Silicon carbide (SiC) abụghị naanị teknụzụ dị oke egwu maka nchekwa mba kamakwa ihe dị mkpa maka ụlọ ọrụ ụgbọ ala na ike zuru ụwa ọnụ. Dị ka nzọụkwụ mbụ dị oke mkpa na nhazi otu-kristal SiC, slicing wafer na-ekpebi kpọmkwem ịdị mma nke ịchafụ na nchacha. Ụzọ slicing omenala na-ebutekarị mgbawa elu na n'okpuru ala, na-abawanye ọnụego nkwụsịtụ wafer na ọnụ ahịa nrụpụta. Ya mere, ịchịkwa mmebi mgbawa elu dị mkpa maka ịkwalite nrụpụta ngwaọrụ SiC.

Ugbu a, slicing SiC ingot na-eche nnukwu ihe ịma aka abụọ ihu:

- Mfu ihe dị elu na ịwa osisi ọtụtụ waya:SiC siri ike na mgbakasị ahụ na-eme ka ọ na-enwe ike ịgbawa na mgbawa n'oge ịkpụ, egweri, na polishing. Dị ka data Infineon si kwuo, ịhịarị ọtụtụ waya na-emeghachite diamond resin-bonded na-enweta naanị 50% iji ihe eji egbutu, yana mfu otu-wafer na-eru ~ 250 μm mgbe emechara ya, na-ahapụ obere ihe eji eme ihe.

- Obere arụmọrụ na ogologo usoro mmepụta ihe:Ọnụ ọgụgụ mmepụta mba ụwa na-egosi na ịmepụta 10,000 wafers na-eji 24-hour na-aga n'ihu n'ọtụtụ waya na-ewe ~ 273 ụbọchị. Usoro a na-achọ nnukwu akụrụngwa na ihe eji eme ihe mgbe ọ na-eme ka ọ dị elu na mmetọ (uzuzu, mmiri mkpofu).

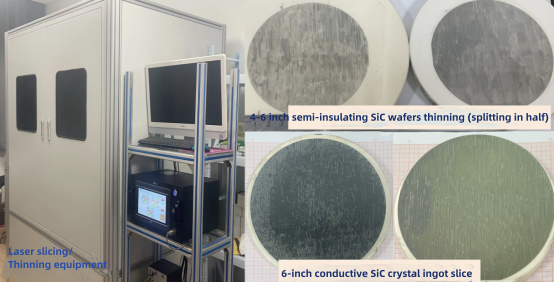

Iji lebara okwu ndị a anya, ndị otu Prọfesọ Xiu Xiangqian na Mahadum Nanjing ewepụtala akụrụngwa slicing laser dị elu maka SiC, na-eji teknụzụ laser ultrafast iji belata ntụpọ na ịkwalite nrụpụta. Maka ingot SiC 20mm, teknụzụ a na-eme ka mkpụrụ wafer dị okpukpu abụọ ma e jiri ya tụnyere ịwa waya ọdịnala. Na mgbakwunye, wafers ndị e sliced laser na-egosipụta otu ọdịdị geometric dị elu, na-eme ka mbelata ọkpụrụkpụ ruo 200 μm kwa wafer ma na-abawanye mmepụta.

Uru ndị isi:

- R&D emechara na ngwa ihe nlebanya buru ibu, nke akwadoro maka igburi 4–6-inch semi-insulating SiC wafers na 6-inch conductive SiC ingots.

- 8-inch ingot slicing nọ n'okpuru nkwenye.

- Oge mkpirisi dị mkpụmkpụ nke ukwuu, mmepụta kwa afọ dị elu, yana> 50% nkwalite mkpụrụ.

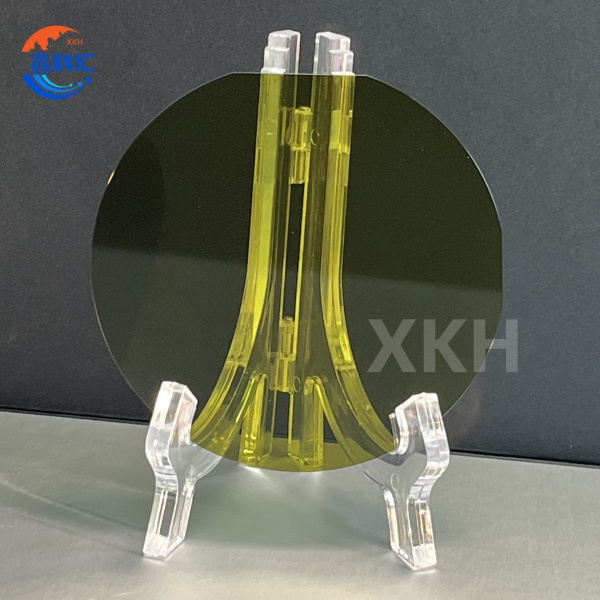

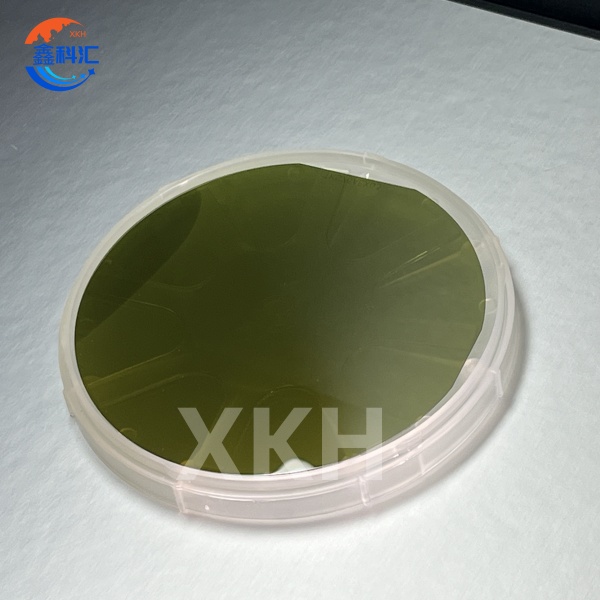

Mkpụrụ SiC nke XKH nke ụdị 4H-N

Nwere ike ahịa:

Ngwá ọrụ a dị njikere ịghọ isi ihe ngwọta maka 8-inch SiC ingot slicing, nke ndị Japan na-ebubata ugbu a nwere ọnụ ahịa dị elu na mgbochi mbupụ. Ọchịchọ ụlọ maka akụrụngwa slicing/mhịhịa laser karịrị nkeji 1,000, mana enweghị ụzọ ọzọ ndị China mere tozuru oke adị. Teknụzụ Mahadum Nanjing nwere nnukwu uru ahịa yana ikike akụ na ụba.

Ndakọrịta ọtụtụ ihe:

Na agafe SiC, akụrụngwa na-akwado nhazi laser nke gallium nitride (GaN), aluminom oxide (Al₂O₃), na diamond, na-agbasa ngwa ngwa ụlọ ọrụ ya.

Site n'ịgbanwe nhazi SiC wafer, ihe ọhụrụ a na-eleba anya n'ihe mgbochi dị oke mkpa na nrụpụta semiconductor ka ọ na-adakọ na usoro zuru ụwa ọnụ maka ịrụ ọrụ dị elu, ihe na-arụ ọrụ ike.

Mmechi

Dị ka onye isi ụlọ ọrụ na silicon carbide (SiC) mmepụta mkpụrụ, XKH na-ahụ maka inye 2-12-inch zuru oke SiC substrates (gụnyere 4H-N / SEMI-ụdị, 4H / 6H / 3C-ụdị) ahaziri na elu-eto eto dị ka ọhụrụ ume ugbo ala (NEVs), photovoltaic 5G nchekwa nchekwa, fotovoltaic. N'iji teknụzụ slicing dị ala na-efunahụ nnukwu akụkụ, yana teknụzụ nhazi dị elu, anyị enwetala nnukwu mmepụta nke 8-inch substrates na ihe ịga nke ọma na teknụzụ uto SiC kristal 12-inch na-eduzi, na-ebelata ọnụ ahịa mgbawa kwa otu. N'ịga n'ihu, anyị ga-aga n'ihu na-ebuli slicing laser ọkwa ingot na usoro nchịkwa nchekasị nke ọgụgụ isi iji bulie mkpụrụ osisi 12-inch na ọkwa asọmpi zuru ụwa ọnụ, na-enye ụlọ ọrụ SiC ike imebi ikike mba ụwa ma mee ngwa ngwa ngwa ngwa na ngalaba dị elu dị ka ibe-ọkwa ụgbọ ala na ihe nkesa AI.

Mkpụrụ SiC nke XKH nke ụdị 4H-N

Oge nzipu: Ọgọst-15-2025