H-N ụdị epi wafer na-ejikarị naike MOSFETs, Ndị IGBT, nadiodesmakantughari ikena sistemu dị kaanyanwụ inverters, ugbo ala eletrik, nausoro nchekwa ike, na-enye nkwalite arụmọrụ na ike ike.

Ụgbọ ala eletrik (EV):

In ụgbọ ala eletrik, ndị na-ahụ maka moto, naọdụ ụgbọ mmiri, SiC wafers na-enyere aka nweta arụmọrụ batrị ka mma, ịcha ngwa ngwa ngwa ngwa, ma kwalite ọrụ ike zuru ezu n'ihi ikike ha nwere ijikwa ike dị elu na okpomọkụ.

Usoro ume ọhụrụ:

Ndị ntụgharị anyanwụ: A na-eji wafer SiC eme iheusoro ike anyanwụmaka ịtụgharị ike DC site na akụkụ anyanwụ gaa na AC, na-abawanye arụmọrụ na arụmọrụ sistemụ n'ozuzu ya.

Igwe ikuku ikuku: A na-eji teknụzụ SiC arụ ọrụikuku turbine akara usoro, na-ebuli ike mmepụta ike na ngbanwe arụmọrụ.

Aerospace na nchekwa:

SiC wafers dị mma maka iji yaaerospace eletrọnịkịnangwa agha, gụnyereusoro radarnasatịlaịtị eletrọnịkị, ebe nnukwu nguzogide radieshon na nkwụsi ike nke okpomọkụ dị oke mkpa.

Ngwa dị elu na oke ọkụ:

SiC wafers kacha mmaelu-okpomọkụ electronics, eji naụgbọ elu engines, ugbo elu, naụlọ ọrụ kpo oku usoro, ka ha na-arụ ọrụ na oke okpomọkụ ọnọdụ. Na mgbakwunye, bandgap obosara ha na-enye ohere iji mee ihengwa ugboro ugborodị kaNgwa RFnankwukọrịta microwave.

| 6-inch N-ụdị Epit axial nkọwapụta | |||

| Oke | otu | Z-MOS | |

| Ụdị | Condutivity / Dopant | - | N-ụdị / Nitrogen |

| Ihe nchekwa oyi akwa | Ihe nchekwa oyi akwa | um | 1 |

| Nkwado oyi akwa oyi akwa | % | ± 20% | |

| Nchekwa oyi akwa | cm-3 | 1.00E+18 | |

| Nkwadebe Nleba Ntụkwasị Obi | % | ± 20% | |

| 1st Epi oyi akwa | Epi oyi akwa | um | 11.5 |

| Epi oyiri ịdị arọ | % | ± 4% | |

| Nlekere ịdị arọ nke Epi Layers ((Ọpụrụiche) Nke kacha, nke kacha nta)/Spec) | % | ±5% | |

| Epi Layer Concentration | cm-3 | 1E 15~ 1E 18 | |

| Nlegide Nleba Epi Layer | % | 6% | |

| Epi Layer Concentration Uniformity (σ / pụtara) | % | ≤5% | |

| Epi Layer Concentration Uniformity <(max-min)/(max+min> | % | ≤ 10% | |

| Ụdị Epitaixal Wafer | Ụta | um | ≤±20 |

| WARP | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| Njirimara izugbe | Ogologo nchara | mm | ≤30mm |

| ibe ibe | - | Ọ DỊGHỊ | |

| Nkọwapụta ntụpọ | ≥97% (Jiri 2*2 tụọ, Nrụrụ egbu egbu gụnyere: Mmejọ gụnyere Micropipe / nnukwu olulu, karọt, triangular | ||

| Mmetọ ígwè | atọm/cm² | d f f m ≤5E10 atọm/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| ngwugwu | Nkọwa nkwakọ ngwaahịa | pcs/igbe | multi-wafer cassette ma ọ bụ otu akpa wafer |

| 8-inch N-ụdị epitaxial nkọwapụta | |||

| Oke | otu | Z-MOS | |

| Ụdị | Condutivity / Dopant | - | N-ụdị / Nitrogen |

| oyi akwa mkpuchi | Ihe nchekwa oyi akwa | um | 1 |

| Nkwado oyi akwa oyi akwa | % | ± 20% | |

| Nchekwa oyi akwa | cm-3 | 1.00E+18 | |

| Nkwadebe Nleba Ntụkwasị Obi | % | ± 20% | |

| 1st Epi oyi akwa | Nkezi ịdị arọ Epi Layers | um | 8-12 |

| Epi Layers Ịdị n'ịdị arọ (σ/ pụtara) | % | ≤2.0 | |

| Nlegide ịdị arọ nke Epi Layers ((Spec -Max, Min)/Spec) | % | ±6 | |

| Epi Layers Net Nkezi Doping | cm-3 | 8E+15 ~2E+16 | |

| Epi Layers Net Doping Uniformity (σ/ pụtara) | % | ≤5 | |

| Epi Layers Net DopingTolerance((Spec-Max, | % | ± 10.0 | |

| Ụdị Epitaixal Wafer | Mi )/S) Warp | um | ≤50.0 |

| Ụta | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm × 10mm) | |

| Izugbe Njirimara | Ọkpụkpụ | - | Ogologo ngụkọta ≤ 1/2 dayameta wafer |

| ibe ibe | - | ≤2 ibe, radius ọ bụla≤1.5mm | |

| Mmetọ Ọla dị n'elu | atom / cm2 | ≤5E10 atọm/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Nyocha ntụpọ | % | ≥ 96.0 (Nkwarụ 2X2 gụnyere Micropipe / nnukwu olulu, Karọt, ntụpọ triangular, ọdịda, Linear/IGSF-s, BPD) | |

| Mmetọ Ọla dị n'elu | atom / cm2 | ≤5E10 atọm/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| ngwugwu | Nkọwa nkwakọ ngwaahịa | - | multi-wafer cassette ma ọ bụ otu akpa wafer |

Ajụjụ&A nke SiC wafer

Q1: Gịnị bụ isi uru nke iji SiC wafers n'elu omenala silicon wafer na ike electronics?

A1:

SiC wafers na-enye ọtụtụ uru dị mkpa karịa wafer silicon (Si) ọdịnala na ngwa eletrọnịkị ike, gụnyere:

Ịrụ ọrụ dị elu: SiC nwere bandgap sara mbara (3.26 eV) ma e jiri ya tụnyere silicon (1.1 eV), na-ekwe ka ngwaọrụ rụọ ọrụ na voltaji dị elu, frequencies, na okpomọkụ. Nke a na-eduga na mfu ike dị ala na arụmọrụ dị elu na usoro ntụgharị ike.

Omume okpomọkụ dị elu: SiC's thermal conductivity dị elu karịa nke silicon, na-eme ka ikpo ọkụ dị mma na ngwa ike dị elu, nke na-eme ka ntụkwasị obi na ndụ nke ngwaọrụ ike dịkwuo mma.

Voltaji dị elu na njikwa ugbu a: Ngwa SiC nwere ike ijikwa voltaji dị elu na ọkwa dị ugbu a, na-eme ka ha dabara maka ngwa ike dị elu dị ka ụgbọ ala eletrik, usoro ume ọhụrụ, na moto ụlọ ọrụ mmepụta ihe.

Ọsọ ngbanwe ngwa ngwa: Ngwa SiC nwere ike ịgbanwe ngwa ngwa, nke na-enye aka na mbelata ume ike na nha usoro, na-eme ka ha dị mma maka ngwa ngwa dị elu.

Q2: Gịnị bụ isi ngwa nke SiC wafers na ụgbọ ala ụlọ ọrụ?

A2:

N'ime ụlọ ọrụ ụgbọ ala, a na-eji wafer SiC eme ihe na:

Ụgbọ ala eletriki (EV) Powertrains: Ngwa ndị dabeere na SiC dị kainvertersnaike MOSFETsmelite arụmọrụ na ịrụ ọrụ nke ụgbọ ala eletrik site n'ịkwalite ọsọ ọsọ ọsọ na njupụta ume dị elu. Nke a na-eduga ndụ batrị ogologo yana ịrụ ọrụ ụgbọ ala ka mma.

Ndị chaja na bọọdụ: Ngwa SiC na-enyere aka melite arụmọrụ nke sistemu ịchaji na bọọdụ site n'ịkwalite oge chaja ngwa ngwa na njikwa ọkụ ka mma, nke dị oke mkpa maka EVs iji kwado ọdụ ụgbọ mmiri dị elu.

Sistemu njikwa batrị (BMS): Teknụzụ SiC na-eme ka arụmọrụ dị mmausoro njikwa batrị, na-enye ohere maka ụkpụrụ voltaji ka mma, njikwa ike dị elu, na ogologo ndụ batrị.

Ndị ntụgharị DC-DC: A na-eji wafer SiC eme iheNdị ntụgharị DC-DCiji gbanwee ike DC dị elu ka ọ bụrụ obere voltaji DC nke ọma karị, nke dị oke mkpa na ụgbọ ala eletrik iji jikwaa ike site na batrị gaa na ihe dị iche iche n'ime ụgbọ ala ahụ.

Ịrụ ọrụ dị elu nke SiC na nnukwu voltaji, okpomọkụ dị elu na ngwa dị elu na-eme ka ọ dị mkpa maka mgbanwe nke ụlọ ọrụ ụgbọ ala na-agagharị na eletriki.

6inch 4H-N ụdị SiC nkọwapụta wafer | ||

| Ngwongwo | Ọkwa mmepụta MPD efu (ọkwa Z) | Ngụsị akwụkwọ (D grade) |

| Ọkwa | Ọkwa mmepụta MPD efu (ọkwa Z) | Ngụsị akwụkwọ (D grade) |

| Dayameta | 149.5 mm - 150.0 mm | 149.5 mm - 150.0 mm |

| Ụdị poly | 4H | 4H |

| Ọkpụrụkpụ | 350 µm ± 15 µm | 350 µm ± 25 µm |

| Usoro Wafer | Gbanyụọ axis: 4.0° chere ihu <1120> ± 0.5° | Gbanyụọ axis: 4.0° chere ihu <1120> ± 0.5° |

| Njupụta Micropipe | ≤ 0.2 cm² | ≤ 15 cm² |

| Nguzogide | 0.015 - 0.024 Ω·cm | 0.015 - 0.028 Ω·cm |

| Nhazi Flat nke izizi | [10-10] ± 50° | [10-10] ± 50° |

| Ogologo Flat nke izizi | 475 mm ± 2.0 mm | 475 mm ± 2.0 mm |

| Mwepu ihu | 3 mm | 3 mm |

| LTV / TIV / Ụta / Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Isi ike | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Edge cracks Site na nnukwu ọkụ ọkụ | Ogologo ngụkọta ≤ 20 mm otu ogologo ≤ 2 mm | Ogologo ngụkọta ≤ 20 mm otu ogologo ≤ 2 mm |

| Efere Hex Site na Ìhè Dị Elu | Mpaghara mkpokọta ≤ 0.05% | Mpaghara mkpokọta ≤ 0.1% |

| Mpaghara Polytype Site n'ìhè dị elu | Mpaghara mkpokọta ≤ 0.05% | Mpaghara mkpokọta ≤ 3% |

| Ntinye Carbon Anya Anya | Mpaghara mkpokọta ≤ 0.05% | Mpaghara mkpokọta ≤ 5% |

| Silicon dị n'elu Scratches Site na nnukwu ọkụ ọkụ | Ogologo ngụkọta ≤ 1 dayameta wafer | |

| Chips Edge Site na Ìhè Dị Elu | Ọnweghị nke enyere ikike ≥ 0.2 mm obosara na omimi | 7 kwere, ≤ 1 mm nke ọ bụla |

| Mgbasa nke eriri eriri | <500 cm³ | <500 cm³ |

| Mmetọ Silicon dị n'elu site na ọkụ dị elu | ||

| Nkwakọ ngwaahịa | Cassette Multi-wafer ma ọ bụ otu akpa wafer | Cassette Multi-wafer ma ọ bụ otu akpa wafer |

8inch 4H-N ụdị SiC nkọwapụta wafer | ||

| Ngwongwo | Ọkwa mmepụta MPD efu (ọkwa Z) | Ngụsị akwụkwọ (D grade) |

| Ọkwa | Ọkwa mmepụta MPD efu (ọkwa Z) | Ngụsị akwụkwọ (D grade) |

| Dayameta | 199.5 mm - 200.0 mm | 199.5 mm - 200.0 mm |

| Ụdị poly | 4H | 4H |

| Ọkpụrụkpụ | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Usoro Wafer | 4.0° chere ihu <110> ± 0.5° | 4.0° chere ihu <110> ± 0.5° |

| Njupụta Micropipe | ≤ 0.2 cm² | ≤5 cm² |

| Nguzogide | 0.015 - 0.025 Ω·cm | 0.015 - 0.028 Ω·cm |

| Ezi ntụziaka | ||

| Mwepu ihu | 3 mm | 3 mm |

| LTV / TIV / Ụta / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Isi ike | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Edge cracks Site na nnukwu ọkụ ọkụ | Ogologo ngụkọta ≤ 20 mm otu ogologo ≤ 2 mm | Ogologo ngụkọta ≤ 20 mm otu ogologo ≤ 2 mm |

| Efere Hex Site na Ìhè Dị Elu | Mpaghara mkpokọta ≤ 0.05% | Mpaghara mkpokọta ≤ 0.1% |

| Mpaghara Polytype Site n'ìhè dị elu | Mpaghara mkpokọta ≤ 0.05% | Mpaghara mkpokọta ≤ 3% |

| Ntinye Carbon Anya Anya | Mpaghara mkpokọta ≤ 0.05% | Mpaghara mkpokọta ≤ 5% |

| Silicon dị n'elu Scratches Site na nnukwu ọkụ ọkụ | Ogologo ngụkọta ≤ 1 dayameta wafer | |

| Chips Edge Site na Ìhè Dị Elu | Ọnweghị nke enyere ikike ≥ 0.2 mm obosara na omimi | 7 kwere, ≤ 1 mm nke ọ bụla |

| Mgbasa nke eriri eriri | <500 cm³ | <500 cm³ |

| Mmetọ Silicon dị n'elu site na ọkụ dị elu | ||

| Nkwakọ ngwaahịa | Cassette Multi-wafer ma ọ bụ otu akpa wafer | Cassette Multi-wafer ma ọ bụ otu akpa wafer |

6Inch 4H-semi SiC nkọwapụta mkpụrụ | ||

| Ngwongwo | Ọkwa mmepụta MPD efu (ọkwa Z) | Ngụsị akwụkwọ (D grade) |

| Dayameta (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| Ụdị poly | 4H | 4H |

| Ọkpụrụkpụ (um) | 500 ± 15 | 500 ± 25 |

| Usoro Wafer | Na axis: ± 0.0001° | Na axis: ± 0.05° |

| Njupụta Micropipe | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Nguzogide (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Nhazi Flat nke izizi | (0-10)° ± 5.0° | (10-10)° ± 5.0° |

| Ogologo Flat nke izizi | Ọkwa | Ọkwa |

| Mwepu ihu (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / Bowl / Warp | ≤ 3µm | ≤ 3µm |

| Isi ike | Polish Ra ≤ 1.5 µm | Polish Ra ≤ 1.5 µm |

| Chips Edge Site na Ìhè Dị Elu | ≤20 µm | ≤60 µm |

| Efere ọkụ Site n'ìhè dị elu | Nchịkọta ≤ 0.05% | Nchịkọta ≤ 3% |

| Mpaghara Polytype Site n'ìhè dị elu | Mgbakwunye Carbon A na-ahụ anya ≤ 0.05% | Nchịkọta ≤ 3% |

| Silicon dị n'elu Scratches Site na nnukwu ọkụ ọkụ | ≤0.05% | Nchịkọta ≤ 4% |

| Chips Edge Site na Ìhè Dị Elu (Nha) | Ekweghị> 02 mm Obosara na Omimi | Ekweghị> 02 mm Obosara na Omimi |

| The Aiding Screw Dilation | ≤500 µm | ≤500 µm |

| Mmetọ Silicon dị n'elu site na ọkụ dị elu | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Nkwakọ ngwaahịa | Cassette Multi-wafer ma ọ bụ otu akpa wafer | Cassette Multi-wafer ma ọ bụ otu akpa wafer |

Nkọwapụta mkpụrụ nke SiC 4-inch 4H-Semi insulating

| Oke | Ọkwa mmepụta MPD efu (ọkwa Z) | Ngụsị akwụkwọ (D grade) |

|---|---|---|

| Njirimara anụ ahụ | ||

| Dayameta | 99.5 mm - 100.0 mm | 99.5 mm - 100.0 mm |

| Ụdị poly | 4H | 4H |

| Ọkpụrụkpụ | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Usoro Wafer | Na axis: <600h> 0.5° | Na axis: <000h> 0.5° |

| Ngwongwo eletriki | ||

| Njupụta Micropipe (MPD) | ≤1 cm ² | ≤15 cm ² |

| Nguzogide | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Nkwekọrịta geometric | ||

| Nhazi Flat nke izizi | (0×10) ± 5.0° | (0×10) ± 5.0° |

| Ogologo Flat nke izizi | 52.5 mm ± 2.0 mm | 52.5 mm ± 2.0 mm |

| Ogologo Flat nke abụọ | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| Nhazi Flat nke abụọ | 90° CW sitere na Prime flat ± 5.0° (Si ihu elu) | 90° CW sitere na Prime flat ± 5.0° (Si ihu elu) |

| Mwepu ihu | 3 mm | 3 mm |

| LTV / TTV / Ụta / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| Ogo elu | ||

| Ọdịmma dị n'elu (Polish Ra) | ≤1 nm | ≤1 nm |

| Ọdịmma dị n'elu (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Edge mgbawa (Ìhè dị elu) | Ekweghị | Ogologo ngụkọta ≥10 mm, otu mgbape ≤2 mm |

| Mmejọ Plate Hexagonal | ≤0.05% mkpokọta mpaghara | ≤0.1% mkpokọta mpaghara |

| Mpaghara nsonye Polytype | Ekweghị | ≤1% mkpokọta mpaghara |

| Ntinye Carbon Anya Anya | ≤0.05% mkpokọta mpaghara | ≤1% mkpokọta mpaghara |

| Silicon elu Scratches | Ekweghị | ≤1 wafer dayameta ngụkọta ogologo |

| ibe ibe | Ọnweghị ikike (≥0.2 mm obosara/omi) | ≤5 ibe (nke ọ bụla ≤1 mm) |

| Mmetọ Elu Silicon | Akọwapụtaghị ya | Akọwapụtaghị ya |

| Nkwakọ ngwaahịa | ||

| Nkwakọ ngwaahịa | Multi-wafer cassette ma ọ bụ otu-wafer akpa | Multi-wafer cassette ma ọ bụ |

| 6-inch N-ụdị Epit axial nkọwapụta | |||

| Oke | otu | Z-MOS | |

| Ụdị | Condutivity / Dopant | - | N-ụdị / Nitrogen |

| Ihe nchekwa oyi akwa | Ihe nchekwa oyi akwa | um | 1 |

| Nkwado oyi akwa oyi akwa | % | ± 20% | |

| Nchekwa oyi akwa | cm-3 | 1.00E+18 | |

| Nkwadebe Nleba Ntụkwasị Obi | % | ± 20% | |

| 1st Epi oyi akwa | Epi oyi akwa | um | 11.5 |

| Epi oyiri ịdị arọ | % | ± 4% | |

| Nlekere ịdị arọ nke Epi Layers ((Ọpụrụiche) Nke kacha, nke kacha nta)/Spec) | % | ±5% | |

| Epi Layer Concentration | cm-3 | 1E 15~ 1E 18 | |

| Nlegide Nleba Epi Layer | % | 6% | |

| Epi Layer Concentration Uniformity (σ / pụtara) | % | ≤5% | |

| Epi Layer Concentration Uniformity <(max-min)/(max+min> | % | ≤ 10% | |

| Ụdị Epitaixal Wafer | Ụta | um | ≤±20 |

| WARP | um | ≤30 | |

| TTV | um | ≤ 10 | |

| LTV | um | ≤2 | |

| Njirimara izugbe | Ogologo nchara | mm | ≤30mm |

| ibe ibe | - | Ọ DỊGHỊ | |

| Nkọwapụta ntụpọ | ≥97% (Jiri 2*2 tụọ, Nrụrụ egbu egbu gụnyere: Mmejọ gụnyere Micropipe / nnukwu olulu, karọt, triangular | ||

| Mmetọ ígwè | atọm/cm² | d f f m ≤5E10 atọm/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| ngwugwu | Nkọwa nkwakọ ngwaahịa | pcs/igbe | multi-wafer cassette ma ọ bụ otu akpa wafer |

| 8-inch N-ụdị epitaxial nkọwapụta | |||

| Oke | otu | Z-MOS | |

| Ụdị | Condutivity / Dopant | - | N-ụdị / Nitrogen |

| oyi akwa mkpuchi | Ihe nchekwa oyi akwa | um | 1 |

| Nkwado oyi akwa oyi akwa | % | ± 20% | |

| Nchekwa oyi akwa | cm-3 | 1.00E+18 | |

| Nkwadebe Nleba Ntụkwasị Obi | % | ± 20% | |

| 1st Epi oyi akwa | Nkezi ịdị arọ Epi Layers | um | 8-12 |

| Epi Layers Ịdị n'ịdị arọ (σ/ pụtara) | % | ≤2.0 | |

| Nlegide ịdị arọ nke Epi Layers ((Spec -Max, Min)/Spec) | % | ±6 | |

| Epi Layers Net Nkezi Doping | cm-3 | 8E+15 ~2E+16 | |

| Epi Layers Net Doping Uniformity (σ/ pụtara) | % | ≤5 | |

| Epi Layers Net DopingTolerance((Spec-Max, | % | ± 10.0 | |

| Ụdị Epitaixal Wafer | Mi )/S) Warp | um | ≤50.0 |

| Ụta | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm × 10mm) | |

| Izugbe Njirimara | Ọkpụkpụ | - | Ogologo ngụkọta ≤ 1/2 dayameta wafer |

| ibe ibe | - | ≤2 ibe, radius ọ bụla≤1.5mm | |

| Mmetọ Ọla dị n'elu | atom / cm2 | ≤5E10 atọm/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| Nyocha ntụpọ | % | ≥ 96.0 (Nkwarụ 2X2 gụnyere Micropipe / nnukwu olulu, Karọt, ntụpọ triangular, ọdịda, Linear/IGSF-s, BPD) | |

| Mmetọ Ọla dị n'elu | atom / cm2 | ≤5E10 atọm/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K, Ti, Ca &Mn) | |

| ngwugwu | Nkọwa nkwakọ ngwaahịa | - | multi-wafer cassette ma ọ bụ otu akpa wafer |

Q1: Gịnị bụ isi uru nke iji SiC wafers n'elu omenala silicon wafer na ike electronics?

A1:

SiC wafers na-enye ọtụtụ uru dị mkpa karịa wafer silicon (Si) ọdịnala na ngwa eletrọnịkị ike, gụnyere:

Ịrụ ọrụ dị elu: SiC nwere bandgap sara mbara (3.26 eV) ma e jiri ya tụnyere silicon (1.1 eV), na-ekwe ka ngwaọrụ rụọ ọrụ na voltaji dị elu, frequencies, na okpomọkụ. Nke a na-eduga na mfu ike dị ala na arụmọrụ dị elu na usoro ntụgharị ike.

Omume okpomọkụ dị elu: SiC's thermal conductivity dị elu karịa nke silicon, na-eme ka ikpo ọkụ dị mma na ngwa ike dị elu, nke na-eme ka ntụkwasị obi na ndụ nke ngwaọrụ ike dịkwuo mma.

Voltaji dị elu na njikwa ugbu a: Ngwa SiC nwere ike ijikwa voltaji dị elu na ọkwa dị ugbu a, na-eme ka ha dabara maka ngwa ike dị elu dị ka ụgbọ ala eletrik, usoro ume ọhụrụ, na moto ụlọ ọrụ mmepụta ihe.

Ọsọ ngbanwe ngwa ngwa: Ngwa SiC nwere ike ịgbanwe ngwa ngwa, nke na-enye aka na mbelata ume ike na nha usoro, na-eme ka ha dị mma maka ngwa ngwa dị elu.

Q2: Gịnị bụ isi ngwa nke SiC wafers na ụgbọ ala ụlọ ọrụ?

A2:

N'ime ụlọ ọrụ ụgbọ ala, a na-eji wafer SiC eme ihe na:

Ụgbọ ala eletriki (EV) Powertrains: Ngwa ndị dabeere na SiC dị kainvertersnaike MOSFETsmelite arụmọrụ na ịrụ ọrụ nke ụgbọ ala eletrik site n'ịkwalite ọsọ ọsọ ọsọ na njupụta ume dị elu. Nke a na-eduga ndụ batrị ogologo yana ịrụ ọrụ ụgbọ ala ka mma.

Ndị chaja na bọọdụ: Ngwa SiC na-enyere aka melite arụmọrụ nke sistemu ịchaji na bọọdụ site n'ịkwalite oge chaja ngwa ngwa na njikwa ọkụ ka mma, nke dị oke mkpa maka EVs iji kwado ọdụ ụgbọ mmiri dị elu.

Sistemu njikwa batrị (BMS): Teknụzụ SiC na-eme ka arụmọrụ dị mmausoro njikwa batrị, na-enye ohere maka ụkpụrụ voltaji ka mma, njikwa ike dị elu, na ogologo ndụ batrị.

Ndị ntụgharị DC-DC: A na-eji wafer SiC eme iheNdị ntụgharị DC-DCiji gbanwee ike DC dị elu ka ọ bụrụ obere voltaji DC nke ọma karị, nke dị oke mkpa na ụgbọ ala eletrik iji jikwaa ike site na batrị gaa na ihe dị iche iche n'ime ụgbọ ala ahụ.

Ịrụ ọrụ dị elu nke SiC na nnukwu voltaji, okpomọkụ dị elu na ngwa dị elu na-eme ka ọ dị mkpa maka mgbanwe nke ụlọ ọrụ ụgbọ ala na-agagharị na eletriki.