SiC Ceramic Tray maka onye na-ebu Wafer nwere nguzogide oke okpomọkụ

Silicon Carbide Ceramic Tray (SiC Tray)

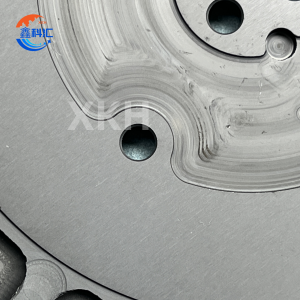

Ngwa seramiiki na-arụ ọrụ dị elu dabere na silicon carbide (SiC), emebere maka ngwa ụlọ ọrụ dị elu dị ka nrụpụta semiconductor na mmepụta LED. Ọrụ ya bụ isi gụnyere ije ozi dị ka onye na-ebu wafer, ikpo okwu usoro etching, ma ọ bụ nkwado usoro okpomọkụ dị elu, na-eleba anya nhụsianya okpomọkụ pụrụ iche, nkwụsi ike okpomọkụ, na nkwụsi ike kemịkalụ iji hụ na usoro nhazi na mkpụrụ ngwaahịa.

Akụkụ ndị isi

1. Thermal Performance

- Igwe ọkụ dị elu: 140-300 W / m·K, karịrị nke ukwuu graphite ọdịnala (85 W / m·K), na-eme ka ikpochapụ ọkụ ngwa ngwa ma belata nrụgide okpomọkụ.

- Ọnụ ego mgbasawanye dị ala: 4.0 × 10⁻⁶ / ℃ (25-1000 ℃), silicon dakọtara (2.6 × 10⁻⁶ / ℃), na-ebelata ihe egwu nrụrụ ọkụ.

2. Mechanical Properties

- Ike dị elu: ike mgbanwe ≥320 MPa (20 ℃), na-eguzogide mkpakọ na mmetụta.

- Ike siri ike: Mohs hardness 9.5, nke abụọ na diamond, na-enye nguzogide iyi ka mma.

3. Chemical kwụsie ike

- Nguzogide corrosion: na-eguzogide acid siri ike (dịka, HF, H₂SO₄), dabara maka gburugburu usoro etching.

- Na-abụghị Magnetik: ike ndọta dị n'ime <1×10⁻⁶ emu/g, na-ezere nnyonye anya na ngwa ngwa.

4. Oke nnabata gburugburu ebe obibi

- Ogologo Okpomọkụ dị elu: Ogologo oge na-arụ ọrụ okpomọkụ ruo 1600-1900 ℃; obere oge na-eguzogide ruo 2200 ℃ (obere ikuku oxygen).

- Nguzogide okpomọkụ nke okpomọkụ: Na-egbochi mgbanwe okpomọkụ mberede (ΔT> 1000 ℃) na-enweghị mgbawa.

Ngwa

| Mpaghara Ngwa | Ihe ngosi akọwapụtara | Uru teknụzụ |

| Mmepụta Semiconductor | Wafer etching (ICP), ntinye ihe nkiri dị mkpa (MOCVD), polishing CMP | High thermal conductivity ana achi achi n'otu ọnọdụ okpomọkụ ubi; Mgbasa ọkụ dị ala na-ebelata wafer warpage. |

| Mmepụta LED | Uto epitaxial (dịka ọmụmaatụ, GaN), ịkụ nkụ wafer, nkwakọ ngwaahịa | Na-egbochi ntụpọ ụdị dị iche iche, na-eme ka arụmọrụ ọkụ LED dịkwuo mma na ogologo ndụ. |

| Ụlọ ọrụ Photovoltaic | Silicon wafer sintering oven, PECVD akụrụngwa na-akwado | Okpomọkụ dị elu na nguzogide ujo na-agbatị ndụ akụrụngwa. |

| Laser & Optics | Igwe ọkụ ọkụ laser dị elu, sistemụ ngwa anya na-akwado | Igwe ọkụ dị elu na-eme ka ọkụ ọkụ na-ekpo ọkụ ngwa ngwa, na-eme ka ihe ndị na-ahụ anya na-eme ka ọ dị ike. |

| Ngwa nyocha | Ndị na-ejide ihe atụ TGA/DSC | Ikike okpomọkụ dị ala na nzaghachi ọkụ ngwa ngwa na-eme ka nha nha nha nha. |

Uru ngwaahịa

- Arụmọrụ zuru oke: conductivity thermal, ike, na nguzogide corrosion karịrị alumina na silicon nitride ceramics, na-egbo oke arụ ọrụ chọrọ.

- Ngosipụta dị fechaa: Njupụta nke 3.1-3.2 g/cm³ (40% nke ígwè), na-ebelata ibu inertial ma na-eme ka ọ dịkwuo mma.

- Ogologo ndụ & ntụkwasị obi: Ndụ ọrụ karịrị afọ 5 na 1600 ℃, na-ebelata oge nkwụsịtụ na ibelata ụgwọ ọrụ site na 30%.

- Nhazi: Na-akwado geometries gbagwojuru anya (dịka ọmụmaatụ, iko mmiri ara ehi, trays multilayer) nwere mperi dị larịị <15 μm maka ngwa ziri ezi.

Nkọwa nka nka

| Parameter Category | Ihe ngosi |

| Njirimara anụ ahụ | |

| Njupụta | ≥3.10 g/cm³ |

| Ike Flexural (20℃) | 320-410 MPa |

| Nrụpụta ọkụ (20 ℃) | 140–300 W/(m·K) |

| Ọnụego Mgbasawanye okpomọkụ (25-1000 ℃) | 4.0 × 10 ⁻ / ℃ |

| Njirimara kemịkalụ | |

| Nguzogide Acid (HF/H₂SO₄) | Enweghị corrosion mgbe imikpu elekere 24 gachara |

| Machining nkenke | |

| Ịdị nro | ≤15 μm (300×300 mm) |

| Ọdịiche dị n'elu (Ra) | ≤0.4 μm |

Ọrụ XKH

XKH na-enye ngwọta ụlọ ọrụ zuru oke gbasara mmepe omenala, nhazi nke ọma, na njikwa mma siri ike. Maka mmepe omenala, ọ na-enye ịdị ọcha dị elu (> 99.999%) na ihe ngwọta nke porous (30-50% porosity), jikọtara ya na ihe ngosi 3D na ịme anwansị iji kwalite geometry mgbagwoju anya maka ngwa dị ka semiconductor na aerospace. Ịrụ ọrụ nkenke na-agbaso usoro nhazi: nhazi ntụ ntụ → isostatic / akọrọ ịpị → 2200 ° C sintering → CNC / diamond egweri → nyocha, na-eme ka nanometer-larịị polishing na ± 0.01 mm akụkụ ndidi. Njikwa ogo na-agụnye ule nhazi zuru oke (ihe mejupụtara XRD, microstructure SEM, 3-point-ehulata) na nkwado teknụzụ (njikarịcha usoro, nyocha 24/7, nnyefe nlele elekere 48), na-ebuga ihe ndị a pụrụ ịdabere na ya, arụmọrụ dị elu maka mkpa ụlọ ọrụ dị elu.

Ajụjụ A na-ajụkarị (FAQ)

1. Ajụjụ: Kedu ụlọ ọrụ na-eji silicon carbide seramiiki trays?

A: A na-ejikarị eme ihe n'ichepụta semiconductor (wafer njikwa), ike anyanwụ (usoro PECVD), akụrụngwa ahụike (MRI components), na ikuku ikuku (akụkụ dị elu) n'ihi oke okpomọkụ ha na nkwụsi ike kemịkalụ.

2. Ajụjụ: Kedu ka silicon carbide si arụ ọrụ quartz/glass trays?

A: Nguzogide ujo dị elu dị elu (ruo 1800°C vs. quartz's 1100°C), nnyonye anya magnetik efu, na ogologo ndụ ogologo (afọ 5+ vs. quartz's 6-12 months).

3. Ajụjụ: Silikoni carbide trays nwere ike ijikwa gburugburu acidic?

A: Ee. Na-eguzogide HF, H2SO4, na NaOH na <0.01mm corrosion/afọ, na-eme ka ha dị mma maka etching kemịkal na ihicha wafer.

4. Ajụjụ: Silikoni carbide trays dakọtara na akpaaka?

A: Ee. Emebere ya maka ijikwa oghere na njikwa rọbọt, nke nwere oke elu <0.01mm iji gbochie mmetọ ahụ n'ime akwa akpaaka.

5. Ajụjụ: Gịnị bụ ọnụ ahịa ntụnyere vs. omenala ihe?

A: Ọnụ ụzọ dị elu dị elu (3-5x quartz) mana 30-50% TCO dị ala n'ihi ogologo ndụ ogologo oge, belata oge nkwụsị, na nchekwa ike site na nrụpụta ọkụ dị elu.