Ajụjụ: Gịnị bụ isi teknụzụ eji na SiC wafer slicing na nhazi?

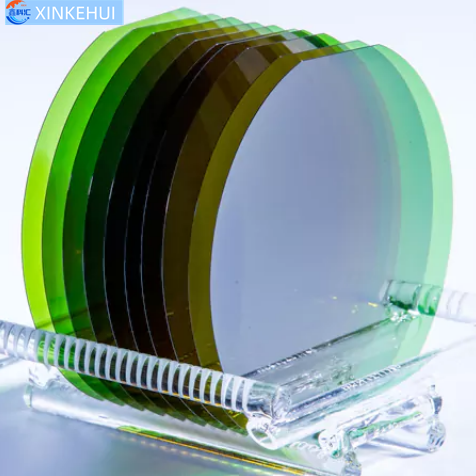

A:Silicon carbide (SiC) nwere ihe isi ike nke abụọ na naanị diamond ma a na-ahụta ya dị ka ihe siri ike na nke na-emebi emebi. Usoro ịkpụchasị ahụ, nke gụnyere igbutu kristal toro eto ka ọ bụrụ obere wafer, na-ewe oge ma na-adịkarị mfe ịkụcha. Dị ka nzọụkwụ mbụ naSiCnhazi otu kristal, ịdị mma nke slicing na-emetụta nke ọma n'ichichi, polishing, na thinning. Iberibe na-ebutekarị mgbawa elu na nke dị n'okpuru ala, na-abawanye ọnụego nkwụsịtụ wafer na ọnụ ahịa mmepụta. Ya mere, ịchịkwa mmebi mgbawa elu n'oge ịkpụ dị mkpa maka ịkwalite nrụpụta ngwaọrụ SiC.

Ụzọ slicing SiC a na-akọ ugbu a gụnyere slicing ofu-abrasive, free-abrasive slicing, laser ịkpụ, mbufe oyi akwa (nkewa oyi), na mwepu ọkụ eletrik. N'ime ndị a, ịweghachi ọtụtụ waya na-eji abrasives diamond edoziri bụ usoro a na-ejikarị eme ihe maka nhazi otu kristal SiC. Agbanyeghị, ka nha ingot ruru sentimita asatọ na n'elu, ịwa waya ọdịnala na-adịchaghị mma n'ihi nnukwu akụrụngwa chọrọ, ọnụ ahịa na arụmọrụ dị ala. Enwere mkpa ngwa ngwa maka teknụzụ slicing dị ọnụ ala, dị ala, na-arụ ọrụ nke ọma.

Q: Gịnị bụ uru nke laser slicing n'elu omenala multi-waya ọnwụ?

A: Ịwa waya ọdịnala na-egbutu yaSiC nwetaratinyere a kpọmkwem ntụziaka n'ime mpekere ọtụtụ narị microns oké. A na-akụzi mpekere ndị ahụ site na iji slurries diamond iji wepụ akara nhụsịrị na mmebi dị n'okpuru ala, na-esote chemical mechanical polishing (CMP) iji nweta atụmatụ zuru ụwa ọnụ, ma mesịa kpochaa ya iji nweta wafers SiC.

Otú ọ dị, n'ihi isi ike siri ike na nke siri ike nke SiC, usoro ndị a nwere ike ime ka ọ dị mfe ịlụ ọgụ, mgbawa, ọnụ ọgụgụ na-agbaji agbaji, ọnụ ahịa mmepụta dị elu, ma mee ka elu elu dị elu na mmetọ (uzuzu, mmiri mkpofu, wdg). Ọzọkwa, ịwa waya na-adị ngwa ngwa ma nwee obere mkpụrụ. Atụmatụ na-egosi na omenala multi-waya slicing na-enweta nanị ihe dị ka 50% ihe onwunwe itinye n'ọrụ, na ruo 75% nke ihe onwunwe na-efunahụ mgbe polishing na egweri. Ihe omuma mbuputa nke mba ozo gosiputara na o nwere ike were ihe dika ubochi 273 nke mmeputa awa 24 na-aga n'ihu iji weputa wafer 10,000 - na-ewe oge.

N'ime ụlọ, ọtụtụ ụlọ ọrụ uto kristal SiC na-elekwasị anya n'ịbawanye ikike ọkụ. Otú ọ dị, kama ịgbasa mmepụta, ọ dị mkpa ka ị tụlee otú e si ebelata mfu-karịsịa mgbe mkpụrụ osisi kristal adịchaghị mma.

Ngwá ọrụ slicing laser nwere ike ibelata mfu ihe ma melite mkpụrụ. Dị ka ihe atụ, na-eji otu 20 mmSiC nwetara: Wire sawing nwere ike inye gburugburu 30 wafers nke 350 μm ọkpụrụkpụ. Laser slicing nwere ike inye ihe karịrị 50 wafers.If wafer ọkpụrụkpụ na-ebelata ka 200 μm, ihe karịrị 80 wafers nwere ike na-emepụta si otu ingot. ụbọchị na usoro omenala, na-achọ ngwá ọrụ dị elu ma na-akpata ụgwọ dị elu na obere arụmọrụ. N'okpuru ọnọdụ ndị a, uru slicing laser na-apụta ìhè, na-eme ka ọ bụrụ teknụzụ na-eme n'ọdịnihu maka wafers 8-inch.

Site na ịcha laser, oge ịkpụ n'ime wafer 8-inch nwere ike ịdị n'okpuru nkeji 20, yana ihe mfu kwa wafer n'okpuru 60 μm.

Na nchịkọta, ma e jiri ya tụnyere ịcha waya multi-waya, laser slicing na-enye ọsọ ọsọ dị elu, mkpụrụ ka mma, nkwụsị ihe onwunwe dị ala, na nhazi dị ọcha.

Ajụjụ: Gịnị bụ isi ọrụ aka aka mgba na SiC laser slicing?

A: The Laser slicing usoro na-agụnye isi nzọụkwụ abụọ: laser mgbanwe na wafer nkewa.

Isi ihe ngbanwe nke laser bụ nhazi beam na njikarịcha oke. Oke dị ka ike laser, dayameta ntụpọ, na ọsọ nyocha niile na-emetụta ịdịmma nke mkpochapụ ihe yana ịga nke ọma nkewapụ wafer na-esote. Geometry nke mpaghara a gbanwere na-ekpebi ịdị njọ nke elu na ihe isi ike nke nkewa. Ịdị elu elu dị elu na-eme ka egweri emechaa na-abawanye ụba ihe onwunwe.

Mgbe emezigharịrị, a na-enweta nkewa wafer site na ike ịkwa akwa, dị ka mgbaji oyi ma ọ bụ nrụgide ọrụ. Ụfọdụ usoro ụlọ na-eji ultrasonic transducers kpalite vibrations maka nkewa, ma nke a nwere ike ime ka chipping na nsọtụ ntụpọ, wedata ikpeazụ mkpụrụ.

Ọ bụ ezie na usoro abụọ a abụghị ihe siri ike n'ebumnobi, enweghị nkwekọrịta na ịdịmma kristal-n'ihi usoro uto dị iche iche, ọkwa doping, na nkesa nrụgide dị n'ime - na-emetụta nke ọma nhịahụ siri ike, mkpụrụ, na mfu ihe. Naanị ịchọpụta ebe nsogbu na imezi mpaghara nyocha laser nwere ike ọ gaghị eme ka nsonaazụ ya dịkwuo mma.

Isi ihe na-eme ka nkuchi zuru ebe niile bụ n'ịzụlite ụzọ na akụrụngwa ọhụrụ nke nwere ike ime mgbanwe na ụdị kristal dị iche iche sitere na ndị na-emepụta ihe dị iche iche, na-ebuli usoro usoro, na iwulite sistemu slicing laser na ngwa zuru ụwa ọnụ.

Ajụjụ: Enwere ike itinye teknụzụ slicing laser na ihe ndị ọzọ semiconductor ma e wezụga SiC?

A: A na-etinye teknụzụ ịkpụ laser n'akụkọ ihe mere eme n'ọtụtụ ihe. N'ime semiconductor, a na-eji ya na mbụ maka ịkụ wafer ma gbasaala ruo n'ibe nnukwu kristal otu.

E wezụga SiC, a pụkwara iji slicing laser mee ihe ndị ọzọ siri ike ma ọ bụ ihe na-adịghị ike dị ka diamond, gallium nitride (GaN), na gallium oxide (Ga₂O₃). Ọmụmụ ihe mbụ na ihe ndị a egosila na ọ ga-ekwe omume na uru dị na slicing laser maka ngwa semiconductor.

Ajụjụ: Enwere ngwaahịa akụrụngwa slicing laser tozuru oke ugbu a? Kedu ọkwa nyocha gị na ya?

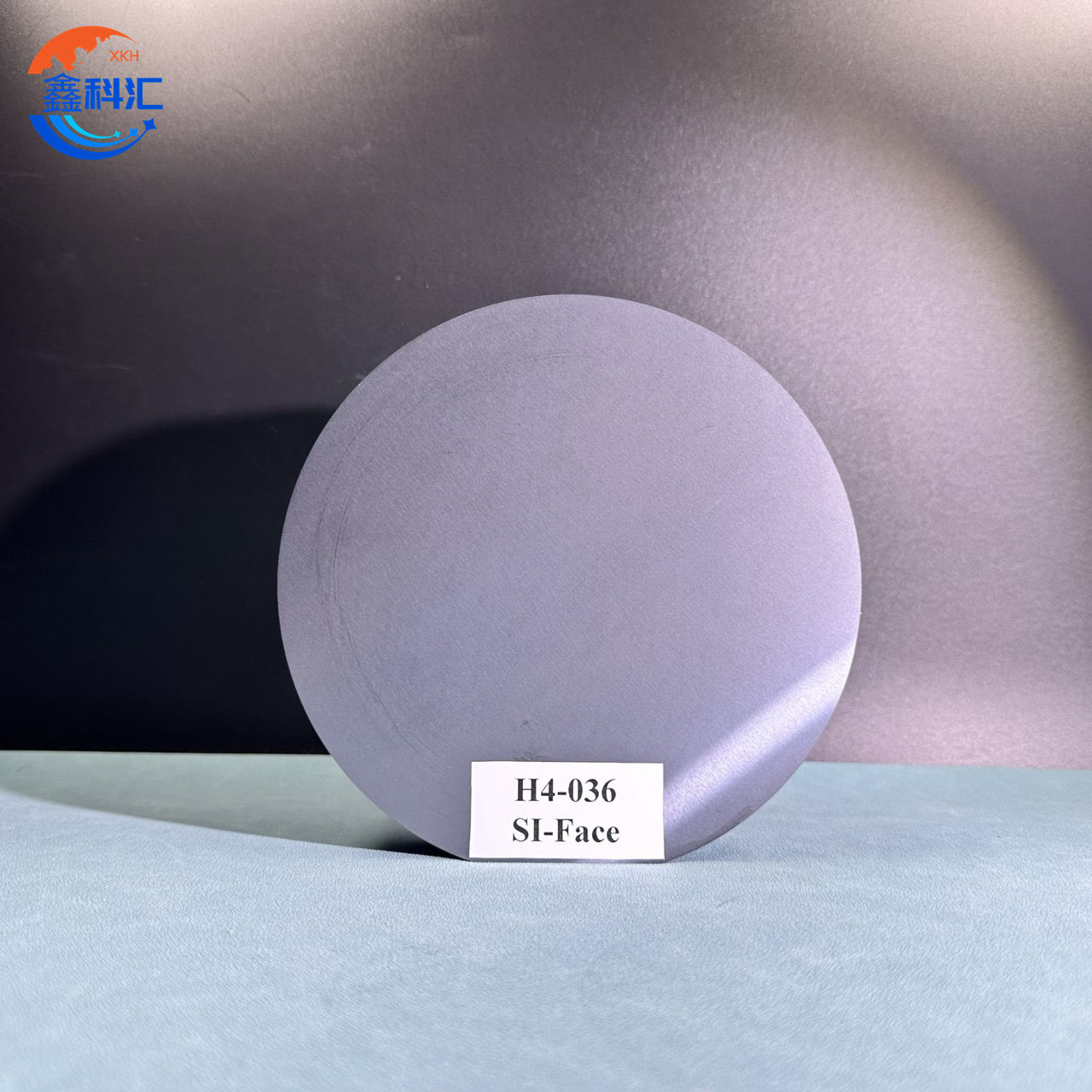

A: A na-ahụta akụrụngwa SiC laser slicing nnukwu dayameta bụ isi akụrụngwa maka ọdịnihu nke 8-inch SiC wafer mmepụta. Ka ọ dị ugbu a, ọ bụ naanị Japan nwere ike ịnye usoro ndị dị otú ahụ, ma ha dị oke ọnụ ma na-adabere na mgbochi mbupụ.

A na-eche na ọchichọ ụlọ maka sistemu slicing / thinning laser ga-adị ihe dị ka nkeji 1,000, dabere na atụmatụ mmepụta SiC na ikike ịkwọ waya dị adị. Ndị isi ụlọ ọrụ etinyela nnukwu ego na mmepe, mana ọ nweghị akụrụngwa ụlọ tozuru oke, nke a na-ere ahịa erutela n'ọrụ ụlọ ọrụ.

Ndị otu nyocha na-azụlite teknụzụ na-ebuli elu laser nwere ebe ọ bụ na 2001 ma gbasaa ugbu a na slicing SiC laser buru ibu na ịhịa aka n'ahụ. Ha emepụtala usoro ihe atụ na usoro slicing nke nwere ike: Ịcha na ịcha 4-6 inch semi-insulating SiC wafersSlicing 6-8 inch conductive SiC ingots Ngosipụta arụmọrụ: 6-8 inch semi-insulating SiC: slicing time 10-15 nkeji / wafer; ihe onwunwe ọnwụ <30 μm6-8 inch conductive SiC: slicing oge 14-20 nkeji / wafer; ihe efu <60 μm

Atụmatụ mkpụrụ wafer ririla ihe karịrị 50%

Mgbe emechara slicing, wafers na-ezute ụkpụrụ mba maka geometry ka egweri na polishing. Nnyocha na-egosikwa na mmetụta okpomọkụ na-akpata laser adịghị emetụta nrụgide ma ọ bụ geometry na wafers.

A na-ejikwa otu ngwa ahụ iji chọpụta na ọ ga-ekwe omume ịkpụ diamond, GaN, na Ga₂O₃ otu kristal.

Oge nzipu: Mee-23-2025