Dị ka ọgbọ nke atọ semiconductor ihe onwunwe,silicon carbide (SiC)otu kristal nwere atụmanya ngwa sara mbara n'ichepụta ngwa eletrọnịkị dị elu na ike dị elu. Nkà na ụzụ nhazi nke SiC na-arụ ọrụ dị mkpa n'ịmepụta ihe ndị dị elu dị elu. Edemede a na-ewebata ọnọdụ nyocha ugbu a na teknụzụ nhazi SiC ma na China ma na mba ofesi, na-enyocha ma na-atụnyere usoro nke ịkpụ, ichikota, na polishing usoro, yana ọnọdụ na wafer flatness na elu roughness. Ọ na-akọwakwa ihe ịma aka ndị dị na nhazi SiC wafer ma na-atụle ntụziaka mmepe n'ọdịnihu.

Silicon carbide (SiC)wafers bụ ihe ntọala dị mkpa maka ngwaọrụ semiconductor ọgbọ nke atọ ma jide nnukwu mkpa na ikike ahịa n'ọhịa dị ka microelectronics, elektrọn eletriki, na ọkụ semiconductor. N'ihi na kemgwucha elu ekweghị ekwe na chemical kwụsie ike nkeSiC otu kristal, Usoro nhazi semiconductor ọdịnala adịghị adabara kpamkpam maka igwe ha. Ọ bụ ezie na ọtụtụ ụlọ ọrụ mba ụwa emeela nyocha buru ibu na nhazi teknụzụ SiC na-achọ otu kristal, teknụzụ ndị dị mkpa na-edobe nzuzo nke ọma.

N'ime afọ ndị na-adịbeghị anya, China abawanyela mgbalị na mmepe nke SiC otu kristal ihe na ngwaọrụ. Otú ọ dị, ọganihu nke nkà na ụzụ ngwaọrụ SiC na mba ahụ ugbu a na-egbochi njedebe na teknụzụ nhazi na àgwà wafer. Ya mere, ọ dị mkpa ka China kwalite ikike nhazi SiC iji kwalite àgwà nke SiC otu kristal substrates ma nweta ngwa ngwa ha bara uru na mmepụta oke.

Usoro nhazi bụ isi gụnyere: ịcha → ihicha ihe na-esighi ike → mma egweri → polishing siri ike (mechanical polishing) → mma polishing (chemical mechanical polishing, CMP) → nyocha.

| Nzọụkwụ | SiC Wafer nhazi | Semiconductor Omenala Ọdịnala Nhazi Ihe Otu-Crystal |

| Ịcha | Na-eji teknụzụ ịwa ihe ọtụtụ waya iji kụrie ingots SiC n'ime obere wafer | A na-eji usoro ịkpụ agụba dị n'ime-dayamita ma ọ bụ n'èzí |

| Na-egweri | Kewara n'ime nnukwu ihe na-egweri dị mma iji wepụ akara ịkwọ ụgbọala na mmebi n'ígwé kpatara ọnwụ | Ụzọ egweri nwere ike ịdịgasị iche, mana ebumnuche bụ otu |

| Nchacha | Gụnyere polishing siri ike na nkenke nkenke site na iji igwe na kemịkalụ polishing (CMP) | Ọ na-agụnyekarị polishing mechanical polishing (CMP), n'agbanyeghị usoro ụfọdụ nwere ike ịdị iche |

Ịcha SiC Single kristal

Na nhazi nkeSiC otu kristal, igbubi bụ nzọụkwụ mbụ na nke dị oke egwu. Ụta wafer, warp, na mkpokọta ọkpụrụkpụ dị iche (TTV) sitere na usoro igbutu na-ekpebi ịdịmma na ịdị irè nke ịhịarị na nchacha na-esote.

Enwere ike ịhazi ngwaọrụ ịcha ihe site na udi ka ọ bụrụ nkwọ diamond n'ime dayameta (ID), nkwọ n'elu dayameta (OD), nkwọ band, na waya. N'aka nke ya, enwere ike ịkewa nkwọ waya site n'ụdị ngagharị ha n'ime usoro waya na-emegharị emegharị na loop (na-adịghị agwụ agwụ). Dabere na usoro ịkpụ nke abrasive, waya hụrụ slicing usoro nwere ike kewaa ụzọ abụọ: free abrasive waya sawing na ofu abrasive diamond waya sawing.

1.1 Ụzọ ịkpụ omenala

Omimi mbelata nke mpụta dayameta (OD) saws na-ejedebe site na dayameta nke agụba. N'oge usoro ịkpụ, agụba ahụ na-enwekarị ịma jijiji na ntụgharị, na-eme ka ụda ụda dị elu na adịghị ike. Dayameta dị n'ime (ID) saws na-eji abrasives diamond n'okirikiri ime nke agụba ahụ dị ka mbepụ. Ube ndị a nwere ike ịdị gịrịgịrị dịka 0.2 mm. N'oge slicing, agụba ID na-atụgharị n'ọsọ dị elu ebe ihe a ga-egbutu na-aga n'ihu na etiti agụba ahụ, na-enweta slicing site na mmegharị nke a.

Nkwọ diamond na-achọ nkwụsị na ntụgharị ugboro ugboro, na ịcha ọsọ dị oke ala-na-adịkarịghị 2 m / s. Ha na-atakwa ahụhụ n'ihi oke nrụnye igwe na ọnụ ahịa mmezi dị elu. N'ihi obosara nke agụba a na-ahụ anya, radius ịkpụ enweghị ike ịdị ntakịrị, na ịcha ọtụtụ ihe agaghị ekwe omume. Ngwá ọrụ ịwa osisi ọdịnala ndị a nwere oke site na nkwụsi ike nke isi na enweghị ike ịme mkpụkọ mkpụkọ ma ọ bụ machibido radis ntụgharị. Ha na-enwe ike igbubi ogologo oge, na-emepụta kerfs sara mbara, na-enwe obere mkpụrụ, ma si otú a na-adịghị mma maka ịkpụ.SiC kristal.

1.2 Waya abrasive efu hụrụ n'ịcha ọtụtụ waya

The free abrasive waya usoro slicing usoro na-eji ngwa ngwa ije nke waya na-ebu slurry n'ime kerf, na-enyere mwepụ ihe onwunwe. Ọ na-eji usoro nkwụghachi ụgwọ ma ugbu a bụ usoro tozuru oke na nke a na-ejikarị eme ihe maka ịkpụcha ọtụtụ wafer nke silicon silicon. Agbanyeghị, ngwa ya na ịkpụ SiC amụbeghị nke ọma.

Nkwọ waya abrasive efu nwere ike hazie wafer na ọkpụrụkpụ na-erughị 300 μm. Ha na-enye mfu kerf dị ala, ọ na-adịkarịghị ebute chipping, ma na-ebute ọdịdị elu dịtụ mma. Otú ọ dị, n'ihi usoro mwepụ ihe onwunwe-dabere na ntugharị na ntinye nke abrasives-elu wafer na-eme ka nrụgide fọdụrụnụ pụta ìhè, microcracks, na akwa mmebi dị omimi. Nke a na-eduga na wafer warping, na-eme ka o sie ike ịchịkwa izi ezi nke profaịlụ elu, ma na-abawanye ibu na usoro nhazi na-esote.

A na-enwe mmetụta dị ukwuu site na slurry nke ịkpụ arụ ọrụ; ọ dị mkpa iji nọgide na-adị nkọ nke abrasives na ntinye nke slurry. Ọgwụgwọ slurry na imegharị ihe na-efu ọnụ. Mgbe ị na-egbutu ingots buru ibu, abrasives na-esiri ike ịbanye n'ime kerfs miri emi na ogologo. N'okpuru otu nha ọka abrasive ahụ, mfu kerf dị ukwuu karịa nke nkwọ waya na-akpachapụ anya.

1.3 Akara abrasive diamond waya hụrụ ọtụtụ waya ịcha

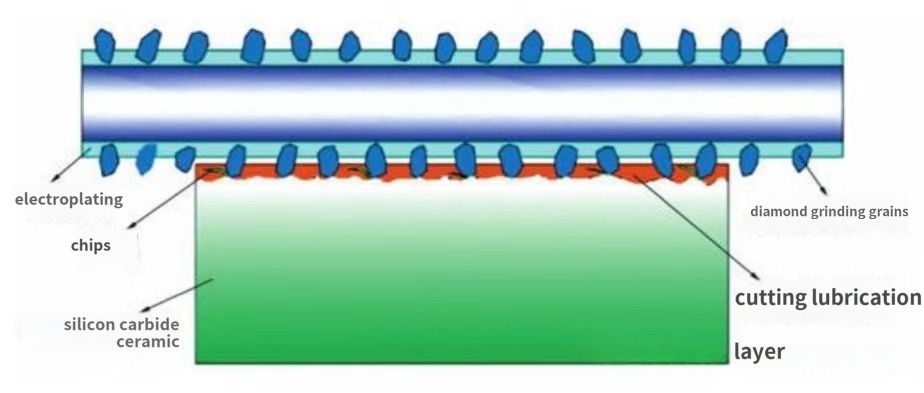

A na-ejikarị eriri diamond abrasive abrasive abrasive emebere site n'itinye irighiri diamond n'ime eriri igwe site na iji electroplating, sintering, ma ọ bụ resin bonding. Nkịta waya diamond eletrọnịlụ na-enye uru dị ka kerfs dị warara, ịdị mma iberi ka mma, arụmọrụ dị elu, mmetọ dị ala, yana ikike igbutu ihe ndị siri ike.

Igwe waya diamond na-emegharịghachi azụ bụ usoro a kacha eji egbutu SiC ugbu a. Ọgụgụ 1 (egosighi ebe a) na-egosi mbelata elu nke SiC wafers ịkpụ site na iji usoro a. Ka igbutu na-aga n'ihu, wafer warpage na-abawanye. Nke a bụ n'ihi na mpaghara kọntaktị dị n'etiti waya na ihe na-abawanye ka waya na-aga n'ihu, na-abawanye nguzogide na ịma jijiji waya. Mgbe waya ruru oke dayameta nke wafer, ịma jijiji dị na ọnụ ọgụgụ ya, na-ebute oke agha.

N'oge ikpeazụ nke ịkpụ, n'ihi waya na-eme ngwa ngwa, mmegharị ọsọ ọsọ, nkwụsịtụ, nkwụsị na ntụgharị, yana ihe isi ike na-ewepụ ihe mkpofu na coolant, ọdịdị elu nke wafer na-akawanye njọ. Ntugharị waya na mgbanwe ọsọ ọsọ, yana nnukwu irighiri diamond na waya, bụ isi ihe na-ebute ncha n'elu.

1.4 Teknụzụ nkewa oyi

Nkewa oyi nke otu kristal SiC bụ usoro ọhụrụ n'ọhịa nke nhazi ihe semiconductor nke ọgbọ nke atọ. N'afọ ndị na-adịbeghị anya, ọ dọtala nlebara anya dị ukwuu n'ihi uru ndị pụtara ìhè n'ịkwalite mkpụrụ na ibelata mfu ihe. Enwere ike nyochaa teknụzụ site na akụkụ atọ: ụkpụrụ ọrụ, usoro nhazi, na uru ndị bụ isi.

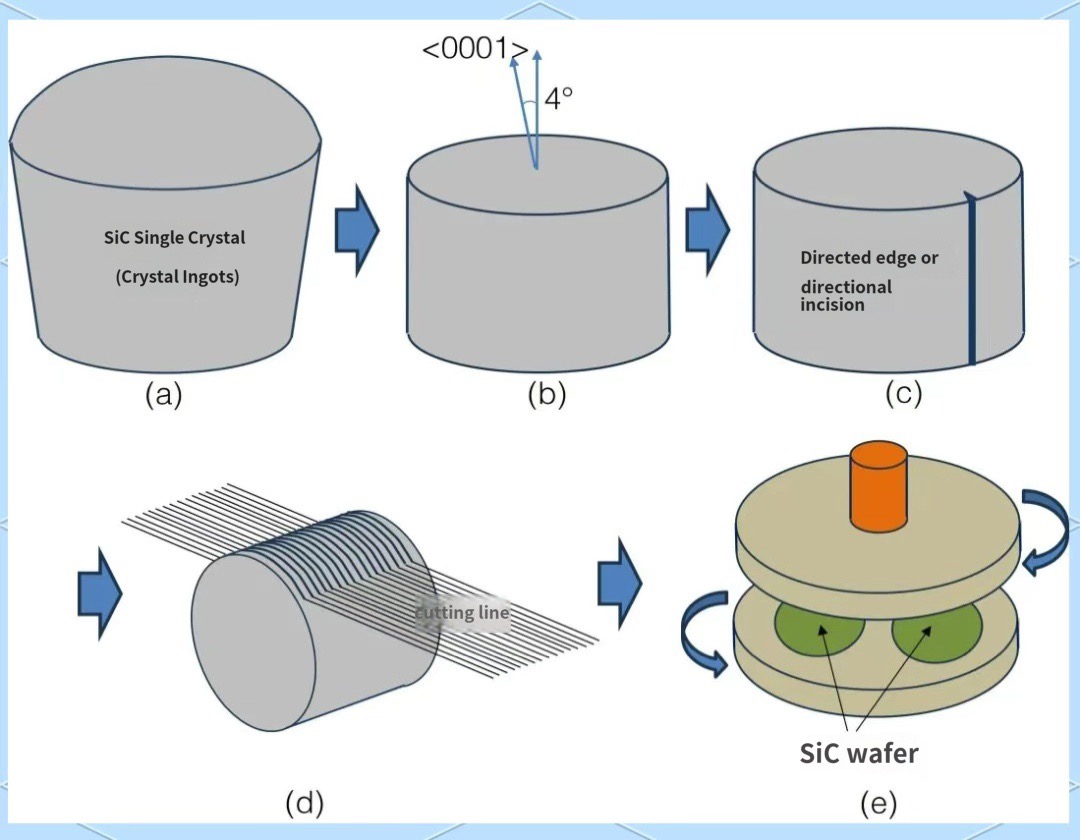

Mkpebi Orientation Crystal na Mpụ Ọdịda Anyanwụ: Tupu nhazi, nghazi kristal nke SiC ingot ga-ekpebirịrị. A na-akpụzi ingot ahụ ka ọ bụrụ usoro cylindrical (nke a na-akpọkarị SiC puck) site na igwe dayameta dị n'elu. Nzọụkwụ a na-atọ ntọala maka ịkpụ na slicing ntụziaka na-esote.

Multi-Wire Cutting: Usoro a na-eji ihe abrasive jikọtara ya na ịcha waya iji kụrie ingot cylindrical. Agbanyeghị, ọ na-enwe nnukwu mfu kerf yana nsogbu enweghị isi.

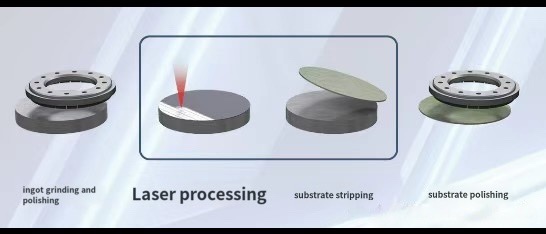

Laser Cutting Technology: A na-eji laser na-emepụta oyi akwa gbanwetụrụ n'ime kristal, nke a ga-esi na ya wepụ mpekere ndị dị mkpa. Ụzọ a na-ebelata ihe onwunwe na-efunahụ ma na-eme ka nhazi nhazi dị mma, na-eme ka ọ bụrụ ntụziaka ọhụrụ na-ekwe nkwa maka ịkpụ SiC wafer.

Nkwalite usoro ịkpụcha

Edobere Abrasive Multi-Wire Cutting: Nke a bụ teknụzụ bụ isi ugbu a, dabara nke ọma maka njirimara siri ike nke SiC.

Igwe ọkụ eletrik (EDM) na teknụzụ nkewa oyi: Ụzọ ndị a na-enye ngwọta dịgasị iche iche ahaziri maka ihe achọrọ.

Usoro nchacha: Ọ dị mkpa iji dozie ọnụego mwepụ ihe onwunwe na mmebi elu. A na-eji ihe nrụnye kemịkalụ (CMP) rụọ ọrụ iji kwalite ịdị n'otu.

Nleba anya n'ezie: ewebata teknụzụ nyocha n'ịntanetị iji nyochaa ịdị njọ nke elu n'oge.

Laser Slicing: Usoro a na-ebelata mfu kerf ma na-ebelata usoro nhazi oge, n'agbanyeghị na mpaghara okpomọkụ emetụtara ka bụ ihe ịma aka.

Teknụzụ nhazi ngwakọ: Ijikọta usoro n'ibu na kemịkalụ na-eme ka arụmọrụ nhazi dị mma.

Teknụzụ a enwetala ngwa ụlọ ọrụ mmepụta ihe. Dịka ọmụmaatụ, Infineon nwetara SILTECTRA ma jidezi patent ndị na-akwado mmepụta oke nke 8-inch wafers. Na China, ụlọ ọrụ dị ka Delong Laser enwetala nrụpụta nrụpụta nke 30 wafers kwa ingot maka nhazi wafer 6 inch, na-anọchite anya nkwalite 40% karịa usoro ọdịnala.

Ka nrụpụta akụrụngwa ụlọ na-agba ọsọ ọsọ, a na-atụ anya na teknụzụ a ga-abụ isi ihe ngwọta maka nhazi mkpụrụ osisi SiC. Site na dayameta na-arịwanye elu nke ihe semiconductor, ụzọ ịcha ihe ọdịnala aghọwo ihe na-adịghịzi adị. N'ime nhọrọ ndị dị ugbu a, teknụzụ diamond na-emegharị ọnụ na-egosi atụmanya ngwa kachasị mma. Ịcha laser, dị ka usoro na-apụta, na-enye uru dị ukwuu ma na-atụ anya na ọ ga-abụ usoro ịkpụ isi n'ọdịnihu.

2,SiC Single Crystal egweri

Dị ka onye nnọchiteanya nke ọgbọ nke atọ semiconductors, silicon carbide (SiC) na-enye uru dị ukwuu n'ihi nnukwu bandgap ya, oke ọkụ eletrik dị elu, elu saturation electron drift velocity, na ezigbo ọkụ ọkụ. Ngwongwo ndị a na-eme ka SiC bara uru na ngwa voltaji dị elu (dịka, gburugburu 1200V). Teknụzụ nhazi maka ihe ndị SiC bụ akụkụ bụ isi nke imepụta ngwaọrụ. Ogo elu na nkenke nke mkpụrụ osisi na-emetụta àgwà nke oyi akwa epitaxial na arụmọrụ nke ngwaọrụ ikpeazụ.

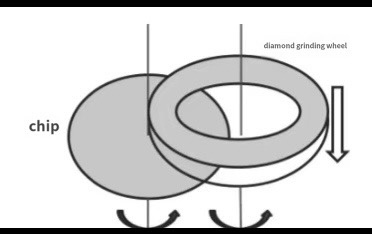

Nzube bụ isi nke usoro egweri bụ iwepụ akara nhụsịrị elu na nbibi n'ígwé ndị kpatara n'oge slicing, na imezi nrụrụ nke usoro ịkpụ ahụ kpatara. Nyere SiC siri ike nke ukwuu, egweri chọrọ iji abrasives siri ike dị ka boron carbide ma ọ bụ diamond. A na-ekewakarị egweri egweri gaa n'igwe ọka na-egweri nke ọma.

2.1 Ọkpụkpụ na nke ọma

Enwere ike ịha nha-egweri dabere na nha urughuru abrasive:

Ichicha akwa: na-eji abrasives buru ibu na-ebu ụzọ wepụ akara nkwọ na akwa akwa mebiri n'oge slicing, na-emeziwanye nhazi nhazi.

Egweri dị mma: Na-eji abrasives ka mma wepụ oyi akwa mebiri site n'igwe ọka siri ike hapụrụ, belata adịghị ike nke elu, ma welie ogo elu.

Ọtụtụ ndị na-emepụta mkpụrụ osisi SiC na-eji usoro mmepụta buru ibu. Usoro a na-ahụkarị gụnyere iji efere ígwè nkedo na monocrystalline diamond slurry egweri akụkụ abụọ. Usoro a na-ewepụ nke ọma oyi akwa mebiri site n'ịwa waya, na-edozi ọdịdị wafer, ma na-ebelata TTV (Total Thickness Variation), ụta, na Warp. Ọnụego mwepụ ihe onwunwe kwụsiri ike, na-erukarị 0.8-1.2 μm/min. Otú ọ dị, n'elu wafer na-esi na ya pụta bụ matte nwere oke siri ike-nke dị gburugburu 50 nm-nke na-etinye ihe ndị dị elu na usoro nhazi nke na-esote.

2.2 Egweri otu akụkụ

Usoro egweri otu akụkụ naanị otu akụkụ nke wafer n'otu oge. N'oge usoro a, a na-etinye wafer ahụ n'elu efere ígwè. N'okpuru nrụgide etinyere, mkpụrụ ahụ na-enweta ntakịrị nrụrụ, na elu elu na-agbada. Mgbe egwerichara, a na-edozi elu ala. Mgbe a na-ewepụ nrụgide ahụ, elu elu ahụ na-agbakeghachi n'ụdị mbụ ya, nke na-emetụtakwa ala ala ala-na-eme ka akụkụ abụọ ahụ na-adaba ma na-eweda n'ala dị larịị.

Ọzọkwa, efere egweri nwere ike ịghọ concave n'ime obere oge, na-eme ka wafer ahụ ghọọ convex. Iji nọgide na-adị larịị nke efere ahụ, a chọrọ mgbakwasa ugboro ugboro. N'ihi arụmọrụ dị ala na adịghị mma wafer flatness, egweri otu akụkụ adịghị adabara maka mmepụta oke.

A na-eji #8000 wiil egweri eme ihe nke ọma. Na Japan, usoro a ka tozuru oke ma na-eji wiilị #30000 eme ihe. Nke a na-enye ohere ịdị elu nke wafers ndị a na-eme ka ọ dị n'okpuru 2 nm, na-eme ka wafers dị njikere maka CMP ikpeazụ (Chemical Mechanical Polishing) na-enweghị nhazi ọzọ.

2.3 Nkà na ụzụ Thinning otu akụkụ

Teknụzụ Thinning Single-Sided Diamond bụ usoro ọhụrụ nke egweri otu akụkụ. Dị ka e gosiri na foto 5 (anaghị egosi ebe a), usoro a na-eji efere egweri nke jikọtara diamond. A na-edozi wafer site na mgbasa ozi agụụ, ebe ma wafer na wiil igwe diamond na-atụgharị n'otu oge. Ụkwụ egweri nke nta nke nta na-aga ala iji mee ka wafer ahụ dị nro ruo n'obosara ebumnuche. Ka emechara otu akụkụ, a na-atụgharị wafer ahụ iji hazie akụkụ nke ọzọ.

Mgbe ịchachara, wafer 100 mm nwere ike nweta:

Ụta <5 μm

TTV <2 μm

Ọkpụkpụ elu <1 nm

Usoro nhazi nke otu wafer a na-enye nkwụsi ike dị elu, nkwụsi ike dị mma, na oke mwepụ ihe onwunwe. E jiri ya tụnyere ịhịhịa akụkụ abụọ a na-emekarị, usoro a na-eme ka arụmọrụ egweri karịa 50%.

2.4 Egweri akụkụ abụọ

Egweri akụkụ abụọ na-eji ma nke elu na nke ala ala na-egweri n'otu oge n'akụkụ abụọ nke mkpụrụ ahụ, na-eme ka ọdịdị elu dị mma n'akụkụ abụọ ahụ.

N'oge usoro ahụ, efere ndị na-egweri na-ebu ụzọ tinye nrụgide na isi ihe kachasị elu nke workpiece, na-eme ka nrụrụ na iwepụ ihe eji nwayọọ nwayọọ na ebe ndị ahụ. Ka a na-agbatị ebe ndị dị elu, nrụgide dị na mkpụrụ osisi ahụ na-eji nwayọọ nwayọọ na-agbanwe agbanwe, na-ebute nrụrụ na-agbanwe agbanwe n'ofe dum. Nke a na-enye ohere ma elu na elu ala ka ọ bụrụ ala nke ọma. Ozugbo egweri egweri ma hapụ nrụgide ahụ, akụkụ nke ọ bụla nke mkpụrụ ahụ na-agbake n'otu n'otu n'ihi nrụgide nha anya ọ nwetara. Nke a na-eduga na obere warping na mma flatness.

Ọdịdị dị elu nke wafer mgbe egwerichara na-adabere na nha urughuru abrasive-obere irighiri ihe na-emepụta ebe dị nro. Mgbe ị na-eji 5 μm abrasives maka egweri akụkụ abụọ, wafer flatness na ọkpụrụkpụ dị iche nwere ike ịchịkwa n'ime 5 μm. Atomic Force Microscope (AFM) nha na-egosi nhụsianya elu (Rq) nke ihe dịka 100 nm, na-egweri olulu ruo 380 nm miri emi na akara ahịrị ahịrị a na-ahụ anya nke abrasive mere.

Ụzọ dị elu ka ukwuu gụnyere ichikota akụkụ abụọ site na iji polyurethane foam pads jikọtara ya na polycrystalline diamond slurry. Usoro a na-emepụta wafers na oke ala dị ala, na-enweta Ra <3 nm, nke bara uru nke ukwuu maka ịchachasị ihe ndị SiC na-esote.

Agbanyeghị, ịcha n'elu ka bụ ihe edozibeghị. Tụkwasị na nke a, a na-emepụta diamond polycrystalline nke a na-eji eme ihe na usoro a site na mgbawa mgbawa, nke na-eme ka nkà na ụzụ sie ike, na-emepụta ọnụ ọgụgụ dị ala ma dị oke ọnụ.

Nchacha nke SiC Single Crystals

Iji nweta elu dị elu na-egbu maramara na silicon carbide (SiC) wafers, polishing ga-ewepụ kpamkpam olulu na-egweri na nanometer-oke elu undulations. Ebumnuche bụ imepụta elu dị larịị, enweghị ntụpọ na-enweghị mmetọ ma ọ bụ nbibi, enweghị mmebi nke dị n'okpuru ala, na enweghị nrụgide elu.

3.1 Mechanical Polishing na CMP nke SiC Wafers

Mgbe uto nke ingot otu SiC kristal, ntụpọ dị n'elu na-egbochi iji ya mee ihe ozugbo maka uto epitaxial. Ya mere, a chọrọ nhazi ọzọ. A na-ebu ụzọ kpụzie ingot ka ọ bụrụ ụdị cylindrical ọkọlọtọ site na ịgbagharị, wee kpaa ya n'ime wafer site na iji ịkpụ waya, na-esote nkwenye nghazi kristal. Ntucha bụ nzọụkwụ dị oke mkpa n'ịkwalite ogo wafer, na-eleba anya na mmebi elu nwere ike ịkpata site na ntụpọ uto kristal na usoro nhazi tupu oge eruo.

Enwere ụzọ anọ bụ isi maka iwepu akwa mmebi elu na SiC:

Mechanical polishing: Mfe ma doo ọkọ; adabara maka mbụ polishing.

Ntucha igwe kemịkalụ (CMP): na-ewepụ ncha site na etching kemịkal; adabara nkenke polishing.

Hydrogen etching: chọrọ akụrụngwa mgbagwoju anya, nke a na-ejikarị na usoro HTCVD.

Nchacha enyere aka Plasma: Mgbagwoju anya na adịkarịghị eji.

Nchacha naanị n'ọrụ igwe na-ebute ọkpụkpụ, ebe ịchacha naanị kemịkalụ nwere ike ibute etching na-ezighi ezi. CMP na-ejikọta ma uru abụọ ahụ ma na-enye ngwọta dị mma, dị ọnụ ahịa.

Ụkpụrụ ọrụ CMP

CMP na-arụ ọrụ site n'ịtụgharị wafer n'okpuru nrụgide setịpụrụ megide mpe mpe akwa na-atụgharị. Ntugharị ikwu nke a, jikọtara ya na abrasion n'ibu sitere na nano-sized abrasives na slurry na mmetụta kemịkalụ nke ndị na-emeghachi omume, na-enweta nhazi elu.

Isi ihe eji:

slurry na-ekpochapụ: Nwere abrasives na reagents kemịkalụ.

Mpempe akwụkwọ na-ehicha ihe: Ọ na-adị ala mgbe a na-eji ya eme ihe, na-ebelata ogo pore na arụmọrụ nnyefe slurry. A chọrọ iyi uwe mgbe niile, na-ejikarị akwa diamond, iji weghachi ike.

Usoro CMP a na-ahụkarị

Abrasive: 0.5 μm diamond slurry

Ebube n'elu ebumnuche: ~ 0.7 nm

Nchacha igwe kemịkalụ:

Akụrụngwa polishing: AP-810 polisher otu akụkụ

Nrụgide: 200 g/cm²

Ọsọ efere: 50 rpm

Ọsọ ihe njide seramiki: 38 rpm

Ngwakọta slurry:

SiO₂ (30 wt%, pH = 10.15)

0–70 wt% H₂O₂ (30 wt%, akara reagent)

Gbanwee pH na 8.5 site na iji 5 wt% KOH na 1 wt% HNO₃

Ọnụego mgbaba slurry: 3 l/min, ekegharịrị

Usoro a na-eme ka mma SiC wafer dị mma ma mezuo ihe achọrọ maka usoro mgbada.

Ihe ịma aka nka na ụzụ na polishing igwe

SiC, dị ka semiconductor bandgap sara mbara, na-arụ ọrụ dị mkpa na ụlọ ọrụ eletrọnịkị. N'ịbụ ndị nwere ezigbo anụ ahụ na kemịkal dị mma, otu kristal SiC dabara adaba maka gburugburu ebe dị oke egwu, dị ka oke okpomọkụ, ugboro dị elu, ike dị elu, na nguzogide radieshon. Otú ọ dị, ọdịdị ya siri ike na nke na-esighi ike na-enye nnukwu ihe ịma aka maka ichicha na ihicha.

Dị ka ndị na-eduzi ndị na-emepụta ụwa na-agbanwe site na 6-inch gaa na 8-inch wafers, okwu ndị dị ka mgbawa na mmebi wafer n'oge nhazi aghọwo ihe a ma ama, na-emetụta mkpụrụ. Ịkwado ihe ịma aka teknuzu nke 8-inch SiC substrates bụ ugbu a bụ isi akara maka ọganihu ụlọ ọrụ ahụ.

N'ime oge inch 8, nhazi SiC wafer na-eche ọtụtụ ihe ịma aka ihu:

Ntugharị wafer dị mkpa iji mụbaa mmepụta mgbawa n'otu ogbe, belata mfu n'ọnụ, yana ọnụ ahịa nrụpụta dị ala-karịsịa nyere ịrị elu nke ngwa ụgbọ ala eletrik.

Ọ bụ ezie na uto nke 8-inch SiC otu kristal torola, usoro azụ azụ dị ka egweri na polishing ka na-eche ihe mgbochi ihu, na-ebute obere mkpụrụ (naanị 40-50%).

Wafer ndị buru ibu na-enweta nkesa nrụgide dị mgbagwoju anya karị, na-abawanye ihe isi ike nke ijikwa nrụgide na-egbuke egbuke ma na-amịpụta nkwụsi ike.

Ọ bụ ezie na ọkpụrụkpụ nke 8-inch wafer na-abịaru nso nke 6-inch wafers, ha na-adịkarị mfe imebi n'oge njikwa n'ihi nrụgide na agha.

Iji belata mgbakasị ahụ metụtara mbelata, warpage, na mgbawa, a na-ejiwanye ịkpụ laser. Agbanyeghị:

Laser na-ewe ogologo oge na-akpata mmebi okpomọkụ.

Igwe laser dị mkpụmkpụ na-ewepụta ihe mkpofu dị arọ ma mee ka oyi akwa mebiri emebi na-abawanye, na-abawanye mgbagwoju anya.

Usoro nhazi igwe maka SiC

Usoro usoro izugbe gụnyere:

Ịcha nhazi

Egweri siri ike

Egweri nke ọma

Mechanical polishing

Chemical Mechanical Polishing (CMP) dị ka nzọụkwụ ikpeazụ

Nhọrọ nke usoro CMP, nhazi ụzọ usoro, na njikarịcha nke paramita dị oke mkpa. N'imepụta semiconductor, CMP bụ mkpebi ikpebi maka imepụta wafers SiC nwere ọmarịcha, enweghị ntụpọ, na enweghị mmebi, nke dị mkpa maka uto epitaxial dị elu.

(a) Wepu ingot SiC na crucible;

(b) Mee nhazi mbụ site n'iji egweri elu elu;

(c) Kpebie nghazi kristal site na iji steetị ma ọ bụ ọkwa ọkwa;

(d) Iberibe ihe ingot n'ime obere wafer site na iji ịwa osisi ọtụtụ waya;

(e) Nweta ire ụtọ elu dị ka enyo site n'igweri na nchacha nzọụkwụ.

Mgbe emechara usoro nhazi usoro, nsọtụ mpụta nke SiC wafer na-abụkarị nkọ, nke na-abawanye ohere nke chipping n'oge njikwa ma ọ bụ ojiji. Iji zere adịghị ike dị otú ahụ, a chọrọ ka egweri ihu.

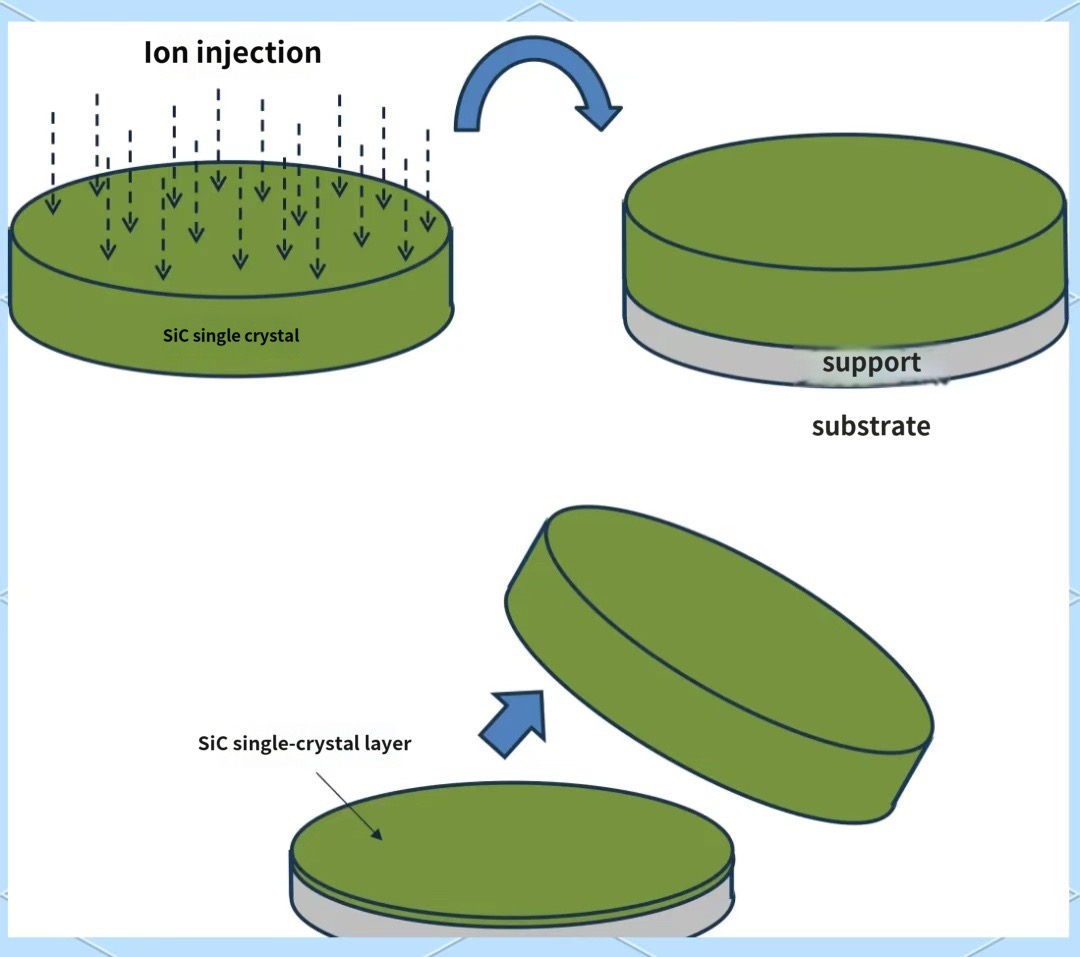

Na mgbakwunye na usoro slicing ọdịnala, usoro ọhụrụ maka ịkwadebe wafer SiC gụnyere teknụzụ njikọ. Ụzọ a na-enyere aka imepụta wafer site na ijikọta otu oyi akwa SiC dị obere na mkpụrụ osisi dị iche iche (mkpụrụ na-akwado).

Ihe osise 3 na-egosi usoro nke usoro:

Nke mbụ, a na-emepụta oyi akwa delamination na omimi akọwapụtara n'elu nke otu kristal SiC site na ntinye hydrogen ion ma ọ bụ usoro ndị yiri ya. Otu kristal SiC emeziri na-ejikọta ya na mkpụrụ na-akwado larịị ma tinye ya na nrụgide na okpomọkụ. Nke a na-enye ohere mbufe na nkewa nke otu-crystal oyi akwa SiC n'ime mkpụrụ na-akwado nke ọma.

Oghere SiC kewapụrụ iche na-enweta ọgwụgwọ elu iji nweta ịdị larịị achọrọ ma enwere ike ijikwa ya na usoro njikọ na-esote. E jiri ya tụnyere slicing omenala nke kristal SiC, usoro a na-ebelata ọchịchọ maka ihe ndị dị oke ọnụ. Ọ bụ ezie na ihe ịma aka teknuzu ka dị, nyocha na mmepe na-aga n'ihu nke ọma iji mee ka mmepụta wafer dị ọnụ ala.

Nyere akwa siri ike na nkwụsi ike kemịkalụ nke SiC-nke na-eme ka ọ bụrụ ihe na-eguzogide mmeghachi omume n'ime ụlọ okpomọkụ-a chọrọ polishing igwe iji wepụ olulu ndị na-egweri nke ọma, belata mmebi elu, wepụ ihe ncha, pitting, na peel peel peel, nke dị ala ala, melite flatness, na ịkwalite mma elu.

Iji nweta elu na-egbuke egbuke dị elu, ọ dị mkpa:

Gbazie ụdị abrasive,

Belata nha urughuru,

Welie paramita usoro,

Họrọ ihe na-egbuke egbuke na pads nwere ike siri ike zuru oke.

Ọgụgụ 7 na-egosi na polishing akụkụ abụọ na 1 μm abrasives nwere ike ịchịkwa flatness na ọkpụrụkpụ mgbanwe n'ime 10 μm, na ibelata elu roughness na banyere 0.25 nm.

3.2 Chemical Mechanical Polishing (CMP)

Chemical Mechanical Polishing (CMP) na-ejikọta ultrafine urughuru abrasion na etching kemịkal na-etolite n'elu ihe a na-edozi nke ọma. Ụkpụrụ bụ isi bụ:

Mmeghachi omume kemịkalụ na-apụta n'etiti slurry na-egbuke egbuke na elu wafer, na-akpụ akwa dị nro.

Esemokwu dị n'etiti ihe abrasive na oyi akwa dị nro na-ewepụ ihe ahụ.

Uru CMP:

Na-emeri ihe ndọghachi azụ nke nchacha igwe ma ọ bụ kemịkal,

Na-enweta atụmatụ nhazi nke ụwa na nke mpaghara,

Na-emepụta elu na elu flatness na ala siri ike,

Ahapụghị elu ma ọ bụ n'okpuru ala mmebi.

Na nkowa:

The wafer na-akpali ikwu na polishing mpe mpe akwa n'okpuru nrụgide.

Abrasives nha nha nanometer (dịka, SiO₂) na slurry na-ekere òkè n'ịkpụcha ajị, na-eme ka njikọ ndị covalent Si–C daa ma na-akwalite mwepụ ihe onwunwe.

Ụdị usoro CMP:

Abrasive Polishing efu: Abrasives (dịka, SiO₂) na-akwụsịtụ na slurry. Mwepụ ihe na-apụta site na abrasion nke akụkụ atọ (wafer-pad-abrasive). Nha abrasive (nke na-abụkarị 60-200 nm), pH, na okpomọkụ ga-enwerịrị nke ọma ịchịkwa iji kwalite otu.

Edozi Abrasive Polishing: Abrasives na-agbakwunyere na pad na-egbuke egbuke iji gbochie agglomeration-dị mma maka nhazi dị elu.

Nchacha mgbe emechara:

A na-enweta wafers na-egbuke egbuke:

Nhicha kemịkalụ (gụnyere mmiri DI na mkpochapụ slurry),

DI mmiri rinsing, na

Na-ekpo ọkụ nitrogen ihicha

iji belata ihe ndị na-emerụ emerụ n'elu.

Ogo elu & Arụmọrụ

Enwere ike ibelata ịdị njọ nke elu ka ọ bụrụ Ra <0.3 nm, na-ezute ihe ndị chọrọ epitaxy semiconductor.

Planarization zuru ụwa ọnụ: Nchikota kemịkalụ nro na mwepu igwe na-ebelata ncha na etching na-ezighi ezi, na-arụpụta ụzọ igwe ma ọ bụ kemịkal dị ọcha.

Ịrụ ọrụ dị elu: Kwesịrị ekwesị maka ihe siri ike na nke na-adịghị ike dị ka SiC, yana ọnụego mwepụ ihe karịrị 200 nm / h.

Usoro nchacha ndị ọzọ na-apụta

Na mgbakwunye na CMP, atụpụtala ụzọ ndị ọzọ, gụnyere:

Electrochemical polishing,Catalyst-enyere aka polishing ma ọ bụ etching, na

Tribochemical polishing.

Agbanyeghị, ụzọ ndị a ka nọ n'ọkwa nyocha wee mepụta nwayọ nwayọ n'ihi njirimara akụrụngwa siri ike nke SiC.

N'ikpeazụ, nhazi SiC bụ usoro nwayọọ nwayọọ nke ibelata warpage na adịghị ike iji melite ogo elu, ebe nkwụsịtụ na njikwa ike dị oke mkpa n'oge ọ bụla.

Nkà na ụzụ nhazi

N'oge a na-egweri wafer, a na-eji slurry diamond nwere nha dị iche iche iji gwerie wafer ahụ ka ọ dị larịị achọrọ na ịdị nro dị elu. Nke a na-esochi polishing, na-eji ma igwe na nke kemịkalụ polishing (CMP) usoro iji mepụta wafer silicon carbide (SiC) enweghị mmebi.

Mgbe ihichachara, ndị SiC wafers na-enyocha ezigbo mma site na iji ngwa dị ka microscopes anya na X-ray diffractometers iji hụ na paramita teknụzụ niile ruru ụkpụrụ achọrọ. N'ikpeazụ, a na-ehicha wafer a na-egbu maramara site na iji ihe nhicha pụrụ iche na mmiri ultrapure iji wepụ ihe ndị na-emerụ emerụ n'elu. A na-akpọzi ha site na iji gas nitrogen dị ọcha na igwe nkụ, na-emecha usoro mmepụta ahụ dum.

Mgbe ọtụtụ afọ nke mgbalị gasịrị, enweela ọganihu dị ukwuu na nhazi otu kristal SiC n'ime China. N'ime ụlọ, 100 mm doped semi-insulating 4H-SiC single crystals emeputala nke ọma, na ụdị n-ụdị 4H-SiC na 6H-SiC otu kristal nwere ike imepụta ugbu a na batches. Ụlọ ọrụ dị ka TankeBlue na TYST emepụtalarị otu kristal SiC 150 mm.

N'ihe gbasara teknụzụ nhazi wafer SiC, ụlọ ọrụ ụlọ enyochala nke mbụ ọnọdụ usoro na ụzọ maka slicing crystal, egweri, na polishing. Ha nwere ike ịmepụta ihe nlele nke na-emezu ihe achọrọ maka imepụta ngwaọrụ. Otú ọ dị, e jiri ya tụnyere ụkpụrụ mba ụwa, ogo nhazi elu nke wafers ụlọ ka dị n'azụ nke ukwuu. Enwere ọtụtụ okwu:

A na-echekwa echiche SiC mba ụwa na teknụzụ nhazi nke ọma na ọ naghị adị mfe ịnweta.

Enweghi nyocha nyocha na nkwado maka imeziwanye usoro na njikarịcha.

Ọnụ ego nke mbubata akụrụngwa na akụrụngwa mba ọzọ dị elu.

Nnyocha ụlọ n'ime imepụta akụrụngwa, nhazi nkenke, na ihe ndị ka na-egosi nnukwu oghere ma e jiri ya tụnyere ọkwa mba ụwa.

Ka ọ dị ugbu a, a na-ebubata ọtụtụ ngwá ọrụ dị elu nke a na-eji na China. Ngwá ọrụ ule na usoro na-achọkwa nkwalite ọzọ.

Site na mmepe nke semiconductor ọgbọ nke atọ, dayameta nke mkpụrụ osisi kristal SiC na-abawanye nke ukwuu, yana ihe ndị dị elu chọrọ maka ogo nhazi elu. Nkà na ụzụ nhazi Wafer abụrụla otu n'ime usoro kachasị sie ike na teknụzụ ka otu SiC gachara kristal.

Iji dozie ihe ịma aka ndị dị na nhazi, ọ dị mkpa ịmụba usoro ndị metụtara ịkpụ, ichicha, na polishing, na inyocha usoro na ụzọ dabara adaba maka nrụpụta SiC wafer. N'otu oge ahụ, ọ dị mkpa ịmụta site na nkà na ụzụ nhazi mba ụwa dị elu ma nakwere usoro na akụrụngwa ọgbara ọhụrụ nke ọma iji mepụta ihe ndị dị elu.

Ka nha wafer na-abawanye, ihe isi ike nke uto na nhazi kristal na-ebilikwa. Otú ọ dị, nrụpụta nrụpụta nke ngwaọrụ ndị dị n'okpuru ala na-akawanye mma nke ukwuu, na ọnụ ahịa unit na-ebelata. Ka ọ dị ugbu a, ndị na-eweta SiC wafer zuru ụwa ọnụ na-enye ngwaahịa sitere na sentimita anọ ruo sentimita isii na dayameta. Companieslọ ọrụ ndị isi dị ka Cree na II-VI amalitelarị ime atụmatụ maka mmepe nke ahịrị nrụpụta 8-inch SiC wafer.

Oge nzipu: Mee-23-2025