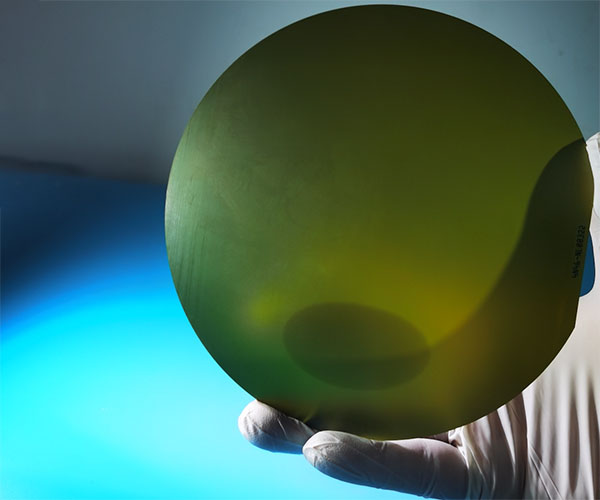

Ka ọ dị ugbu a, ụlọ ọrụ anyị nwere ike ịga n'ihu na-enye obere ụdị 8inchN ụdị SiC wafers, ọ bụrụ na ị nwere mkpa nlele, biko nweere onwe gị ịkpọtụrụ m. Anyị nwere ụfọdụ wafer dị njikere ibupu.

N'ihe gbasara ihe semiconductor, ụlọ ọrụ ahụ emeela nnukwu ọganihu na nyocha na mmepe nke nnukwu kristal SiC. Site na iji ya mkpụrụ kristal mgbe multiple agba nke dayameta mgbasawanye, ụlọ ọrụ emewo nke ọma toro 8-inch N-ụdị SiC kristal, nke na-edozi nsogbu siri ike dị ka uneven okpomọkụ ubi, kristal cracking na gas na-adọ akụrụngwa nkesa na uto usoro nke 8-inch SIC kristal, na accelerates uto nke nnukwu size SIC kristal na ndị kwụụrụ onwe na njikwa teknụzụ. Mee ka nnukwu asọmpi isi ụlọ ọrụ na ụlọ ọrụ mkpụrụ kristal SiC dị. N'otu oge ahụ, ụlọ ọrụ na-arụsi ọrụ ike na-akwalite ìgwè nke technology na usoro nke nnukwu size silicon carbide mkpụrụ nkwadebe nnwale akara, na-ewusi teknuzu mgbanwe na ulo oru mmekota na upstream na downstream ubi, na collaborates na ndị ahịa ka mgbe niile iterate ngwaahịa arụmọrụ, na nkwonkwo na-akwalite ijeụkwụ nke ulo oru ngwa nke silicon carbide ihe.

| 8inch N-ụdị SiC DSP Species | |||||

| Nọmba | Ihe | Nkeji | Mmepụta | Nnyocha | Dummy |

| 1. Parameters | |||||

| 1.1 | polytype | -- | 4H | 4H | 4H |

| 1.2 | nghazi elu | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Igwe ọkụ eletrik | |||||

| 2.1 | dopant | -- | n-ụdị Nitrogen | n-ụdị Nitrogen | n-ụdị Nitrogen |

| 2.2 | resistivity | ohm · cm | 0.015-0.025 | 0.01-0.03 | NA |

| 3. Mechanical paramita | |||||

| 3.1 | dayameta | mm | 200±0.2 | 200±0.2 | 200±0.2 |

| 3.2 | ọkpụrụkpụ | μm | 500± 25 | 500± 25 | 500± 25 |

| 3.3 | Ntughari notch | ° | [1-100]±5 | [1-100]±5 | [1-100]±5 |

| 3.4 | Omimi Ọkwa | mm | 1-1.5 | 1-1.5 | 1-1.5 |

| 3.5 | LTV | μm | ≤5 (10mm*10mm) | ≤5 (10mm*10mm) | ≤10 (10mm*10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Ụta | μm | -25-25 | -45-45 | -65-65 |

| 3.8 | Warp | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | ≤0.2 | ≤0.2 | ≤0.2 |

| 4. Ihe owuwu | |||||

| 4.1 | njupụta micropipe | ihe / cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | ígwè ọdịnaya | atom / cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | ihe / cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | ihe / cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | ihe / cm2 | ≤7000 | ≤10000 | NA |

| 5. Mma mma | |||||

| 5.1 | n'ihu | -- | Si | Si | Si |

| 5.2 | elu imecha | -- | Si-ihu CMP | Si-ihu CMP | Si-ihu CMP |

| 5.3 | urughuru | ea/wafer | ≤100 (nha≥0.3μm) | NA | NA |

| 5.4 | ọkọ | ea/wafer | ≤5, ngụkọta ogologo≤200mm | NA | NA |

| 5.5 | Ọnụ ibe / indents / mgbawa / ntụpọ / mmetọ | -- | Ọ dịghị | Ọ dịghị | NA |

| 5.6 | Mpaghara polytype | -- | Ọ dịghị | Mpaghara ≤10% | Mpaghara ≤30% |

| 5.7 | akara n'ihu | -- | Ọ dịghị | Ọ dịghị | Ọ dịghị |

| 6. Azụ àgwà | |||||

| 6.1 | azụ imecha | -- | C-ihu MP | C-ihu MP | C-ihu MP |

| 6.2 | ọkọ | mm | NA | NA | NA |

| 6.3 | Akụkụ ntụpọ azụ ibe / indents | -- | Ọ dịghị | Ọ dịghị | NA |

| 6.4 | Azụ isi ike | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Akara azụ | -- | Ọkwa | Ọkwa | Ọkwa |

| 7. Nri | |||||

| 7.1 | onu | -- | Chamfer | Chamfer | Chamfer |

| 8. ngwugwu | |||||

| 8.1 | nkwakọ ngwaahịa | -- | Epi-njikere na agụụ nkwakọ ngwaahịa | Epi-njikere na agụụ nkwakọ ngwaahịa | Epi-njikere na agụụ nkwakọ ngwaahịa |

| 8.2 | nkwakọ ngwaahịa | -- | Multi-wafer ngwugwu cassette | Multi-wafer ngwugwu cassette | Multi-wafer ngwugwu cassette |

Oge nzipu: Eprel-18-2023