Kemgbe 1980s, njupụta njupụta nke sekit eletrọnịkị na-abawanye na ọnụego kwa afọ nke 1.5 × ma ọ bụ ngwa ngwa. Njikọ dị elu na-eduga n'ịdị ukwuu dị ugbu a na mmepụta okpomọkụ n'oge ọrụ.Ọ bụrụ na agbasaghị nke ọma, okpomọkụ a nwere ike ime ka okpomọkụ ghara ịda mbà ma belata oge ndụ nke ngwa eletriki.

Iji gboo mkpa njikwa okpomọkụ na-arị elu, a na-enyocha ma na-emeziwanye ihe nkwakọ ngwaahịa eletrọnịkị dị elu nwere arụmọrụ ọkụ dị elu.

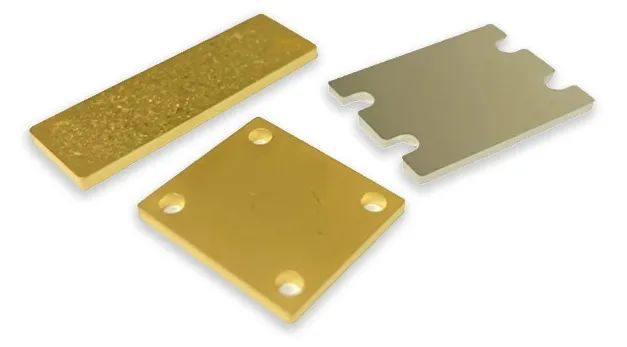

Ihe mejupụtara diamond/ọla kọpa

01 diamond na ọla kọpa

Ihe nkwakọ ngwaahịa ọdịnala gụnyere ceramik, rọba, ọla, na alloys ha. Ceramics dị ka BeO na AlN na-egosipụta CTE ndị semiconductor dabara adaba, nkwụsi ike kemịkalụ dị mma, yana ikuku ọkụ na-agafeghị oke. Agbanyeghị, nhazi ha gbagwojuru anya, ọnụ ahịa dị elu (karịsịa BeO na-egbu egbu), yana ngwa oke na-emebi emebi. Nkwakọ ngwaahịa rọba na-enye ọnụ ala dị ala, ịdị arọ dị mfe, yana mkpuchi mana ọ na-enwe mmetụta na-adịghị mma nke okpomọkụ yana enweghị oke okpomọkụ. Ọla dị ọcha (Cu, Ag, Al) nwere conductivity thermal dị elu mana oke CTE, ebe alloys (Cu-W, Cu-Mo) na-emebi arụmọrụ ọkụ. Ya mere, ihe nkwakọ ngwaahịa akwụkwọ akụkọ na-edozi ịdị elu thermal conductivity na ezigbo CTE dị mkpa ngwa ngwa.

| Nkwanye | Nrụpụta ọkụ (W/(m·K)) | CTE (×10⁻⁶/℃) | Njupụta (g/cm³) |

| diamond | 700-2000 | 0.9–1.7 | 3.52 |

| Ahụhụ BeO | 300 | 4.1 | 3.01 |

| Akụkụ AlN | 150–250 | 2.69 | 3.26 |

| Akụkụ SiC | 80–200 | 4.0 | 3.21 |

| B₄ ụmụ irighiri ihe | 29–67 | 4.4 | 2.52 |

| eriri boron | 40 | ~5.0 | 2.6 |

| Ihe ndị TiC | 40 | 7.4 | 4.92 |

| Al₂O₃ ụmụ irighiri ihe | 20–40 | 4.4 | 3.98 |

| SiC ntụ ntụ | 32 | 3.4 | - |

| Si₃N₄ ahụ | 28 | 1.44 | 3.18 |

| TiB₂ ahụ | 25 | 4.6 | 4.5 |

| SiO₂ ahụ | 1.4 | <1.0 | 2.65 |

diamond, ihe okike kacha sie ike mara (Mohs 10), nwekwara ihe pụrụ icheconductivity okpomọkụ (200-2200 W / (m·K)).

Obere ntụ ntụ diamond

Ọla kọpa, ya na elu thermal/electrical conductivity (401 W / (m·K)), ductility, na ọnụ ahịa arụmọrụ, na-eji ọtụtụ ebe na ICs.

Na-ejikọta akụrụngwa ndị a,diamond/ọla kọpa (Dia/Cu) mejupụtara-ya na Cu dị ka matriks na diamond dị ka nkwado-na-apụta dị ka ihe njikwa ọkụ na-esote ọgbọ.

02 Ụzọ nrụpụta isi

Ụzọ ndị a na-ejikarị akwadebe diamond/ọla kọpa gụnyere: ntụ ntụ metallurgy, usoro okpomọkụ dị elu na usoro nrụgide dị elu, usoro mgbaze mmiri mmiri, usoro mgbapụta plasma ntọhapụ, usoro ịgba mmiri oyi, wdg.

Ntụle dị iche iche nkwadebe ụzọ, usoro na Njirimara nke otu urughuru size diamond / ọla kọpa

| Oke | Powder metallurgy | Vacuum Hot-pịa | Spark Plasma Sintering (SPS) | Okpomọkụ dị elu (HPHT) | Oyi fesa nkwụnye ego | Agbaze nbanye |

| Ụdị diamond | MB8 | HFD-D | MB8 | MB4 | PDA | MBD8/HHD |

| Matrix | 99.8% ntụ ntụ | 99.9% electrolytic Cu ntụ ntụ | 99.9% Cu ntụ ntụ | Alloy/dị ọcha Cu ntụ ntụ | Cu ntụ ntụ dị ọcha | Dị ọcha Cu nnukwu / mkpanaka |

| Ngbanwe interface | - | - | - | B, Ti, Si, Cr, Zr, W, Mo | - | - |

| Nha urughuru (μm) | 100 | 106–125 | 100–400 | 20–200 | 35–200 | 50–400 |

| Iberibe olu (%) | 20–60 | 40–60 | 35–60 | 60–90 | 20–40 | 60–65 |

| Okpomọkụ (°C) | 900 | 800–1050 | 880–950 | 1100–1300 | 350 | 1100–1300 |

| Nrụgide (MPa) | 110 | 70 | 40–50 | 8000 | 3 | 1–4 |

| Oge (nkeji) | 60 | 60–180 | 20 | 6–10 | - | 5–30 |

| Njupụta nke ikwu (%) | 98.5 | 99.2–99.7 | - | - | - | 99.4–99.7 |

| Arụmọrụ | ||||||

| Nrụpụta ọkụ kacha mma (W/(m·K)) | 305 | 536 | 687 | 907 | - | 943 |

Usoro ihe mejupụtara Dia/C nkịtị gụnyere:

(1)Powder metallurgy

A na-ejikọta ntụ ntụ diamond/C agwakọta ma mebie ya. Ọ bụ ezie na ọ dị ọnụ ahịa ma dị mfe, usoro a na-ewepụta oke njupụta, microstructures na-adịghị ekwekọ, na oke nlele amachibidoro.

Sintering unit

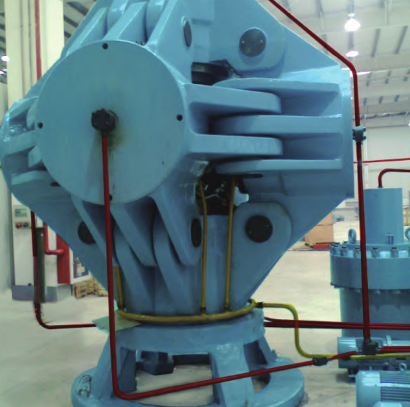

(1)Okpomọkụ dị elu (HPHT)

N'iji igwe nrịbama multi-anvil, Cu a wụrụ awụ na-abanye n'ime lattices diamond n'okpuru ọnọdụ dị oke egwu, na-emepụta ihe mgbagwoju anya. Otú ọ dị, HPHT chọrọ ọkpụkpụ dị oke ọnụ ma ọ dịghị mma maka mmepụta nnukwu.

Cubic pịa

(1)Agbaze nbanye

Molten Cu na-abanye n'ụdị diamond site na ntinye aka na-enyere aka ma ọ bụ nbanye capillary. Ngwakọta ndị na-arụpụta na-enweta> 446 W/(m·K) conductivity thermal.

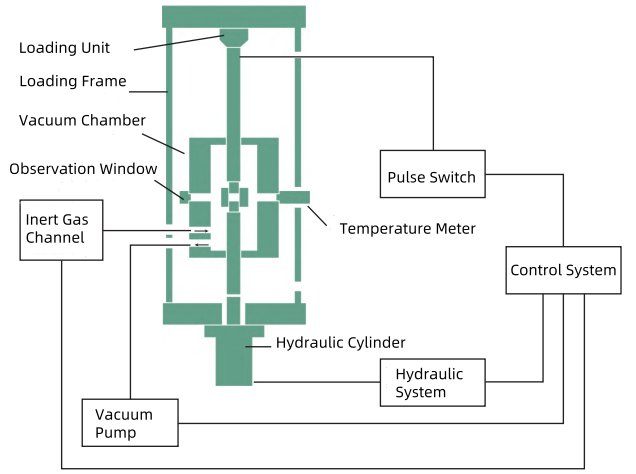

(2)Spark Plasma Sintering (SPS)

Pulsed ugbu a ngwa ngwa sinters agwakọta powders n'okpuru nrụgide. N'agbanyeghị na ọ na-arụ ọrụ nke ọma, arụmọrụ SPS na-eweda ala na akụkụ diamond> 65 vol.

Eserese nke sistemu sistemu plasma na-apụ apụ

(5) Oyi fesa nkwụnye ego

A na-eme ngwa ngwa ma tinye ntụ ọka n'ime mkpụrụ. Usoro a na-amalite na-eche ihe ịma aka ihu na njikwa imecha elu yana nkwenye arụmọrụ ọkụ.

03 Mgbanwe interface

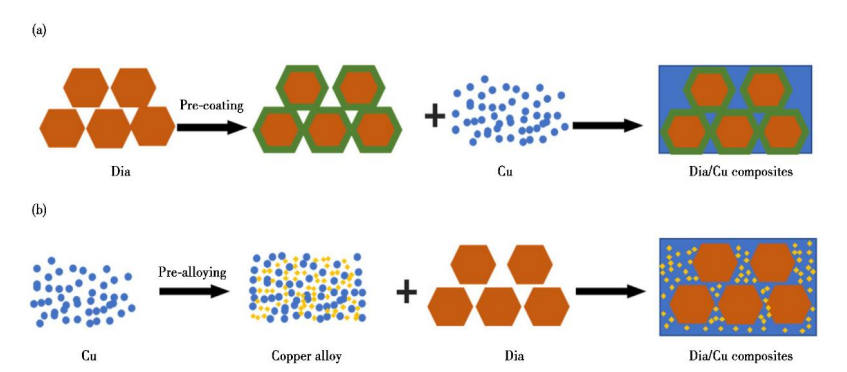

Maka nkwadebe nke ihe ndị mejupụtara, imekọ ihe ọnụ n'etiti ihe ndị dị mkpa bụ ihe dị mkpa maka usoro nhazi na ihe dị mkpa na-emetụta nhazi interface na ọnọdụ njikọ njikọ. Ọnọdụ enweghị mmiri mmiri na interface dị n'etiti diamond na Cu na-eduga na nguzogide okpomọkụ dị elu. Ya mere, ọ dị oke mkpa ịme nyocha mgbanwe na njikọ dị n'etiti abụọ ahụ site na ụzọ ọrụ aka dị iche iche. Ka ọ dị ugbu a, enwere ụzọ abụọ iji meziwanye nsogbu interface dị n'etiti diamond na Cu matrix: (1) Ngwọta mgbanwe ihu igwe nke diamond; (2) Alloying ọgwụgwọ nke ọla kọpa matrix.

Eserese ngbanwe: (a) Ntinye ozugbo n'elu diamond; (b) Matrix alloying

(1) Mgbanwe elu nke diamond

Ịtinye ihe ndị na-arụ ọrụ dị ka Mo, Ti, W na Cr n'elu oyi akwa nke agba agba ume nwere ike melite njirimara interfacial nke diamond, si otú ahụ na-eme ka ọkụ ọkụ ya dịkwuo elu. Sintering nwere ike ime ka ihe ndị dị n'elu meghachi omume na carbon dị n'elu ntụ ntụ diamond iji mepụta oyi akwa mgbanwe carbide. Nke a na-eme ka ọnọdụ wetting dị n'etiti diamond na ntọala ígwè, na mkpuchi nwere ike igbochi nhazi nke diamond ịgbanwe na okpomọkụ dị elu.

(2) Alloying nke ọla kọpa matrix

Tupu nhazi ihe mejupụtara nke ihe, a na-eme ọgwụgwọ tupu ịwa ahụ na ọla kọpa dara, nke nwere ike imepụta ihe ndị mejupụtara ihe mejupụtara ya na n'ozuzu oke ikuku thermal. Doping ihe na-arụ ọrụ na matriks ọla kọpa nwere ike ọ bụghị naanị ibelata wetting Angle n'etiti diamond na ọla kọpa, kamakwa na-emepụta akwa carbide nke siri ike soluble na matrix ọla kọpa na diamond / Cu interface mgbe mmeghachi omume gasịrị. N'ụzọ dị otú a, ọtụtụ n'ime oghere ndị dị na interface ihe onwunwe na-agbanwe ma jupụta, si otú ahụ na-eme ka ọkụ eletrik dịkwuo mma.

04 Nkwubi okwu

Ihe nkwakọ ngwaahịa ọdịnala na-ada obere na ijikwa okpomọkụ sitere na ibe dị elu. Ngwakọta Dia/C, nwere CTE na-emegharị emegharị na ultrahigh thermal conductivity, na-anọchi anya ngwọta mgbanwe maka ngwa eletrọnịkị ọgbọ na-abịa.

Dị ka ụlọ ọrụ teknụzụ dị elu na-ejikọta ụlọ ọrụ na ịzụ ahịa, XKH na-elekwasị anya na nyocha na mmepe na mmepụta nke diamond / ọla kọpa na ihe ndị mejupụtara metal matrix dị elu dị ka SiC / Al na Gr / Cu, na-enye ihe ngwọta nchịkwa ọkụ ọhụrụ na-ekpo ọkụ na okpomọkụ nke n'elu 900W / (m · K) maka ubi nke nkwakọ eletriki na aerospace.

XKH'Ihe mejupụtara ihe mejupụtara ọla kọpa diamond:

Oge nzipu: Mee-12-2025