SiC wafer's abtract

Silicon carbide (SiC) wafersaghọwo ihe a na-ahọrọ maka ngwa eletrik dị elu, nke dị elu, na okpomọkụ dị elu n'ofe ụgbọ ala, ume ọhụrụ na mpaghara ikuku. Pọtụfoliyo anyị na-ekpuchi isi ụdị polytypes na atụmatụ doping-nitrogen-doped 4H (4H-N), ọkara-insulating dị elu (HPSI), nitrogen-doped 3C (3C-N), na p-ụdị 4H / 6H (4H / 6H-P) - enyere na ọkwa atọ dị mma: PRIME (na-emepe emepe nke ọma) Nnwale usoro), na Nchọgharị (ụdị epi oyi akwa na profaịlụ doping maka R&D). Dayameta nke wafer dị 2 ″, 4″, 6″, 8″, na 12″ iji dabara ma ngwaọrụ ihe nketa yana akwa akwa dị elu. Anyị na-ewetakwa boules monocrystalline na kristal mkpụrụ gbakwasara ahụ nke ọma iji kwado uto kristal n'ime ụlọ.

Anyị 4H-N wafers na-egosipụta njupụta nke ụgbọ ala site na 1 × 10¹⁶ ruo 1 × 10¹⁹ cm⁻³ na ihe mgbochi nke 0.01-10 Ω·cm, na-ebuga agagharị elektrọn dị mma na ubi mmebi n'elu 2 MV / cm - dị mma maka Schottky diodes, na JSFET. Mpempe akwụkwọ HPSI gafere 1 × 10¹² Ω·cm resistivity nwere njupụta micropipe dị n'okpuru 0.1 cm⁻², na-ahụ na ntapu nke ntanaka maka RF na ngwaọrụ ngwa ndakwa nri. Cubic 3C-N, dị n'ụdị 2″ na 4″, na-enyere heteroepitaxy aka na silicon ma na-akwado ngwa fotonic na MEMS. P-ụdị 4H/6H-P wafers, doped na aluminom ka 1×10¹⁶–5×10¹⁸ cm⁻³, na-akwado mmeju ngwaọrụ architectures.

SiC wafer, PRIME wafers na-enweta polishing kemịkalụ – igwe na-eme ka <0.2 nm RMS dị nhịahụ elu, nha nha nha n'okpuru 3 µm, na ụta <10 µm. Ihe ntinye DUMMY na-eme ngwa ngwa mgbakọ na ule nkwakọ ngwaahịa, ebe nyocha nyocha na-egosipụta ọkpụrụkpụ epi-layer nke 2-30 µm na bespoke doping. A na-akwado ngwaahịa niile site na X-ray diffraction (mgbatị mgbanaka <30 arcsec) na Raman spectroscopy, na ule eletriki - nha Ụlọ Nzukọ, profaịlụ C-V, na nyocha micropipe-n'ịhụ na JEDEC na SEMI kwadoro.

A na-etolite olulu ruo dayameta 150 mm site na PVT na CVD nwere njupụta dislocation n'okpuru 1 × 10³ cm⁻² yana ọnụ ọgụgụ micropipe dị ala. A na-egbutu kristal mkpụrụ n'ime 0.1º nke axis c-axis iji kwe nkwa uto mmeghari na nnukwu mịka mkpụrụ.

Site na ijikọta ọtụtụ polytypes, doping variants, akara ule dị mma, nha SiC wafer, yana n'ime ụlọ na mmepụta mkpụrụ-kristal, ikpo okwu SiC anyị na-eme ka agbụ ọkọnọ ma na-eme ka mmepe ngwaọrụ maka ụgbọ ala eletrik, grids smart, na ngwa gburugburu ebe obibi siri ike.

SiC wafer's abtract

Silicon carbide (SiC) wafersaghọọla mkpụrụ nke SiC nke nhọrọ maka ike dị elu, nke dị elu na ngwa eletrọnịkị dị elu n'ofe ụgbọ ala, ike mmeghari ohuru, na ngalaba ikuku. Pọtụfoliyo anyị na-ekpuchi isi polytypes na atụmatụ doping-nitrogen-doped 4H (4H-N), ọkara-insulating dị elu (HPSI), nitrogen-doped 3C (3C-N), na p-ụdị 4H / 6H (4H / 6H-P) - nke enyere na akara ule atọ: SiC waferPRIME (nke a na-egbu maramara nke ọma, ihe ndị nwere ọkwa ngwaọrụ), DUMMY (rapaara ma ọ bụ emebeghi ya maka ule usoro), na Nchọgharị (nchịkọta epi omenala na profaịlụ doping maka R&D). Dayameta SiC Wafer dị 2 ″, 4″, 6″, 8″, na 12″ iji dabara ma ngwaọrụ ihe nketa yana akwa akwa dị elu. Anyị na-ewetakwa boules monocrystalline na kristal mkpụrụ gbakwasara ahụ nke ọma iji kwado uto kristal n'ime ụlọ.

Anyị 4H-N SiC wafers na-egosipụta njupụta nke ụgbọ ala sitere na 1 × 10¹⁶ ruo 1 × 10¹⁹ cm⁻³ na ihe mgbochi nke 0.01-10 Ω·cm, na-ebuga ngagharị elektrọn dị mma na mpaghara mmebi n'elu 2 MV/cm — dị mma maka Schottky diodes, na MOSFET. Mpempe akwụkwọ HPSI gafere 1 × 10¹² Ω·cm resistivity nwere njupụta micropipe dị n'okpuru 0.1 cm⁻², na-ahụ na ntapu nke ntanaka maka RF na ngwaọrụ ngwa ndakwa nri. Cubic 3C-N, dị n'ụdị 2″ na 4″, na-enyere heteroepitaxy aka na silicon ma na-akwado ngwa fotonic na MEMS. Ụdị SiC wafer P-ụdị 4H/6H-P, nke ejiri aluminom mee ka ọ bụrụ 1 × 10¹⁶-5 × 10¹⁸ cm⁻³, na-eme ka nhazi ngwaọrụ arụkọ ọrụ.

SiC wafer PRIME wafers na-enweta polishing kemịkalụ – igwe ruo <0.2 nm RMS nhụsianya elu, nha nha nha n'okpuru 3 µm, na ụta <10 µm. Ihe ntinye DUMMY na-eme ngwa ngwa mgbakọ na ule nkwakọ ngwaahịa, ebe nyocha nyocha na-egosipụta ọkpụrụkpụ epi-layer nke 2-30 µm na bespoke doping. A na-akwado ngwaahịa niile site na X-ray diffraction (mgbatị mgbanaka <30 arcsec) na Raman spectroscopy, na ule eletriki - nha Ụlọ Nzukọ, profaịlụ C-V, na nyocha micropipe-n'ịhụ na JEDEC na SEMI kwadoro.

A na-etolite olulu ruo dayameta 150 mm site na PVT na CVD nwere njupụta dislocation n'okpuru 1 × 10³ cm⁻² yana ọnụ ọgụgụ micropipe dị ala. A na-egbutu kristal mkpụrụ n'ime 0.1º nke axis c-axis iji kwe nkwa uto mmeghari na nnukwu mịka mkpụrụ.

Site na ijikọta ọtụtụ polytypes, doping variants, akara ule dị mma, nha SiC wafer, yana n'ime ụlọ na mmepụta mkpụrụ-kristal, ikpo okwu SiC anyị na-eme ka agbụ ọkọnọ ma na-eme ka mmepe ngwaọrụ maka ụgbọ ala eletrik, grids smart, na ngwa gburugburu ebe obibi siri ike.

6inch 4H-N ụdị akwụkwọ data SiC wafer

| 6 inch SiC wafers mpempe akwụkwọ | ||||

| Oke | Nkeji ala | Z ọkwa | P ọkwa | D ọkwa |

| Dayameta | 149.5-150.0 mm | 149.5-150.0 mm | 149.5-150.0 mm | |

| Ọkpụrụkpụ | 4H-N | 350 µm ± 15 µm | 350 µm ± 25 µm | 350 µm ± 25 µm |

| Ọkpụrụkpụ | 4H-SI | 500 µm ± 15 µm | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Usoro Wafer | Gbanyụọ axis: 4.0° chere ihu <11-20> ±0.5° (4H-N); Na axis: <0001> ± 0.5° (4H-SI) | Gbanyụọ axis: 4.0° chere ihu <11-20> ±0.5° (4H-N); Na axis: <0001> ± 0.5° (4H-SI) | Gbanyụọ axis: 4.0° chere ihu <11-20> ±0.5° (4H-N); Na axis: <0001> ± 0.5° (4H-SI) | |

| Njupụta Micropipe | 4H-N | ≤ 0.2 cm⁻² | ≤2 cm⁻² | ≤ 15 cm⁻² |

| Njupụta Micropipe | 4H-SI | ≤ 1 cm⁻² | ≤5 cm ² | ≤ 15 cm⁻² |

| Nguzogide | 4H-N | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | 0.015–0.028 Ω·cm |

| Nguzogide | 4H-SI | ≥ 1×10¹⁰ Ω·cm | ≥ 1 × 10⁵ Ω·cm | |

| Nhazi Flat nke izizi | [10-10] ± 5.0° | [10-10] ± 5.0° | [10-10] ± 5.0° | |

| Ogologo Flat nke izizi | 4H-N | 47.5 mm ± 2.0 mm | ||

| Ogologo Flat nke izizi | 4H-SI | Ọkwa | ||

| Mwepu ihu | 3 mm | |||

| Warp/LTV/TTV/Ụta | ≤2.5 µm / ≤6 µm / ≤25 µm / ≤35 µm | ≤5 µm / ≤15 µm / ≤40 µm / ≤60 µm | ||

| Isi ike | Polish | Ra ≤ 1 nm | ||

| Isi ike | CMP | Ra ≤ 0.2 nm | Ra ≤ 0.5 nm | |

| Ọnụ mgbawa | Ọ dịghị | Ogologo ngụkọta ≤ 20 mm, otu ≤ 2 mm | ||

| Efere Hex | Mpaghara mkpokọta ≤ 0.05% | Mpaghara mkpokọta ≤ 0.1% | Mpaghara mkpokọta ≤ 1% | |

| Mpaghara Polytype | Ọ dịghị | Mpaghara mkpokọta ≤ 3% | Mpaghara mkpokọta ≤ 3% | |

| Mgbakwunye carbon | Mpaghara mkpokọta ≤ 0.05% | Mpaghara mkpokọta ≤ 3% | ||

| Ọkpụkpụ n'elu | Ọ dịghị | Ogologo ngụkọta ≤ 1 × dayameta wafer | ||

| ibe ibe | Ọnweghị nke enyere ikike ≥ 0.2 mm obosara & omimi | Ruo 7 ibe, ≤ 1 mm nke ọ bụla | ||

| TSD (Mgbasa nke eriri eriri) | ≤500 cm⁻² | N/A | ||

| BPD (Ntugharị ụgbọ elu) | ≤ 1000 cm⁻² | N/A | ||

| Mmetọ Elu | Ọ dịghị | |||

| Nkwakọ ngwaahịa | Multi-wafer cassette ma ọ bụ otu akpa wafer | Multi-wafer cassette ma ọ bụ otu akpa wafer | Multi-wafer cassette ma ọ bụ otu akpa wafer | |

4inch 4H-N ụdị akwụkwọ data SiC wafer

| Mpempe akwụkwọ data SiC wafer 4inch | |||

| Oke | Mmepụta MPD efu | Ọkọlọtọ Mmepụta Ọkachamara (P Ọkwa) | Ngụsị akwụkwọ (D grade) |

| Dayameta | 99.5 mm-100.0 mm | ||

| Ọkpụrụkpụ (4H-N) | 350 µm± 15 µm | 350 µm±25 µm | |

| Ọkpụrụkpụ (4H-Si) | 500 µm± 15 µm | 500 µm±25 µm | |

| Usoro Wafer | Gbanyụọ axis: 4.0° chere ihu <1120> ± 0.5° maka 4H-N; Na axis: <0001> ± 0.5° maka 4H-Si | ||

| Njupụta Micropipe (4H-N) | ≤0.2 cm⁻² | ≤2 cm ² | ≤15 cm ² |

| Njupụta Micropipe (4H-Si) | ≤1 cm ² | ≤5 cm ² | ≤15 cm ² |

| Nguzogide (4H-N) | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | |

| Nguzogide (4H-Si) | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |

| Nhazi Flat nke izizi | [10-10] ±5.0° | ||

| Ogologo Flat nke izizi | 32.5 mm ± 2.0 mm | ||

| Ogologo Flat nke abụọ | 18.0 mm ± 2.0 mm | ||

| Nhazi Flat nke abụọ | Silicon na-eche ihu: 90° CW site na isi larịị ± 5.0° | ||

| Mwepu ihu | 3 mm | ||

| LTV/TTV/Bow Warp | ≤2.5 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Isi ike | Polish Ra ≤1 nm; CMP Ra ≤0.2 nm | Ra ≤0.5 nm | |

| Edge cracks Site na nnukwu ọkụ ọkụ | Ọ dịghị | Ọ dịghị | Ogologo mkpokọta ≤10 mm; otu ogologo ≤2 mm |

| Efere Hex Site na Ìhè Dị Elu | Mpaghara mkpokọta ≤0.05% | Mpaghara mkpokọta ≤0.05% | Mpaghara mkpokọta ≤0.1% |

| Mpaghara Polytype Site n'ìhè dị elu | Ọ dịghị | Mpaghara mkpokọta ≤3% | |

| Ntinye Carbon Anya Anya | Mpaghara mkpokọta ≤0.05% | Mpaghara mkpokọta ≤3% | |

| Silicon dị n'elu Scratches Site na nnukwu ọkụ ọkụ | Ọ dịghị | Ogologo ngụkọta ≤1 dayameta wafer | |

| Chips Edge Site na Ìhè Dị Elu | Ọnweghị nke enyere ikike ≥0.2 mm obosara na omimi | 5 kwere, ≤1 mm nke ọ bụla | |

| Mmetọ Silicon dị n'elu site na ọkụ dị elu | Ọ dịghị | ||

| Mkpọsa nke eriri eriri | ≤500 cm ² | N/A | |

| Nkwakọ ngwaahịa | Multi-wafer cassette ma ọ bụ otu akpa wafer | Multi-wafer cassette ma ọ bụ otu akpa wafer | Multi-wafer cassette ma ọ bụ otu akpa wafer |

4inch HPSI ụdị SiC data mpempe akwụkwọ

| 4inch HPSI ụdị SiC data mpempe akwụkwọ | |||

| Oke | Ọkwa mmepụta MPD efu (ọkwa Z) | Ọkọlọtọ Mmepụta Ọkachamara (P Ọkwa) | Ngụsị akwụkwọ (D grade) |

| Dayameta | 99.5-100.0 mm | ||

| Ọkpụrụkpụ (4H-Si) | 500 µm ± 20 µm | 500 µm ± 25 µm | |

| Usoro Wafer | Gbanyụọ axis: 4.0 ° gaa na <11-20> ± 0.5° maka 4H-N; Na axis: <0001> ± 0.5° maka 4H-Si | ||

| Njupụta Micropipe (4H-Si) | ≤1 cm ² | ≤5 cm ² | ≤15 cm ² |

| Nguzogide (4H-Si) | ≥1E9 Ω·cm | ≥1E5 Ω·cm | |

| Nhazi Flat nke izizi | (10-10) ±5.0° | ||

| Ogologo Flat nke izizi | 32.5 mm ± 2.0 mm | ||

| Ogologo Flat nke abụọ | 18.0 mm ± 2.0 mm | ||

| Nhazi Flat nke abụọ | Silicon na-eche ihu: 90° CW site na isi larịị ± 5.0° | ||

| Mwepu ihu | 3 mm | ||

| LTV/TTV/Bow Warp | ≤3 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Ihu ihu (C ihu) | Polish | Ra ≤1 nm | |

| Ihe isi ike (Si ihu) | CMP | Ra ≤0.2 nm | Ra ≤0.5 nm |

| Edge cracks Site na nnukwu ọkụ ọkụ | Ọ dịghị | Ogologo mkpokọta ≤10 mm; otu ogologo ≤2 mm | |

| Efere Hex Site na Ìhè Dị Elu | Mpaghara mkpokọta ≤0.05% | Mpaghara mkpokọta ≤0.05% | Mpaghara mkpokọta ≤0.1% |

| Mpaghara Polytype Site n'ìhè dị elu | Ọ dịghị | Mpaghara mkpokọta ≤3% | |

| Ntinye Carbon Anya Anya | Mpaghara mkpokọta ≤0.05% | Mpaghara mkpokọta ≤3% | |

| Silicon dị n'elu Scratches Site na nnukwu ọkụ ọkụ | Ọ dịghị | Ogologo ngụkọta ≤1 dayameta wafer | |

| Chips Edge Site na Ìhè Dị Elu | Ọnweghị nke enyere ikike ≥0.2 mm obosara na omimi | 5 kwere, ≤1 mm nke ọ bụla | |

| Mmetọ Silicon dị n'elu site na ọkụ dị elu | Ọ dịghị | Ọ dịghị | |

| Mgbasa nke eriri eriri | ≤500 cm ² | N/A | |

| Nkwakọ ngwaahịa | Multi-wafer cassette ma ọ bụ otu akpa wafer | ||

Ngwa SiC wafer

-

Modul ike SiC Wafer maka ndị ntụgharị EV

MOSFET dabere na SiC wafer na diodes wuru na mkpụrụ osisi SiC wafer dị elu na-ebuga mfu ngbanwe dị ala. Site na iji teknụzụ wafer SiC, modul ike ndị a na-arụ ọrụ na voltaji na okpomọkụ dị elu, na-eme ka ndị ntụgharị traction na-arụ ọrụ nke ọma karị. Ijikọ SiC wafer na-anwụ n'ime ọkwa ike na-ebelata ihe jụrụ oyi na akara ukwu, na-egosipụta ikike ọhụrụ nke SiC wafer. -

Ngwa RF & 5G dị elu na SiC Wafer

RF amplifiers na switches arụpụtara na ọkara mkpuchi mkpuchi SiC wafer nyiwe na-egosipụta arụmọrụ ọkụ dị elu yana voltaji ndakpọ. Ngwa SiC wafer na-ebelata mfu dielectric na ugboro ugboro GHz, ebe ike ihe SiC wafer na-enye ohere maka ịrụ ọrụ kwụsiri ike n'okpuru ike dị elu, ọnọdụ okpomọkụ dị elu-na-eme SiC wafer ka ọ bụrụ mkpụrụ nke nhọrọ maka ọdụ ụgbọ ala 5G na-esote na sistemụ radar. -

Ngwa ngwa Optoelectronic & LED sitere na SiC Wafer

Igwe ọkụ na-acha anụnụ anụnụ na UV toro na mkpụrụ osisi SiC wafer na-erite uru site na ndakọrịta lattice mara mma na mkpofu ọkụ. Iji C-face SiC wafer na-egbu maramara na-eme ka akwa epitaxial edo edo edo, ebe ike siri ike nke SiC wafer na-eme ka ọ dị nro na nkwakọ ngwaahịa a pụrụ ịdabere na ya. Nke a na-eme SiC wafer na-aga-na ikpo okwu maka elu-ike, ogologo ndụ LED ngwa.

Ajụjụ&A nke SiC wafer

1. Ajụjụ: Kedu ka esi arụpụta SiC wafers?

A:

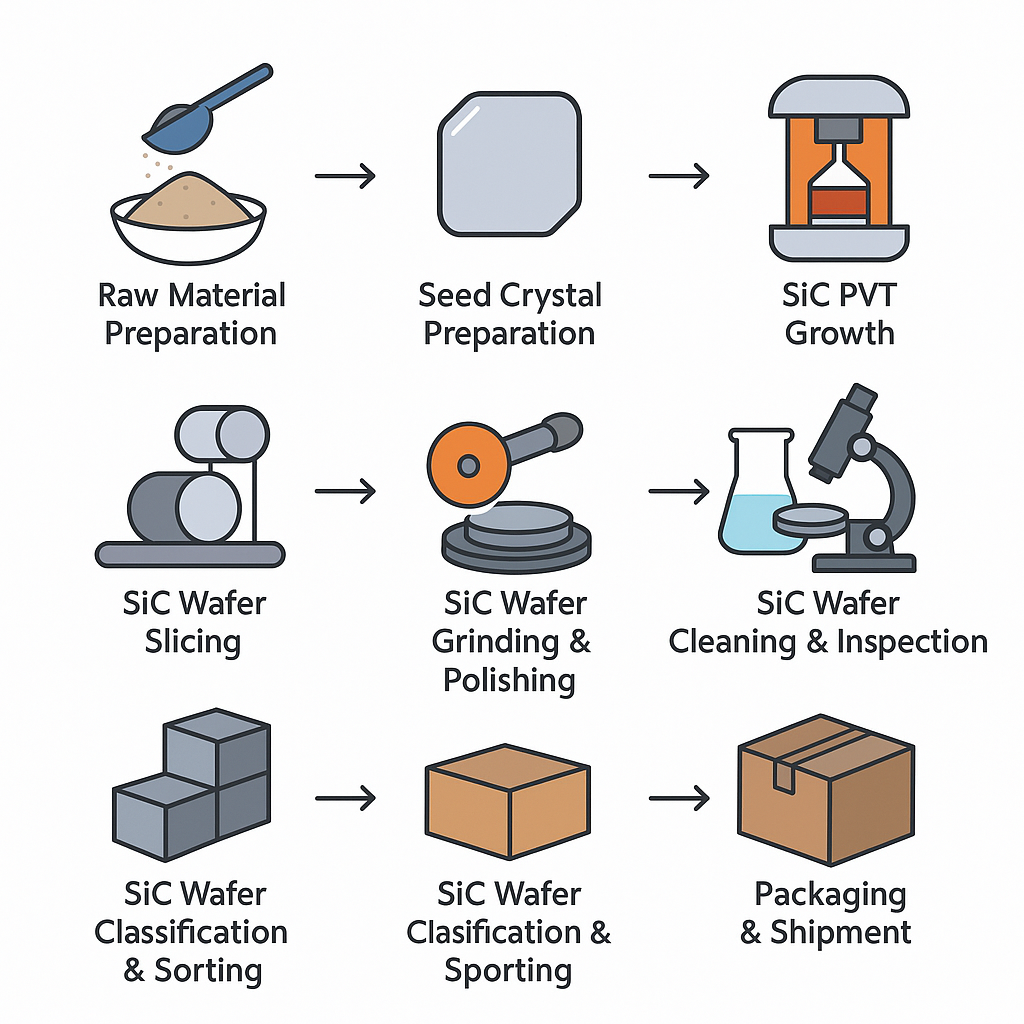

SiC wafer arụpụtaraNzọụkwụ zuru ezu

-

SiC wafersNkwadebe ihe eji eme ihe

- Jiri ≥5N-ọkwa SiC ntụ ntụ (adịghị ọcha ≤1 ppm).

- Sie na tupu akpọọ nkụ iji wepu carbon ma ọ bụ ogige nitrogen fọdụrụnụ.

-

SiCNkwadebe mkpụrụ kristal

-

Were otu kristal 4H-SiC, iberi n'akụkụ 〈0001〉 ruo ~10 × 10 mm².

-

Ntucha nkenke ka Ra ≤0.1 nm wee kaa akara ntuziaka kristal.

-

-

SiCUto PVT ( Transportgbọ njem anụ ahụ)

-

Ibu graphite crucible: ala na SiC ntụ ntụ, n'elu ya na kristal mkpụrụ.

-

Wepụ na 10⁻³–10⁻ Torr ma ọ bụ jiri helium dị ọcha jupụta na 1 atm.

-

Mpaghara ebe a na-ekpo ọkụ ruo 2100-2300 ℃, debe mpaghara mkpụrụ osisi 100-150 ℃ ngwa nju oyi.

-

Na-achịkwa ọnụego uto na 1-5 mm / h iji dozie ịdịmma na ntinye aka.

-

-

SiCIngot Annealing

-

Wepu SiC ingot ka tolitere na 1600–1800 ℃ maka awa 4–8.

-

Ebumnuche: belata nrụgide okpomọkụ ma belata njupụta dislocation.

-

-

SiCIberibe wafer

-

Jiri eriri diamond kụrie ingot n'ime wafer gbara ọkpụrụkpụ 0.5-1 mm.

-

Wedata mmaji na mpụta iji zere obere mgbawa.

-

-

SiCWaferNa-egweri & polishing

-

Egweri siri ikeiji wepụ mmebi ịwa ahụ (ihe siri ike ~ 10-30 µm).

-

Egweri nke ọmaiji nweta flatness ≤5 µm.

-

Chemical-Mechanical Polishing (CMP)iru enyo enyo (Ra ≤0.2 nm).

-

-

SiCWaferNchacha & Nyocha

-

Ultrasonic nhichana ngwọta Piranha (H₂SO₄: H₂O₂), mmiri DI, wee IPA.

-

XRD/Raman spectroscopyiji kwado polytype (4H, 6H, 3C).

-

Interferometryiji tụọ flatness (<5 µm) na warp (<20 µm).

-

Nyocha anọiji nwalee resistivity (dịka HPSI ≥10⁹ Ω·cm).

-

Nyocha adịghị mman'okpuru polarized ìhè mikroskopu na ọkọ tester.

-

-

SiCWaferNhazi & Nhazi

-

Hazie wafer site na polytype na ụdị eletrik:

-

4H-SiC N-ụdị (4H-N): ntinye uche nke ebu 10¹⁶–10¹⁸ cm⁻³

-

4H-SiC High Purity Semi-Insulating (4H-HPSI): resistivity ≥10⁹ Ω · cm

-

6H-SiC N-ụdị (6H-N)

-

Ndị ọzọ: 3C-SiC, P-ụdị, wdg.

-

-

-

SiCWaferNkwakọ ngwaahịa & Mbupu

2. Ajụjụ: Gịnị bụ isi uru nke SiC wafers n'elu silicon wafers?

A: E jiri ya tụnyere silicon wafers, SiC wafers na-enyere:

-

Ịrụ ọrụ voltaji dị elu(> 1,200 V) nwere obere nguzogide.

-

Nkwụsi ike okpomọkụ dị elu(> 300 Celsius) na njikwa okpomọkụ ka mma.

-

Ọsọ ngbanwe ọsọ ọsọna mfu mgbanwe mgbanwe dị ala, na-ebelata nhazi ọkwa sistemụ na nha na ndị ntụgharị ike.

4. Ajụjụ: Kedu ntụpọ nkịtị na-emetụta mkpụrụ na arụmọrụ SiC wafer?

A: Nrụrụ ndị bụ isi na wafers SiC gụnyere micropipes, mgbakasị ụgbọ elu basal (BPDs), na ncha elu. Micropipes nwere ike ịkpata ọdịda ngwaọrụ ọdachi; BPD na-abawanye na-eguzogide ka oge na-aga; na nchapu elu na-eduga na mgbaji wafer ma ọ bụ uto epitaxial na-adịghị mma. Ya mere, nleba anya siri ike na mbelata ntụpọ dị mkpa iji bulie mkpụrụ wafer SiC.

Oge nzipu: Jun-30-2025