Okwu mmalite nke silicon carbide

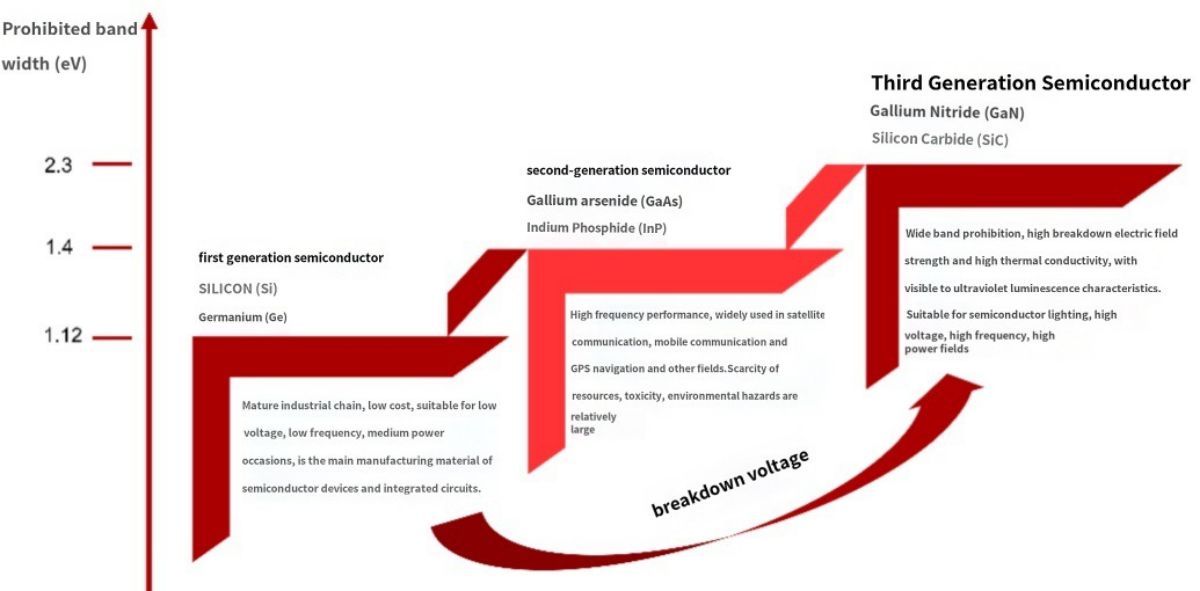

Silicon carbide (SiC) bụ ihe mejupụtara semiconductor ihe mejupụtara carbon na silicon, nke bụ otu n'ime ihe kachasị mma maka ịme okpomọkụ dị elu, ugboro ugboro, ike dị elu na ngwaọrụ voltaji dị elu. E jiri ya tụnyere ihe siliki ọdịnala (Si), oghere nke silicon carbide bụ okpukpu atọ nke silicon. The thermal conductivity bụ 4-5 ugboro nke silicon; Voltaji ndakpọ bụ 8-10 ugboro nke silicon; Ọnụego saturation elektrọnik bụ 2-3 ugboro nke silicon, nke na-egbo mkpa nke ụlọ ọrụ ọgbara ọhụrụ maka ike dị elu, voltaji dị elu na ugboro dị elu. A na-eji ya eme ihe maka imepụta ngwa ngwa ngwa ngwa, ngwa ngwa dị elu, ike dị elu na ọkụ eletrik. Ogige ngwa nke ala na-agụnye grid smart, ụgbọ ala ume ọhụrụ, ike ikuku fotovoltaic, nkwurịta okwu 5G, wdg. Silicon carbide diodes na MOSFETs ka etinyere n'ahịa.

Nnukwu okpomọkụ na-eguzogide. The band ọdịiche obosara nke silicon carbide bụ 2-3 ugboro nke silicon, ndị electrons adịghị mfe mgbanwe na elu okpomọkụ, na ike idi elu arụ ọrụ okpomọkụ, na thermal conductivity nke silicon carbide bụ 4-5 ugboro nke silicon, na-eme ka ngwaọrụ okpomọkụ dissipation mfe na njedebe na-arụ ọrụ okpomọkụ elu. Mgbochi okpomọkụ dị elu nwere ike ịbawanye njupụta ike nke ukwuu mgbe ị na-ebelata ihe ndị a chọrọ na sistemu jụrụ oyi, na-eme ka njedebe dị ọkụ ma dị ntakịrị.

Nagide nrụgide dị elu. Ike mgbawa eletrik nke silicon carbide bụ okpukpu 10 nke silicon, nke nwere ike iguzogide voltaji dị elu ma dabara adaba maka ngwaọrụ voltaji dị elu.

Nnukwu nguzogide ugboro ugboro. Silicon carbide nwere ọnụọgụ eletrọn juru eju ugboro abụọ nke silicon, na-ebute enweghị ọdụ ọdụ ugbu a n'oge usoro mmechi ahụ, nke nwere ike imeziwanye mgbanwe ngbanwe nke ngwaọrụ ahụ nke ọma wee ghọta miniaturization nke ngwaọrụ ahụ.

Ọnwụ ike dị ala. E jiri ya tụnyere ihe silicon, silicon carbide nwere obere nguzogide yana obere mfu. N'otu oge ahụ, obosara band-ọpụpụ nke silicon carbide na-ebelata nke ukwuu ntapu nke ugbu a na mfu ike. Tụkwasị na nke ahụ, ngwaọrụ silicon carbide enweghị ihe na-eme n'azụ ugbu a n'oge usoro nkwụsị, na ngbanwe mgbanwe dị ala.

Silicon carbide yinye ụlọ ọrụ

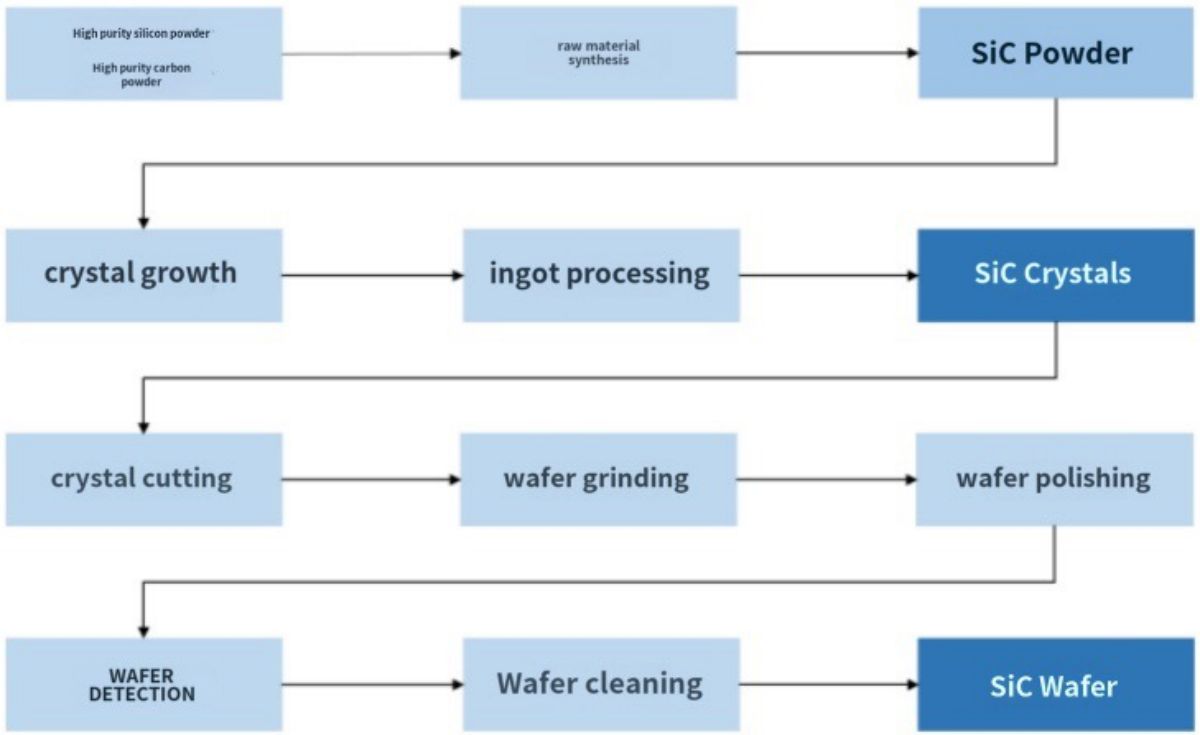

Ọ na-agụnyekarị mkpụrụ, epitaxy, imewe ngwaọrụ, nrụpụta, akara na ihe ndị ọzọ. Silicon carbide sitere na ihe ahụ gaa na ngwaọrụ ike semiconductor ga-enweta otu uto kristal, slicing ingot, uto epitaxial, imepụta wafer, nrụpụta, nkwakọ ngwaahịa na usoro ndị ọzọ. Mgbe njikọ nke silicon carbide ntụ ntụ gasịrị, a na-ebu ụzọ mee silicon carbide ingot, mgbe ahụ, a na-enweta mkpụrụ osisi silicon carbide site na slicing, na-egweri na polishing, na epitaxial mpempe akwụkwọ na-enweta site na epitaxial ibu. Epitaxial wafer bụ nke silicon carbide site na lithography, etching, implantation ion, metal passivation na usoro ndị ọzọ, a na-egbutu wafer ahụ na-anwụ anwụ, a na-ejikọta ngwaọrụ ahụ, na-ejikọta ngwaọrụ ahụ n'ime shei pụrụ iche ma gbakọta n'ime modul.

Upstream nke ụlọ ọrụ yinye 1: mkpụrụ - kristal uto bụ isi usoro njikọ

Mkpụrụ silicon carbide na-akwụ ihe dị ka 47% nke ọnụ ahịa ngwaọrụ silicon carbide, ihe mgbochi teknụzụ kachasị elu, ọnụ ahịa kachasị ukwuu, bụ isi nke nrụpụta nnukwu ụlọ ọrụ SiC n'ọdịnihu.

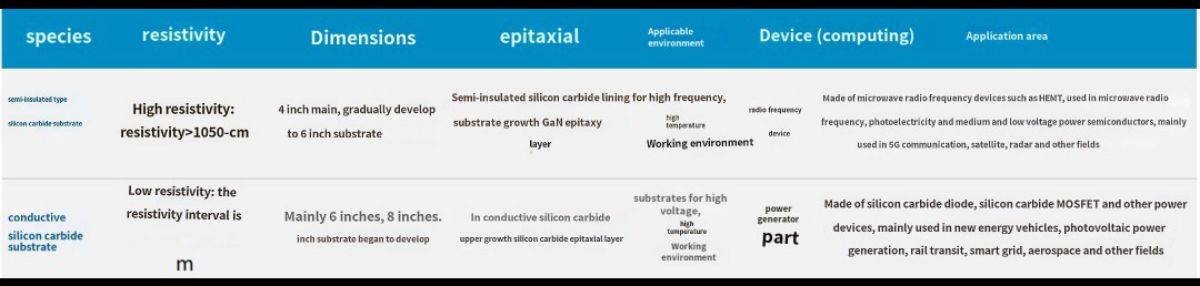

Site n'echiche nke electrochemical Njirimara iche, silicon carbide mkpụrụ ihe nwere ike kewaa conductive substrates (resistivity mpaghara 15 ~ 30mΩ · cm) na ọkara mkpuchi ihe substrates (resistivity elu karịa 105Ω · cm). A na-eji ụdị ihe abụọ a na-emepụta ngwaọrụ pụrụ iche dị ka ngwaọrụ ike na ngwaọrụ ugboro redio n'otu n'otu mgbe uto epitaxial gasịrị. N'ime ha, mkpụrụ osisi silicon carbide nwere obere mkpuchi bụ nke a na-ejikarị na-emepụta ngwaọrụ gallium nitride RF, ngwaọrụ fotoelectric na ndị ọzọ. Site na itolite gan epitaxial oyi akwa na obere mkpuchi SIC, a na-akwado efere sic epitaxial, nke enwere ike ịkwado ya na ngwaọrụ HEMT gan iso-nitride RF. A na-ejikarị mkpụrụ osisi silicon carbide na-arụ ọrụ na-emepụta ngwaọrụ ike. Dị iche na usoro nrụpụta ike silicon nke ọdịnala, enweghị ike ịme ngwaọrụ silicon carbide ozugbo na mkpụrụ osisi silicon carbide, silicon carbide epitaxial Layer kwesịrị tolite na mkpụrụ ihe na-eduzi iji nweta mpempe akwụkwọ silicon carbide epitaxial, a na-emepụta akwa epitaxial na Schottky diode, MOSFET, IGBT na ngwaọrụ ike ndị ọzọ.

Silicon carbide ntụ ntụ bụ synthesized si elu ịdị ọcha carbon ntụ ntụ na elu ịdị ọcha silicon ntụ ntụ, na dị iche iche size nke silicon carbide ingot toro n'okpuru pụrụ iche okpomọkụ ubi, na mgbe ahụ silicon carbide mkpụrụ e mepụtara site multiple nhazi usoro. Isi usoro gụnyere:

Ngwakọta ihe ọkụkụ: A na-agwakọta silicon ntụ ntụ + toner dị elu dị ka usoro ahụ si dị, a na-eme mmeghachi omume ahụ n'ime ụlọ mmeghachi omume n'okpuru ọnọdụ okpomọkụ dị elu n'elu 2000 Celsius C iji mejupụta mkpụrụ osisi silicon carbide nwere ụdị kristal kpọmkwem na nha nha. Mgbe ahụ site na ngwepịa, nyocha, ihicha na usoro ndị ọzọ, iji mezuo ihe achọrọ nke nnukwu ihe dị ọcha silicon carbide ntụ ntụ.

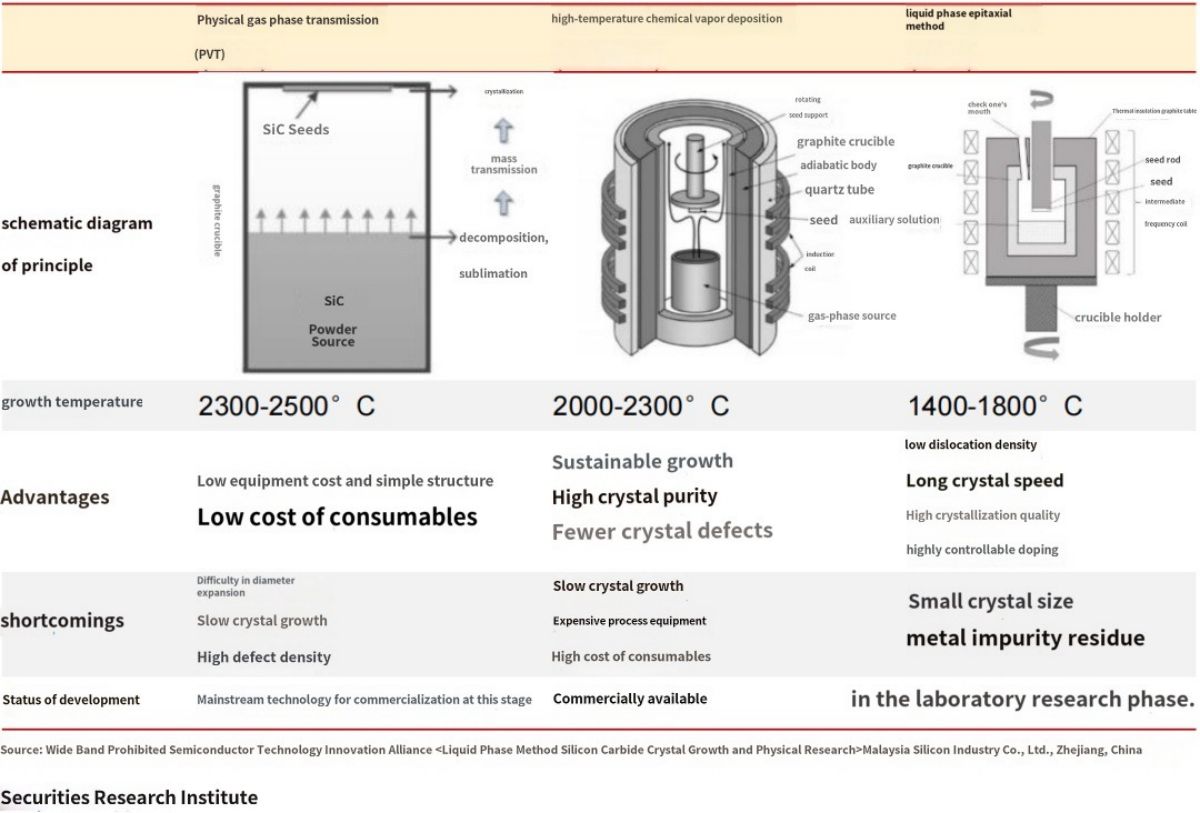

Uto kristal bụ usoro bụ isi nke imepụta mkpụrụ osisi silicon carbide, nke na-ekpebi njirimara eletriki nke mkpụrụ osisi silicon carbide. Ka ọ dị ugbu a, ụzọ bụ isi maka uto kristal bụ mbufe ikuku anụ ahụ (PVT), nnukwu ikuku mmiri kemịkalụ (HT-CVD) na epitaxy nke mmiri mmiri (LPE). N'ime ha, usoro PVT bụ usoro bụ isi maka uto azụmahịa nke mkpụrụ osisi SiC ugbu a, yana ntozu teknụzụ kachasị elu yana nke a na-ejikarị na injinia.

Nkwadebe nke mkpụrụ osisi SiC siri ike, na-eduga na ọnụ ahịa ya dị elu

Okpomọkụ ubi akara siri ike: Si kristal mkpara ibu naanị mkpa 1500 ℃, mgbe SiC crystal mkpanaka kwesịrị toro na a elu okpomọkụ n'elu 2000 ℃, na e nwere ihe karịrị 250 SiC isomers, ma isi 4H-SiC otu kristal Ọdịdị maka mmepụta nke ike ngwaọrụ, ma ọ bụrụ na ọ bụghị kpọmkwem akara, ga-enweta ndị ọzọ kristal owuwu. Ke adianade do, okpomọkụ gradient na crucible na-ekpebi ọnụego nke SiC sublimation nyefe na ndokwa na uto mode nke gaseous atọm na crystal interface, nke na-emetụta kristal ibu ọnụego na crystal àgwà, n'ihi ya, ọ dị mkpa na-etolite a Ịhazi okpomọkụ ubi akara technology. E jiri ya tụnyere ihe Si, ihe dị iche na mmepụta SiC dịkwa na usoro okpomọkụ dị elu dị ka ntinye ion dị elu, ikpo ọkụ dị elu, ọkụ ọkụ dị elu, na usoro nkpuchi siri ike chọrọ nke usoro okpomọkụ ndị a dị elu.

Ọganihu kristal dị nwayọ: ọnụ ọgụgụ uto nke mkpanaka kristal Si kristal nwere ike iru 30 ~ 150mm / h, na mmepụta nke mkpanaka kristal silicon 1-3m na-ewe naanị otu ụbọchị; Mkpanaka kristal SiC na usoro PVT dị ka ihe atụ, ọnụ ọgụgụ na-eto eto bụ ihe dịka 0.2-0.4mm / h, ụbọchị 7 na-eto eto na-erughị 3-6cm, ọnụ ọgụgụ na-eto eto na-erughị 1% nke ihe silicon, ikike mmepụta dị oke oke.

Elu ngwaahịa parameters na ala mkpụrụ: isi parameters nke SiC mkpụrụ na-agụnye microtubule njupụta, dislocation njupụta, resistivity, warpage, elu roughness, wdg Ọ bụ a mgbagwoju usoro engineering ndokwa atọm na a mechiri emechi elu-okpomọkụ ụlọ na zuru ezu crystal ibu, mgbe ịchịkwa oke indexes.

Ihe ahụ nwere ike dị elu, nnukwu brittleness, ogologo oge ịkpụ na akwa akwa: SiC Mohs hardness nke 9.25 bụ nke abụọ na diamond, nke na-eduga n'ịbawanyewanye n'ihe isi ike nke ịkpụ, ichikota na polishing, ọ na-ewe ihe dị ka awa 120 iji bee 35-40 iberibe 35cm oké ingot. Na mgbakwunye, n'ihi nnukwu brittleness nke SiC, uwe nhazi wafer ga-abụ karịa, na mmepụta mmepụta bụ naanị ihe dịka 60%.

Usoro mmepe: Mmụba nha + mbelata ọnụ ahịa

Ahịa SiC zuru ụwa ọnụ 6-anụ ọhịa mmepụta ahịrị na-eto eto, ụlọ ọrụ ndị isi abanyela n'ahịa 8-inch. Ọrụ mmepe ụlọ bụ nke kachasị inch isii. Ka ọ dị ugbu a, ọ bụ ezie na ọtụtụ ụlọ ọrụ ụlọ ka na-adabere na ahịrị mmepụta 4-inch, mana ụlọ ọrụ ahụ na-eji nwayọọ nwayọọ na-agbasa ruo 6-inch, na ntozu nke 6-inch na-akwado teknụzụ akụrụngwa, teknụzụ mkpụrụ ụlọ SiC na-eji nwayọọ nwayọọ na-emeziwanye akụ na ụba nke ọnụ ọgụgụ nnukwu ahịrị mmepụta ihe ga-egosipụta, na oghere oge mmepụta anụ ọhịa 6-inch dị ugbu a agbadala ruo afọ 7. Oke wafer buru ibu nwere ike iweta mmụba nke ọnụ ọgụgụ nke otu ibe, melite ọnụego mkpụrụ, ma belata oke nke ibe, na ọnụ ahịa nyocha na mmepe na mfu mkpụrụ ga-edobe ihe dị ka 7%, si otú a na-emeziwanye ojiji wafer.

A ka nwere ọtụtụ ihe isi ike na nhazi ngwaọrụ

A na-eji nwayọọ nwayọọ na-emewanyewanye ahịa nke SiC diode, ugbu a, ọtụtụ ndị na-emepụta ụlọ emebela ngwaahịa SiC SBD, ngwaahịa SiC SBD dị elu na nke dị elu nwere nkwụsi ike dị mma, n'ime ụgbọ ala OBC, ojiji nke SiC SBD + SI IGBT iji nweta njupụta dị ugbu a. Ka ọ dị ugbu a, ọ nweghị ihe mgbochi na nhazi patent nke ngwaahịa SiC SBD na China, na ọdịiche dị na mba ndị ọzọ dị ntakịrị.

SiC MOS ka nwere ọtụtụ ihe isi ike, a ka nwere ọdịiche dị n'etiti SiC MOS na ndị na-emepụta esenidụt, a ka na-arụkwa usoro mmepụta ihe dị mkpa. Ugbu a, ST, Infineon, Rohm na ndị ọzọ 600-1700V SiC MOS enwetawo uka mmepụta na bịanyere aka na Ship na ọtụtụ n'ichepụta ụlọ ọrụ, mgbe ugbu a anụ ụlọ SiC MOS imewe e ihu ọma dechara, a ọnụ ọgụgụ nke imewe emepụta na-arụ ọrụ na fabs na wafer eruba ogbo, na mgbe e mesịrị ahịa nkwenye ka chọrọ oge ụfọdụ, n'ihi ya, a ka nwere ogologo oge azụmahịa.

Ka ọ dị ugbu a, nhazi atụmatụ bụ isi nhọrọ, na ụdị trenchi a na-ejikarị eme ihe n'ọhịa dị elu n'ọdịnihu. Ndị na-emepụta atụmatụ SiC MOS dị ọtụtụ, usoro nhazi ahụ adịghị mfe ịmepụta nsogbu mmebi mpaghara ma e jiri ya tụnyere oghere, na-emetụta nkwụsi ike nke ọrụ ahụ, na ahịa dị n'okpuru 1200V nwere ọtụtụ uru ngwa ngwa, na nhazi atụmatụ dị mfe na njedebe mmepụta, iji zute nrụpụta na njikwa ọnụ ahịa akụkụ abụọ. The groove ngwaọrụ nwere uru nke kemgwucha ala parasitic inductance, ngwa ngwa ịmafe ọsọ, ala ọnwụ na dịtụ elu arụmọrụ.

2--SiC wafer ozi

Mmepụta ahịa silicon carbide na uto ahịa, ṅaa ntị na ahaghị nhata n'etiti ọkọnọ na ọchịchọ

Site na uto ngwa ngwa nke ahịa ahịa maka ngwa elektrọnik dị elu na ike dị elu, njedebe anụ ahụ nke ngwaọrụ semiconductor dabere na silicon ejirila nke nta nke nta bụrụ nke ama ama, na ihe semiconductor nke ọgbọ nke atọ nke silicon carbide (SiC) nọchiri anya ya ejirila nwayọọ nwayọọ bụrụ ụlọ ọrụ mmepụta ihe. Site na ele ihe anya arụmọrụ, silicon carbide nwere 3 ugboro band ọdịiche obosara nke silicon ihe onwunwe, 10 ugboro dị oké egwu mmebi eletrik eletrik ike ubi, 3 ugboro thermal conductivity, otú silicon carbide ike ngwaọrụ adabara elu ugboro, elu mgbali, elu okpomọkụ na ngwa ndị ọzọ, nyere aka melite arụmọrụ na ike njupụta nke ike electronic usoro.

Ka ọ dị ugbu a, SiC diodes na SiC MOSFET ji nwayọọ nwayọọ kwaga n'ahịa, na e nwere ọtụtụ ngwaahịa ndị tozuru okè, n'etiti nke SiC diodes na-eji ọtụtụ ebe kama silicon dabeere diodes na ụfọdụ ubi n'ihi na ha enweghị uru nke azụ mgbake ụgwọ; A na-ejikwa SiC MOSFET nke nta nke nta na ụgbọ ala, nchekwa ike, ikpo ọkụ, fotovoltaic na ubi ndị ọzọ; N'ọhịa nke ngwa ụgbọ ala, omume nke modularization na-aghọwanye nke a ma ama, arụmọrụ kachasị elu nke SiC kwesịrị ịdabere na usoro nkwakọ ngwaahịa dị elu iji nweta, teknụzụ na-eji akara mkpuchi dịtụ tozuru oke dị ka isi, ọdịnihu ma ọ bụ na mmepe nke plastik, njirimara mmepe ahaziri ya dabara adaba maka modul SiC.

Ọnụ ahịa silicon carbide na-agbada ọsọ ọsọ ma ọ bụ karịa n'echiche

Ngwa nke silicon carbide ngwaọrụ bụ tumadi oke site na ọnụ ahịa dị elu, ọnụ ahịa nke SiC MOSFET n'okpuru otu ọkwa bụ 4 ugboro elu karịa nke Si dabeere IGBT, nke a bụ n'ihi na usoro nke silicon carbide bụ mgbagwoju, nke uto nke otu kristal na epitaxial bụghị nanị ike na gburugburu ebe obibi, kamakwa uto ọnụego bụ ngwa ngwa, na otu kristal nhazi n'ime mkpụrụ ga-aga site n'igbu na usoro. Dabere na njirimara ihe onwunwe ya na teknụzụ nhazi akabeghị aka, mkpụrụ nke mkpụrụ ụlọ na-erughị 50%, na ihe dị iche iche na-eduga ná nnukwu mkpụrụ na ọnụ ahịa epitaxial.

Otú ọ dị, ọnụ ahịa mejupụtara silicon carbide ngwaọrụ na silicon dabeere ngwaọrụ bụ diametrically megidere, na mkpụrụ na epitaxial na-akwụ ụgwọ nke n'ihu ọwa akaụntụ maka 47% na 23% nke dum ngwaọrụ n'otu n'otu, ngụkọta banyere 70%, ngwaọrụ imewe, n'ichepụta na akara njikọ nke azụ ọwa akaụntụ maka naanị 30%, mmepụta na-eri nke silicon dabeere na ngwaọrụ bụ isi ihe na-azụta 5% n'ichepụta na ọwa nke 5% n'ichepụta. ọnụ ahịa ya bụ naanị 7%. Ihe omume nke uru nke ụlọ ọrụ silicon carbide yinye gbadoro ụkwụ na-egosi na ndị na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe nwere ikike ikwu okwu, nke bụ isi ihe na nhazi nke ụlọ ọrụ ụlọ na nke mba ọzọ.

Site n'echiche siri ike na ahịa, ibelata ọnụ ahịa silicon carbide, na mgbakwunye na ịkwalite silicon carbide ogologo kristal na usoro slicing, bụ ịgbasa nha wafer, nke bụkwa ụzọ tozuru oke nke mmepe semiconductor n'oge gara aga, data Wolfspeed na-egosi na mkpụrụ osisi silicon carbide kwalite site na sentimita 6 ruo 8 sentimita asatọ, mmepụta mgbawa ruru eru nwere ike ịbawanye site na 80% -90. Nwere ike ibelata ọnụ ahịa nkeji jikọtara ọnụ site na 50%.

2023 a maara dị ka "8-inch SiC afọ mbụ", afọ a, anụ ụlọ na mba ọzọ silicon carbide emepụta na-eme ngwangwa okirikiri nhọrọ ukwuu nke 8-inch silicon carbide, dị ka Wolfspeed crazy itinye ego nke 14.55 ijeri US dollar maka silicon carbide mmepụta mgbasa, akụkụ dị mkpa nke na-ewu nke 8-inch SiC substrate ụlọ ọrụ, Iji hụ na ọdịnihu ga-eweta nke SiC substrate ụlọ ọrụ, iji hụ na ọdịnihu na-eweta a ọnụ ọgụgụ nke SiC metal ụlọ ọrụ. Domestic Tianyue Advanced na Tianke Heda abịanyela aka na Infineon nkwekọrịta ogologo oge iji weta 8-inch silicon carbide substrates n'ọdịnihu.

Malite na afọ a, silicon carbide ga ngwangwa si 6 sentimita asatọ na 8 sentimita asatọ, Wolfspeed na-atụ anya na site na 2024, na unit mgbawa na-eri nke 8 sentimita mkpụrụ tụnyere unit mgbawa na-eri nke 6 sentimita mkpụrụ na 2022 ga-ebelata ihe karịrị 60%, na ọnụ ibelata ga-ọzọ na-emeghe ngwa ahịa, Ji Bond Consulting nnyocha data kwuru. Oke ahịa nke ngwaahịa inch 8 dị ugbu a erughị 2%, a na-atụkwa anya na oke ahịa ga-eto ruo ihe dịka 15% site na 2026.

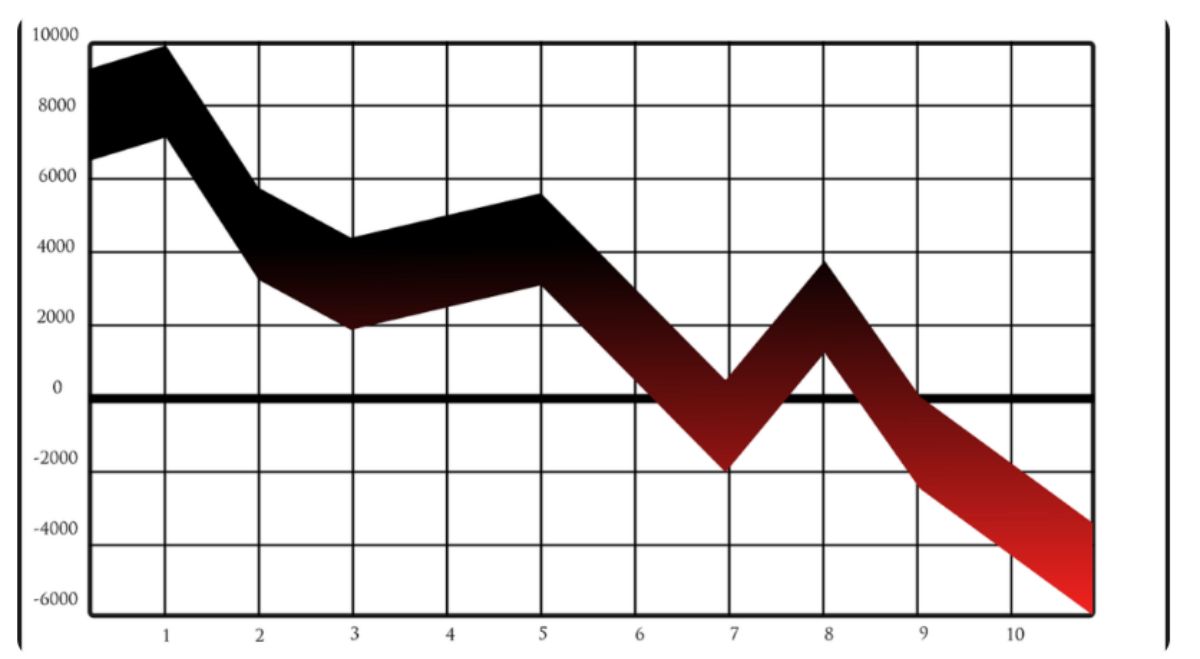

N'ezie, ọnụ ọgụgụ nke ọdịda na price nke silicon carbide mkpụrụ nwere ike gafere ọtụtụ ndị mmadụ pụrụ ichetụ n'echiche, ugbu a ahịa na-enye nke 6-anụ ọhịa mkpụrụ bụ 4000-5000 yuan / ibe, tụnyere na mmalite nke afọ dara a otutu, a na-atụ anya na-ada n'okpuru 4000 yuan n'afọ ọzọ, ọ bụ ihe kwesịrị ịrịba ama na ụfọdụ ndị na-emepụta ihe na-eme ka a mara na ụfọdụ ndị na-emepụta ihe na-ebelata ọnụ ahịa nke mbụ n'okpuru ọnụ ahịa nke Open ahịa, na-ebelata ọnụahịa ahịa n'okpuru ọnụ ahịa ahịa. agha, tumadi lekwasịrị na silicon carbide mkpụrụ ọkọnọ a dịtụ ezuru na ala voltaji ubi, anụ ụlọ na mba ọzọ na-emepụta na-akpa ike na-agbasa mmepụta ike, ma ọ bụ ka silicon carbide substrate oversupply ogbo tupu ka e chere.

Oge nzipu: Jan-19-2024