Seramiiki silicon carbide (SiC) dị ọcha apụtala dị ka ihe dị mma maka ihe ndị dị oke mkpa na semiconductor, ikuku ikuku, na ụlọ ọrụ kemịkalụ n'ihi nrụpụta ọkụ ha pụrụ iche, nkwụsi ike kemịkalụ, na ike igwe. Site n'ịchọwanye mkpa maka ịrụ ọrụ dị elu, ngwaọrụ seramiiki mmetọ dị ala, mmepe nke teknụzụ nkwadebe dị mma na nke nwere ike ịgbatị maka ceramics SiC dị ọcha aghọwo ihe nyocha zuru ụwa ọnụ. Akwụkwọ a na-enyocha usoro nkwadebe dị ugbu a maka ceramics SiC dị ọcha, gụnyere recrystallization sintering, sintering na-enweghị nrụgide (PS), ịpị ọkụ (HP), spark plasma sintering (SPS), na mmepụta ihe mgbakwunye (AM), na-elekwasị anya n'ịtụle usoro nchikota, isi ihe, ihe onwunwe, na ihe ịma aka nke usoro ọ bụla.

Ngwa nke ceramik SiC na ngalaba ndị agha na injinia

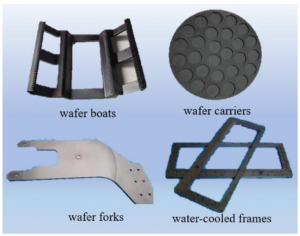

Ugbu a, a na-eji ihe ndị dị na seramiiki SiC dị elu mee ihe na ngwa nrụpụta silicon wafer, na-ekere òkè na usoro isi dị ka oxidation, lithography, etching, na ntinye ion. Site na ọganihu nke teknụzụ wafer, ịba ụba nha wafer aghọwo ihe dị ịrịba ama. Ụdị wafer dị ugbu a bụ 300 mm, na-enweta nguzozi dị mma n'etiti ọnụ ahịa na ikike mmepụta. Otú ọ dị, nke Iwu Moore na-akwalite, mmepụta nke 450 mm wafers abanyelarị na atụmatụ. Wafer ndị buru ibu na-achọkarị ike nhazi dị elu iji guzogide ọgụ na nrụrụ, na-ebutewanye ọchịchọ na-eto eto maka akụkụ seramiiki SiC buru ibu, ike dị elu, dị elu. N'ime afọ ndị na-adịbeghị anya, nrụpụta mgbakwunye (mbipụta 3D), dị ka teknụzụ prototyping ngwa ngwa nke na-achọghị ịkpụzi, egosipụtala ikike dị ukwuu n'ịmepụta akụkụ seramiiki SiC a haziri nke ọma n'ihi nrụpụta oyi akwa ya na ikike imewe na-agbanwe agbanwe, na-adọta nlebara anya zuru ebe niile.

Akwụkwọ a ga-enyocha usoro nkwadebe ise nnọchite anya ise maka ceramics SiC dị ọcha - recrystallization sintering, sintering na-enweghị nrụgide, ịpị ọkụ, spark plasma sintering, na mmepụta ihe mgbakwunye-na-elekwasị anya na usoro nchikota ha, usoro njikarịcha usoro, njirimara arụmọrụ akụrụngwa, na atụmanya ngwa ụlọ ọrụ.

Ngwa ngwa ngwa silicon carbide dị ọcha dị elu chọrọ

I. Recrystallization Sintering

silicon carbide recrystallized (RSiC) bụ ihe SiC dị ọcha dị elu nke a kwadebere na-enweghị ihe enyemaka na-ekpo ọkụ na okpomọkụ dị elu nke 2100-2500ºC. Ebe Fredriksson bu ụzọ chọpụta ihe omume recrystallization na ngwụcha narị afọ nke 19, RSiC enwetala nlebara anya dị ukwuu n'ihi oke ọka ya dị ọcha yana enweghị usoro iko na adịghị ọcha. N'ebe okpomọkụ dị elu, SiC na-egosiputa nrụgide dị elu dị elu, na usoro nkwụsị ya na-agụnye usoro ikpo ọkụ na-ekpo ọkụ: ezigbo ọka na-ekpochapụ ma na-agbanyeghachi n'elu nke ọka buru ibu, na-akwalite uto olu na njikọta kpọmkwem n'etiti ọka, si otú ahụ na-eme ka ike ihe dị elu.

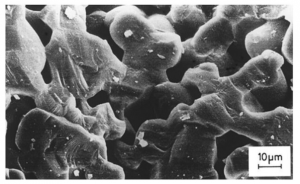

N'afọ 1990, Kriegesmann kwadebere RSiC na njupụta ikwu nke 79.1% na-eji nkedo slip na 2200ºC, na mpaghara obe na-egosi microstructure nke nwere oke ọka na pores. N'ikpeazụ, Yi et al. ejiri ihe nkedo jel kwadoo ahụ ndụ ndụ ndụ wee mee ya na 2450°C, na-enweta ceramik RSiC nwere nnukwu njupụta nke 2.53 g/cm³ yana ike mgbanwe nke 55.4 MPa.

Ihe mgbawa SEM nke RSiC

Tụnyere nnukwu SiC, RSiC nwere njupụta dị ala (ihe dị ka 2.5 g/cm³) yana ihe dị ka 20% mepere emepe, na-amachi arụmọrụ ya na ngwa ike dị elu. Ya mere, imeziwanye njupụta na akụrụngwa nke RSiC abụrụla isi ihe nyocha nyocha. Sung et al. tụrụ aro itinye silicon a wụrụ awụ n'ime carbon / β-SiC agwakọta kọmpat na recrystallizing na 2200 Celsius, na-arụ ọrụ nke ọma n'usoro netwọkụ nke mejupụtara ọka α-SiC. RSiC nke a rụpụtara nwetara njupụta nke 2.7 g/cm³ yana ike mgbanwe nke 134 MPa, na-ejigide nkwụsi ike n'arụ ọrụ na oke okpomọkụ.

Iji kwalite njupụta, Guo et al. eji teknụzụ infiltration polymer na pyrolysis (PIP) maka ọtụtụ ọgwụgwọ RSiC. Iji PCS/xylene ngwọta na SiC/PCS/xylene slurries dị ka infiltrants, mgbe 3-6 PIP cycles, njupụta nke RSiC mere nke ọma (ruo 2.90 g/cm³), yana ike mgbanwe ya. Na mgbakwunye, ha tụrụ aro atụmatụ cyclic na-ejikọta PIP na recrystallization: pyrolysis na 1400 Celsius C na-esote recrystallization na 2400 Celsius C, na-ekpochapụ ihe mgbochi ihe nke ọma na ibelata porosity. Ihe RSiC ikpeazụ nwetara njupụta nke 2.99 g/cm³ yana ike mgbanwe nke 162.3 MPa, na-egosipụta arụmọrụ zuru oke.

Foto SEM nke microstructure evolushọn nke RSiC na-egbu maramara mgbe polymer impregnation na pyrolysis (PIP) - recrystallization cycles: mmalite RSiC (A), mgbe mbụ PIP-recrystallization okirikiri (B), na mgbe nke atọ okirikiri (C)

II. Sintering enweghị nrụgide

A na-akwadokarị seramiki silicon carbide (SiC) na-enweghị nrụgide site na iji ịdị ọcha dị elu, ultrafine SiC ntụ ntụ dị ka akụrụngwa, yana obere ihe enyemaka agbakwunyere, ma tinye ya na ikuku inert ma ọ bụ oghere na 1800-2150 Celsius. Usoro a dabara adaba maka imepụta akụkụ seramiiki a haziri nke ukwuu na nke siri ike. Agbanyeghị, ebe SiC na-ejikọkarị ọnụ, ọnụọgụ mgbasa ozi nke onwe ya dị oke ala, na-eme ka njupụta siri ike na-enweghị ihe enyemaka.

Dabere na usoro nrụgharị ahụ, enwere ike kewaa sintering na-enweghị nrụgide ụzọ abụọ: mmiri mmiri-phase sintering (PLS-SiC) na-enweghị nrụgide (PSS-SiC).

1.1 PLS-SiC (Liquid-phase Sintering)

PLS-SiC na-emekarị sintered n'okpuru 2000 ° C site n'ịgbakwụnye ihe dị ka 10 wt.% nke eutectic sintering aids (dị ka Al₂O₃, CaO, MgO, TiO₂, na obere-earth oxides RE₂O₃) na-etolite a mmiri mmiri, na-akwalite mmezu nke irighiri ihe rearn. Usoro a dabara adaba maka ceramics SiC-ọkwa ụlọ ọrụ, mana enwebeghị akụkọ gbasara SiC dị ọcha nke enwetara site na ntinye mmiri mmiri.

1.2 PSS-SiC (Steetị siri ike)

PSS-SiC na-agụnye njupụta steeti siri ike na okpomọkụ karịrị 2000ºC yana ihe dị ka 1 wt.% nke mgbakwunye. Usoro a na-adabere na mgbasa nke atọm na nhazigharị ọka nke okpomọkụ dị elu na-akwalite iji belata ike elu ma nweta njupụta. Usoro BC (boron-carbon) bụ ngwakọta mgbakwunye a na-ahụkarị, nke nwere ike wedata ike oke ọka wee wepụ SiO₂ na elu SiC. Agbanyeghị, mgbakwunye ọdịnala BC na-ebutekarị adịghị ọcha, na-ebelata ịdị ọcha SiC.

Site n'ịchịkwa ọdịnaya mgbakwunye (B 0.4 wt.%, C 1.8 wt.%) na sintering na 2150 ° C maka awa 0.5, a na-enweta ceramics SiC dị elu dị ọcha na ịdị ọcha nke 99.6 wt.% na njupụta nke 98.4%. Microstructure ahụ gosipụtara mkpụrụ osisi kọlụm (ụfọdụ gafere 450 µm n'ogologo), nwere obere pores na oke ọka na akụkụ graphite n'ime ọka. Ihe seramiiki ahụ gosipụtara ike mgbanwe nke 443 ± 27 MPa, modulu na-agbanwe nke 420 ± 1 GPa, yana ọnụọgụ mgbasawanye thermal nke 3.84 × 10⁻⁶ K⁻¹ n'ogo nke ụlọ okpomọkụ ruo 600 ° C, na-egosipụta arụmọrụ zuru oke.

Microstructure nke PSS-SiC: (A) SEM oyiyi mgbe polishing na NaOH etching; (BD) onyonyo BSD ka emechara ihicha na etching

III. Na-ekpo ọkụ ịpị Sintering

Igwe ọkụ na-ekpo ọkụ (HP) sintering bụ usoro densification nke n'otu oge na-etinye okpomọkụ na nrụgide uniaxial na ihe ntụ ntụ n'okpuru nnukwu okpomọkụ na ọnọdụ nrụgide dị elu. Nrụgide dị elu na-egbochi nhazi nke pore ma na-egbochi uto ọka, ebe okpomọkụ dị elu na-akwalite nchịkọta ọka na nhazi nke nnukwu ihe owuwu, n'ikpeazụ na-emepụta nnukwu njupụta, ceramics SiC dị ọcha. N'ihi ọdịdị ntụziaka nke ịpị, usoro a na-eme ka ọ na-ebute anisotropy ọka, na-emetụta ígwè ọrụ na iyi ihe.

Seramiki SiC dị ọcha na-esiri ike ịgbakọ na-enweghị mgbakwunye, chọrọ sintering ultrahigh-nrụgide. Nadeau et al. SiC siri ike kwadebere nke ọma na-enweghị mgbakwunye na 2500 ° C na 5000 MPa; Sun et al. nwetara β-SiC nnukwu ihe nwere ike Vickers ruru 41.5 GPa na 25 GPa na 1400°C. N'iji nrụgide 4 GPa, seramiki SiC nwere njupụta nke ihe dịka 98% na 99%, ike nke 35GPa, na modulus nke 450GPa ka edoziri na 1500 ° C na 1900 ° C, n'otu n'otu. Sintering micron-sized SiC ntụ ntụ na 5 GPa na 1500 ° C na-emepụta ceramik nwere ike nke 31.3 GPA na njupụta nke 98.4%.

Ọ bụ ezie na nsonaazụ ndị a gosipụtara na nrụgide ultrahigh nwere ike nweta densification na-enweghị mgbakwunye, mgbagwoju anya na ọnụ ahịa dị elu nke akụrụngwa achọrọ na-egbochi ngwa ụlọ ọrụ mmepụta ihe. Ya mere, na nkwadebe bara uru, a na-ejikarị ihe mgbakwunye trace ma ọ bụ ntụ ntụ mee ihe iji kwalite ike ịnya ụgbọ ala.

Site n'ịgbakwunye 4 wt.% phenolic resin dị ka mgbakwunye na sintering na 2350 ° C na 50 MPa, SiC ceramics nwere ọnụ ọgụgụ densification nke 92% na ịdị ọcha nke 99.998% nwetara. N'iji obere ihe mgbakwunye (boric acid na D-fructose) na sintering na 2050 ° C na 40 MPa, SiC dị ọcha dị elu nwere njupụta nke> 99.5% na ọdịnaya B fọdụrụnụ nke naanị 556 ppm kwadoro. Ihe oyiyi SEM gosiri na, ma e jiri ya tụnyere ihe nlele na-enweghị nrụgide, ihe ndị a na-ekpo ọkụ na-ekpo ọkụ nwere obere ọka, obere pores, na njupụta dị elu. Ike mgbanwe ahụ bụ 453.7 ± 44.9 MPa, na modul na-agbanwe agbanwe ruru 444.3 ± 1.1 GPa.

Site n'ịgbatị oge njide na 1900C, nha ọka rịrị elu site na 1.5 μm ruo 1.8 μm, na conductivity thermal mụbara site na 155 ruo 167 W·m⁻¹·K⁻¹, ebe na-akwalitekwa nguzogide corrosion plasma.

N'okpuru ọnọdụ nke 1850 ° C na 30 MPa, ịpị ọkụ na ngwa ngwa na-ekpo ọkụ nke granulated na anneal SiC ntụ ntụ na-emepụta ceramics β-SiC zuru oke na-enweghị ihe mgbakwunye ọ bụla, na njupụta nke 3.2 g / cm³ na okpomọkụ na-ekpo ọkụ 150-200 ° C dị ala karịa usoro omenala. Ihe seramiki ahụ gosipụtara isi ike nke 2729 GPA, mgbaji siri ike nke 5.25–5.30 MPa·m^1/2, yana ezigbo nguzogide na-akpụ akpụ (ọnụọgụ nke 9.9 × 10⁻¹⁰ s⁻¹ na 3.8 × 10⁻ ⁹ 1400°C/1450°C na 100MPa).

(A) Foto SEM nke elu a na-egbu maramara; (B) Foto SEM nke elu mgbawa; (C, D) onyonyo BSD nke elu a na-egbu maramara

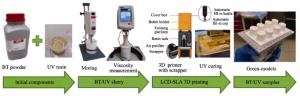

N'ime nchọpụta mbipụta 3D maka ceramics piezoelectric, ceramic slurry, dị ka isi ihe na-emetụta nhazi na ịrụ ọrụ, aghọwo isi ihe na-elekwasị anya n'ime ụlọ na mba ụwa. Ọmụmụ ihe dị ugbu a n'ozuzu na-egosi na paramita dị ka urughuru uzuzu, slurry viscosity, na ọdịnaya siri ike na-emetụta ọdịdị ọdịdị na piezoelectric nke ngwaahịa ikpeazụ.

Nnyocha achọpụtala na seramiiki slurries akwadoro site na iji micron-, submicron-, na nano-sized barium titanate powders na-egosipụta nnukwu ọdịiche na stereolithography (dịka ọmụmaatụ, LCD-SLA). Ka nha urughuru na-ebelata, viscosity slurry na-abawanye nke ọma, yana ntụ ntụ nwere nano na-emepụta slurries nwere viscosities ruru ijeri mPa·s. Slurries na micron-sized powders na-adịkarị mfe delamination na peeling n'oge obibi akwụkwọ, mgbe submicron na nano-sized powders na-egosipụta ọzọ kwụsiri ike akpụ omume. Mgbe ikpochasị okpomọkụ dị elu, ihe nlele seramiiki rụpụtara nwetara njupụta nke 5.44 g/cm³, ọnụọgụ piezoelectric (d₃₃) nke ihe dịka 200 pC/N, yana ihe ndị na-efunahụ dị ala, na-egosipụta njirimara nzaghachi electromechanical dị mma.

Na mgbakwunye, na usoro micro-stereolithography, ịhazigharị ọdịnaya siri ike nke ụdị slurries PZT (dịka ọmụmaatụ, 75 wt.%) na-ewepụta ozu ndị nwere njupụta nke 7.35 g/cm³, na-enweta piezoelectric mgbe niile ruru 600 pC/N n'okpuru oghere eletrik. Nnyocha na nkwụghachi nrụrụ micro-scale mere ka ọ dịkwuo mma n'ichepụta izi ezi, na-eme ka nzizi geometric dị ihe ruru 80%.

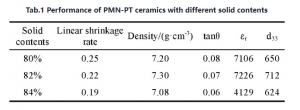

Nnyocha ọzọ na PMN-PT piezoelectric ceramics kpughere na ọdịnaya siri ike na-emetụta usoro seramiiki na akụrụngwa eletrik. Na 80 wt.% ọdịnaya siri ike, ihe ndị na-emepụta ihe na-apụta ngwa ngwa na ceramik; dị ka ihe siri ike na-abawanye ruo 82 wt.% na n'elu, ihe ndị na-emepụta ji nwayọọ nwayọọ na-apụ n'anya, usoro seramiiki wee dị ọcha, na-arụ ọrụ nke ọma. Na 82 wt.%, ceramics gosipụtara ihe ndị dị mma eletriki: piezoelectric na-adịgide adịgide nke 730 pC/N, ikike ikike nke 7226, na ọnwụ dielectric nke naanị 0.07.

Na nchịkọta, urughuru size, siri ike ọdịnaya, na rheological Njirimara nke seramiiki slurries bụghị nanị na-emetụta nkwụsi ike na izi ezi nke usoro obibi akwụkwọ kamakwa kpọmkwem na-ekpebi njupụta na piezoelectric nzaghachi nke sintered ozu, na-eme ka ha isi parameters maka ọbọ elu-arụmọrụ 3D-e biri ebi piezoelectric ceramics.

Isi usoro nke LCD-SLA 3D obibi nke BT/UV samples

Njirimara nke ceramik PMN-PT nwere ọdịnaya siri ike dị iche iche

IV. Spark Plasma Sintering

Spark plasma sintering (SPS) bụ nkà na ụzụ sintering dị elu nke na-eji nrụgide pulsed dị ugbu a na nke arụ ọrụ n'otu oge etinyere na ntụ ntụ iji nweta njupụta ngwa ngwa. N'ime usoro a, ugbu a na-ekpo ọkụ na ebu na ntụ ntụ, na-emepụta okpomọkụ Joule na plasma, na-eme ka ọ dị mma n'ime obere oge (na-emekarị n'ime nkeji 10). Igwe ọkụ na-ekpo ọkụ ngwa ngwa na-akwalite mgbasa nke elu, ebe mwepu ọkụ na-enyere aka wepụ gas na-ekpo ọkụ na oyi akwa oxide site na n'elu ntụ ntụ, na-eme ka arụmọrụ na-arụ ọrụ dịkwuo mma. Mmetụta eletrọnịkị na-ebute site na oghere elektrọnịkị na-akwalite mgbasa nke atọm.

E jiri ya tụnyere ịpị ọkụ ọdịnala, SPS na-arụ ọrụ kpo oku ozugbo, na-eme ka densification na okpomọkụ dị ala ma na-egbochi uto ọka nke ọma iji nweta ọmarịcha na otu microstructures. Ọmụmaatụ:

- Na-enweghị ihe mgbakwunye, na-eji ntụ ntụ SiC n'ala dị ka akụrụngwa, sintering na 2100 ° C na 70 MPa maka 30 nkeji na-emepụta samples na 98% ikwu njupụta.

- Sintering na 1700 ° C na 40 MPa maka nkeji 10 mepụtara cubic SiC na njupụta 98% na nha ọka nke naanị 30-50 nm.

- Iji 80 µm granular SiC ntụ ntụ na sintering na 1860 ° C na 50 MPa maka nkeji 5 rụpụtara arụmọrụ SiC ceramics dị elu na njupụta nke 98.5%, Vickers microhardness nke 28.5 GPa, ike mgbanwe nke 395 MPa, na mgbaji siri ike nke .5 MPa.

Nyocha microstructural gosiri na ka sintering okpomọkụ si na 1600 Celsius C ruo 1860 Celsius C, ihe porosity porosity ebelata nke ukwuu, na-abịaru nso njupụta zuru ezu na elu okpomọkụ.

Ihe microstructure nke ceramics SiC na-agbari na okpomọkụ dị iche iche: (A) 1600°C, (B) 1700°C, (C) 1790°C na (D) 1860°C

V. Mgbakwunye Mmepụta

Nrụpụta mgbakwunye (AM) egosipụtala ikike dị egwu n'ichepụta ihe seramiiki dị mgbagwoju anya n'ihi usoro owuwu ya site na oyi akwa. Maka ceramik SiC, e mepụtala ọtụtụ teknụzụ AM, gụnyere binder jetting (BJ), 3DP, selective laser sintering (SLS), ederede ink ozugbo (DIW), na stereolithography (SL, DLP). Otú ọ dị, 3DP na DIW nwere nkenke dị ala, ebe SLS na-ebute nrụgide okpomọkụ na mgbawa. N'ụzọ dị iche, BJ na SL na-enye uru dị ukwuu n'ịmepụta ceramics dị mgbagwoju anya dị elu, dị elu.

- Binder Jetting (BJ)

Nkà na ụzụ BJ na-agụnye ịgbanye ihe nkedo nke oyi akwa-site-layer na ntụ ntụ, na-esote debinding na sintering iji nweta ngwaahịa seramiiki ikpeazụ. Ijikọta BJ na kemịkalụ vapor infiltration (CVI), ịdị ọcha dị elu, ceramik SiC zuru oke nke kristal ka edoziri nke ọma. Usoro gụnyere:

① Ịmepụta ahụ SiC ceramic green na-eji BJ.

② Densifying site na CVI na 1000°C na 200 Torr.

③ Seramiiki SiC ikpeazụ nwere njupụta nke 2.95 g/cm³, conductivity thermal nke 37 W/m·K, yana ike mgbanwe nke 297 MPa.

Eserese eserese nke nrapado jet (BJ) obibi. (A) Ihe nlere kọmputa na-enyere aka (CAD), (B) eserese eserese nke ụkpụrụ BJ, (C) ibipụta SiC site na BJ, (D) densification nke SiC site na infiltration vapor (CVI)

- Stereolithography (SL)

SL bụ teknụzụ na-akpụ seramiiki na-agwọta UV nwere oke nkenke yana ikike imepụta ihe dị mgbagwoju anya. Usoro a na-eji seramiiki slurries photosensitive nwere nnukwu ọdịnaya siri ike yana viscosity dị ala iji mepụta ahụ seramiiki 3D site na fotopolymerization, na-esote debinding na ikpo ọkụ dị elu iji nweta ngwaahịa ikpeazụ.

N'iji 35 vol.% SiC slurry, a kwadebere ozu akwụkwọ ndụ akwụkwọ ndụ 3D dị elu n'okpuru 405 nm UV irradiation na n'ihu densified site polymer burnout na 800 ° C na PIP ọgwụgwọ. Nsonaazụ gosiri na nlele ndị ejiri 35 vol.% slurry akwadoro nwetara njupụta ikwu nke 84.8%, karịa 30% na 40% otu njikwa.

Site na iwebata SiO₂ lipophilic na phenolic epoxy resin (PEA) iji gbanwee slurry, arụ ọrụ photopolymerization ka emelitere nke ọma. Mgbe emechara na 1600 Celsius C maka 4 h, a na-enweta ntụgharị zuru oke na SiC, yana ọdịnaya oxygen ikpeazụ nke naanị 0.12%, na-eme ka otu nzọụkwụ dị elu nke ịdị ọcha dị elu, seramiiki SiC edoziri mgbagwoju anya na-enweghị tupu oxidation ma ọ bụ usoro ntinye ntinye.

Ihe atụ nke usoro obibi akwụkwọ na usoro nbipụta ya. Ọdịdị nke ihe nlele mgbe akpọnwụchara na (A) 25°C, pyrolysis na (B) 1000°C, na sintering na (C) 1600°C.

Site n'ichepụta photosensitive Si₃N₄ seramiiki slurries maka stereolithography 3D obibi na n'ọrụ debinding-presintering na elu okpomọkụ usoro ịka nká, Si₃N₄ ceramics na 93.3% theoretical njupụta, tensile ike nke 279.8 MP3.5 MP3 ike na flexural ike. e jikere. Nnyocha chọpụtara na n'okpuru ọnọdụ nke 45 vol.% ọdịnaya siri ike na oge ikpughe 10 s, enwere ike nweta ozu akwụkwọ ndụ akwụkwọ ndụ otu oyi akwa nwere nhazi ọkwa IT77. Usoro nbido dị ala nke nwere ọkụ ọkụ nke 0.1 Celsius C / min nyere aka mepụta ahụ ndụ ndụ ndụ na-enweghị mgbawa.

Sintering bụ isi nzọụkwụ na-emetụta arụmọrụ ikpeazụ na stereolithography. Nnyocha na-egosi na ịgbakwụnye ihe enyemaka na-eme ihe nwere ike imezi njupụta seramiiki na ihe eji arụ ọrụ nke ọma. N'iji CeO₂ dị ka ihe enyemaka na-enye aka na nkà na ụzụ sintering na-enyere aka n'ọhịa eletrik iji kwadebe ihe dị elu nke Si₃N₄ ceramics, CeO₂ na-ekewa n'ime oke ọka, na-akwalite mbanye ókèala ọka na densification. Ihe ceramik nke si na ya pụta gosipụtara ike nke Vickers nke HV10/10 (1347.9 ± 2.4) na mgbaji siri ike nke (6.57 ± 0.07) MPa·m¹/². Site na MgO-Y₂O₃ dị ka mgbakwunye, seramiiki microstructure homogeneity ka emelitere, na-eme ka arụmọrụ dịkwuo elu. Na ngụkọta doping larịị nke 8 wt.%, ike mgbanwe na thermal conductivity ruru 915.54 MPa na 59.58 W·m⁻¹·K⁻¹, n'otu n'otu.

VI. Mmechi

Na nchịkọta, seramiiki silicon carbide (SiC) dị ọcha, dị ka ihe seramiiki injinịa pụtara ìhè, egosipụtala atụmanya ngwa sara mbara na semiconductor, ikuku ikuku, na akụrụngwa nwere oke ọnọdụ. Akwụkwọ a tụlere n'usoro ụzọ ụzọ nkwadebe ise maka ceramics SiC dị ọcha - recrystallization sintering, sintering na-enweghị nrụgide, ịpị ọkụ, spark plasma sintering na mmepụta ihe - na mkparịta ụka zuru ezu na usoro njupụta ha, njikarịcha isi ihe, ịrụ ọrụ ihe, yana uru na njedebe dị iche iche.

O doro anya na usoro dị iche iche nke ọ bụla nwere njirimara pụrụ iche n'ihe gbasara imezu ịdị ọcha dị elu, njupụta dị elu, ihe mgbagwoju anya, na ike mmepụta ihe. Nkà na ụzụ mmepụta ihe mgbakwunye, karịsịa, egosila ikike siri ike n'ịmepụta ihe ndị dị mgbagwoju anya na nke ahaziri ahazi, na-enwe ọganihu na mpaghara subfields dị ka stereolithography na binder jetting, na-eme ka ọ bụrụ ntụziaka mmepe dị mkpa maka nkwadebe seramiiki SiC dị ọcha.

Nnyocha n'ọdịnihu banyere nkwadebe seramiiki SiC dị ọcha kwesịrị ịdị omimi karị, na-akwalite mgbanwe site na ụlọ nyocha-ọnụ ọgụgụ buru ibu, ngwa injinia a pụrụ ịdabere na ya nke ukwuu, si otú a na-enye nkwado ihe dị mkpa maka mmepụta ngwá ọrụ dị elu na teknụzụ ozi ọgbọ ọzọ.

XKH bụ ụlọ ọrụ teknụzụ dị elu na-ahụ maka nyocha na imepụta ihe seramiiki dị elu. A raara ya nye inye ndị ahịa ihe ngwọta ahaziri iche n'ụdị ceramics silicon carbide (SiC) dị ọcha. Ụlọ ọrụ ahụ nwere teknụzụ nkwadebe ihe dị elu yana ikike nhazi nke ọma. Azụmahịa ya gụnyere nyocha, mmepụta, nhazi nke ọma, na ọgwụgwọ elu nke ceramics SiC dị ọcha, na-ezute ihe siri ike nke semiconductor, ume ọhụrụ, ikuku ikuku na mpaghara ndị ọzọ maka akụrụngwa seramiiki dị elu. N'ịkwado usoro sintering tozuru okè na teknụzụ mmepụta ihe, anyị nwere ike inye ndị ahịa ọrụ nkwụsịtụ site na njikarịcha usoro ihe, nhazi usoro dị mgbagwoju anya na nhazi nke ọma, na-ahụ na ngwaahịa ndị ahụ nwere akụrụngwa akụrụngwa dị mma, nkwụsi ike ọkụ na nguzogide corrosion.

Oge nzipu: Jul-30-2025

-300x228.png)

1600°C、(B)1700°C、(C)1790°C-和(D)1860°C-300x223.png)

25°C-下干燥、(B)1000°C-下热解和(C)1600°C-下烧结后的外观-300x225.png)