Ihe eji eme ihe na-ebuli ihe laser nke Semiconductor

Eserese zuru ezu

Nleba anya ngwaahịa nke akụrụngwa ebuli laser

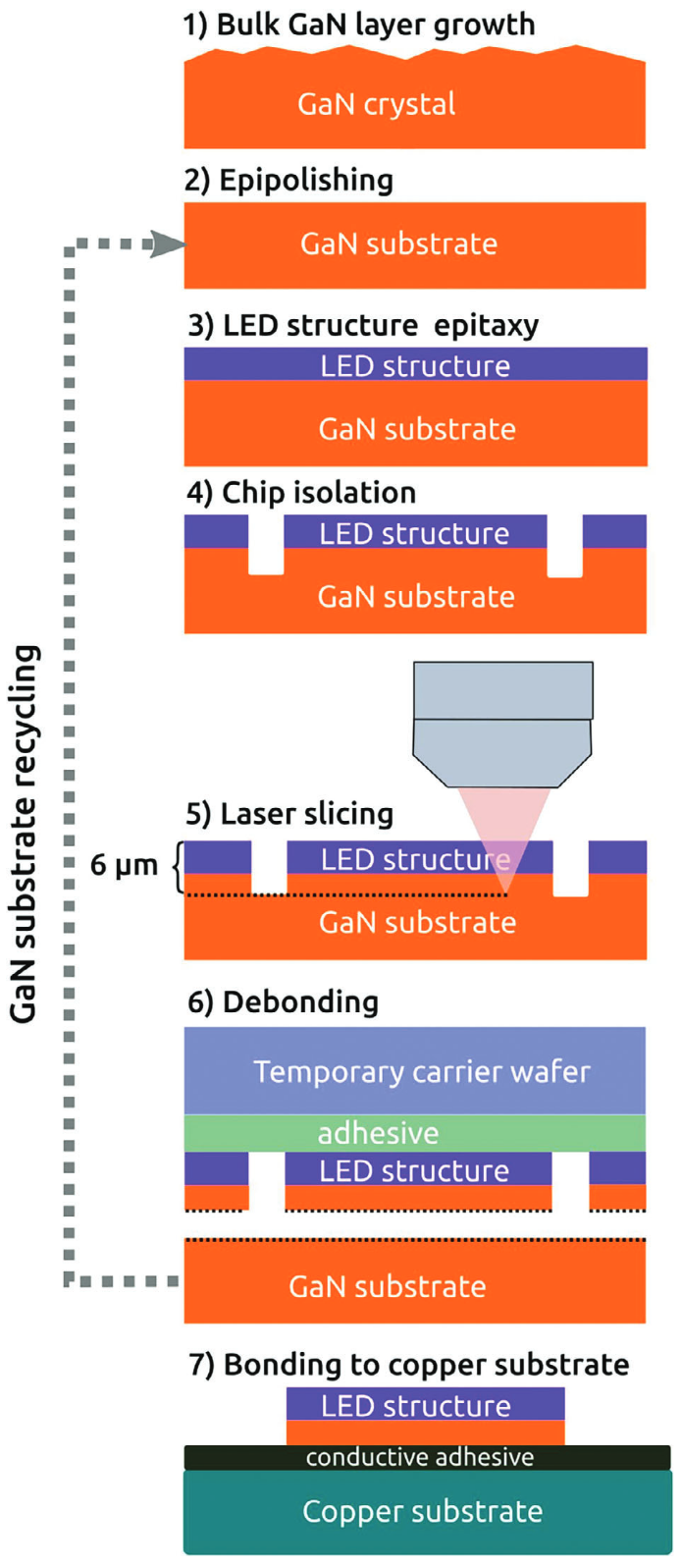

Ngwa ihe na-ebuli ihe laser nke Semiconductor na-anọchi anya ihe ngwọta ọgbọ na-abịa maka ingot thinning dị elu na nhazi ihe onwunwe semiconductor. N'adịghị ka ụzọ wafering ọdịnala na-adabere na igwe igwe, ịwa waya diamond, ma ọ bụ nhazi usoro nke kemịkalụ, ikpo okwu a na-adabere na laser na-enye ụzọ na-enweghị kọntaktị, nke na-adịghị emebi emebi maka iwepụ akwa dị nro site na nnukwu semiconductor ingots.

Ekebere maka ihe ndị na-agbaji agbaji na ihe ndị dị elu dị ka gallium nitride (GaN), silicon carbide (SiC), sapphire, na gallium arsenide (GaAs), Semiconductor Laser Lift-Off Equipment na-enyere aka nkenke nkenke nke ihe nkiri wafer ozugbo site na kristal ingot. Nkà na ụzụ ọganihu a na-ebelata nke ukwuu n'efu, na-eme ka mmepụta ya dịkwuo mma, ma na-akwalite iguzosi ike n'ezi ihe - ihe niile dị oke mkpa maka ngwaọrụ ndị na-abịa n'ihu na ngwa eletrọnịkị, sistemu RF, photonics, na obere ngosi.

Site n'ịgbasi ike na njikwa akpaaka, nhazi beam, na nyocha mmekọrịta ihe laser, Semiconductor Laser Lift-Off Equipment bụ nke e mere ka ọ banye n'enweghị nsogbu n'ime usoro mmepụta semiconductor mgbe ọ na-akwado mgbanwe R&D na oke mmepụta ihe.

Nkà na ụzụ & ụkpụrụ arụ ọrụ nke akụrụngwa ebuli ọkụ Laser

Usoro nke Semiconductor Laser Lift-Off Equipment na-arụ na-amalite site n'iji ọkụ ọkụ ọkụ ultraviolet dị elu mee ka onye na-enye onyinye pụta ìhè. A na-elekwasị anya nke ọma n'osisi a na omimi dị n'ime, ọ na-adịkarị n'akụkụ ihe eji arụ ọrụ arụrụ arụ, ebe a na-ebuli ike ike ya n'ihi ọdịiche anya, ọkụ, ma ọ bụ kemịkalụ.

N'elu oyi akwa mmịnye ike a, kpo oku mpaghara na-eduga na mgbawa obere ngwa ngwa, mgbasawanye gas, ma ọ bụ ire ere nke oyi akwa interfacial (dịka ọmụmaatụ, ihe nkiri nrụgide ma ọ bụ oxide ịchụàjà). Nke a na-achịkwa nke ọma na-akpata ọgba aghara na-akpata oyi akwa kristal dị elu - nke nwere oke iri iri nke micrometers - wepụ ya na ntọala ingot dị ọcha.

Ngwa Semiconductor Laser Lift-Off Equipment na-eme ka isi nyocha nke mmegharị mmegharị, njikwa z-axis mmemme, na reflectometry ozugbo iji hụ na usu ọ bụla na-enye ike kpọmkwem na ụgbọ elu ebumnuche. Enwere ike hazie akụrụngwa ahụ site na iji ụdị mgbawa ma ọ bụ ọtụtụ usu iji kwalite ịdị nro na-apụ apụ ma belata nrụgide fọdụrụnụ. Nke dị mkpa, n'ihi na ọkụ laser adịghị emetụta ihe ahụ n'ụzọ anụ ahụ, ihe ize ndụ nke microcracking, ịkpọ isiala, ma ọ bụ chipping elu na-ebelata nke ukwuu.

Nke a na-eme ka laser ebuli-apụ thinning usoro ihe egwuregwu na-agbanwe, karịsịa na ngwa ebe ultra-flat, ultra-thin wafers na sub-micron TTV (Mkpokọta ọkpụrụkpụ Mgbanwe).

Parameter nke ihe nrụpụta Laser Semiconductor

| Ogologo ogologo | IR/SHG/THG/FHG |

|---|---|

| Obosara Pulse | Nanosecond, Picosecond, Femtosecond |

| Sistemụ ngwa anya | Sistemụ ngwa anya edobere ma ọ bụ sistemu Galvano-optical |

| Oge XY | 500 mm × 500 mm |

| Oke nhazi | 160 mm |

| Ọsọ mmegharị | Kachasị 1,000 mm / sk |

| Nkwagharị ugboro ugboro | ± 1 μm ma ọ bụ obere |

| Izi ezi ọnọdụ zuru oke: | ± 5 μm ma ọ bụ obere |

| Nha wafer | 2–6 inch ma ọ bụ ahaziri |

| Njikwa | Windows 10,11 na PLC |

| Voltaji na-enye ike | AC 200 V ± 20 V, Otu oge, 50/60 kHz |

| Akụkụ Mpụga | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| Ibu | 1,000 n'arọ |

Ngwa ụlọ ọrụ nke akụrụngwa ebuli laser

Ngwa ihe na-ebuli ihe ọkụ Laser Semiconductor na-agbanwe ngwa ngwa ka esi akwado ihe n'ofe ọtụtụ ngalaba semiconductor:

- Ngwa ike GaN kwụ ọtọ nke akụrụngwa ebuli laser

Mwepụ nke ihe nkiri GaN-on-GaN dị obere site na nnukwu ingots na-enyere aka nhazi nhazi kwụ ọtọ na ijikwa ihe ndị dị oke ọnụ.

- SiC Wafer Thinning maka Ngwa Schottky na MOSFET

Na-ebelata okpokolo agba nke ngwaọrụ ka ọ na-echekwa atụmatụ mkpụrụ - nke dị mma maka ngwa elektrọnik na-agbanwe ngwa ngwa.

- Igwe ọkụ nke dabeere na sapphire na ihe ngosi nke akụrụngwa ebuli laser

Na-akwado ikewa nke ọma nke akwa ngwaọrụ site na sapphire boules iji kwado mmepụta micro-LED nke kachasi mkpa, na-ekpo ọkụ.

- III-V ihe eji arụ ọrụ nke akụrụngwa ebuli laser

Na-eme ka mwepu nke GaAs, InP, na AlGaN n'ígwé maka njikọta optoelectronic dị elu.

- Thin-Wafer IC na ihe mmetụta sensọ

Na-emepụta ọkwa dị mkpa na-arụ ọrụ maka ihe mmetụta nrụgide, accelerometers, ma ọ bụ photodiodes, ebe nnukwu bụ ihe mgbochi arụmọrụ.

- Eletrọnịkị na-agbanwe agbanwe na transperent

Na-akwado ihe ndị dị nro dị nro dabara adaba maka ngosipụta na-agbanwe agbanwe, sekit wearable, na windo smart transperent.

N'akụkụ nke ọ bụla n'ime mpaghara ndị a, Semiconductor Laser Lift-Off Equipment na-arụ ọrụ dị oke mkpa n'ịkwalite obere ihe, iji ihe eji eme ihe, na ime ka ọ dị mfe.

Ajuju a na-ajụkarị (FAQ) nke akụrụngwa ebuli laser

Q1: Gịnị bụ opekempe ọkpụrụkpụ m nwere ike nweta site na iji Semiconductor Laser Equipment?

A1:N'etiti 10-30 microns dabere na ihe onwunwe. Usoro a nwere ike iwepụta nsonaazụ dị ntakịrị site na nhazi ntọala.

Q2: Enwere ike iji nke a rie otutu wafers site na otu ingot?

A2:Ee. Ọtụtụ ndị ahịa na-eji usoro ebuli elu laser rụọ usoro mmịpụta nke ọtụtụ akwa dị mkpa site na otu ingot buru ibu.

Q3: Kedu ihe nchekwa nchekwa agụnyere maka ọrụ laser dị elu?

A3:Ihe mkpuchi klaasị 1, sistemu mgbachichi, ihe mkpuchi beam, na mkpọchi akpaghị aka bụ ọkọlọtọ.

Q4: Olee otú usoro a si tụnyere diamond waya saws na okwu nke na-eri?

A4:Ọ bụ ezie na capex mbụ nwere ike ịdị elu karịa, iwepụ laser na-ebelata oke ọnụ ahịa a na-eri, mmebi mkpụrụ, na usoro nhazi post - na-eweda mkpokọta ọnụ ahịa nke nwe (TCO) ogologo oge.

Q5: Usoro a ọ nwere ike iru 6-inch ma ọ bụ 8-inch ingots?

A5:Kpamkpam. Ikpo okwu na-akwado ihe ruru inch iri na abụọ nwere nkesa beam na otu nnukwu usoro ngagharị.

Gbasara anyị

XKH na-ahụ maka mmepe teknụzụ dị elu, mmepụta na ire nke enyo anya pụrụ iche na ihe kristal ọhụrụ. Ngwaahịa anyị na-eje ozi ngwa anya eletrọnịkị, ngwa eletrọnịkị ndị ahịa na ndị agha. Anyị na-enye ngwa anya sapphire, mkpuchi oghere ekwentị mkpanaaka, ceramics, LT, Silicon Carbide SIC, Quartz, na kristal semiconductor. Site na nka nka na akụrụngwa dị oke ọnụ, anyị na-eme nke ọma na nhazi ngwaahịa na-abụghị ọkọlọtọ, na-achọ ịbụ onye na-eduga optoelectronic ihe ụlọ ọrụ teknụzụ dị elu.