Microjet laser technology akụrụngwa wafer ịcha SiC ihe nhazi

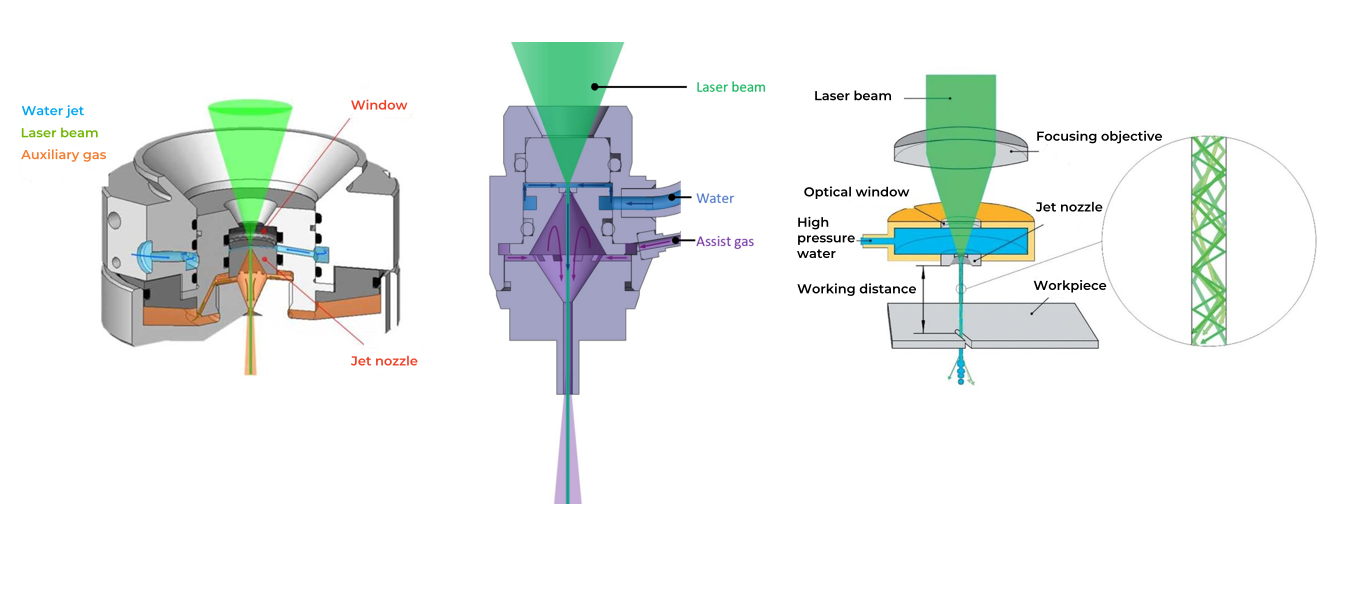

Ụkpụrụ ọrụ:

1. Laser njikọ: pulsed laser (UV / green / infrared) na-elekwasị anya n'ime mmiri mmiri jet na-etolite ike ike nnyefe ọwa.

2. Ntuzi mmiri: jet dị elu (ọnụọgụ 50-200m / s) na-eme ka ebe nhazi ahụ dị jụụ ma wepụ ihe mkpofu iji zere ikpo ọkụ na mmetọ.

3. Mwepụ ihe: Ike laser na-akpata mmetụta cavitation na mmiri mmiri iji nweta nhazi oyi nke ihe (mpaghara emetụta okpomọkụ <1μm).

4. Njikwa na-agbanwe agbanwe: nhazi oge nke laser parameters (ike, ugboro) na nrụgide jet iji gboo mkpa nke ihe dị iche iche na nhazi.

Igodo akara:

1. Ike Laser: 10-500W (nwere ike idozi)

2. Dayameta Jet: 50-300μm

3.Machining ziri ezi: ± 0.5μm (ịcha), omimi ka obosara ruru 10: 1 (ịkụ mmiri)

Uru teknụzụ:

(1) Ihe fọrọ nke nta ka ọ bụrụ efu okpomọkụ mmebi

- Mmiri mmiri mmiri jụrụ oyi na-achịkwa mpaghara okpomọkụ emetụtara (HAZ) ruo ** <1μm**, na-ezere micro-cracks kpatara nhazi laser omenala (HAZ na-abụkarị> 10μm).

(2) Mwepụta nke ọma dị oke elu

- Ịcha / igwu ihe ziri ezi ruo ** ± 0.5μm **, ihu roughness Ra <0.2μm, belata mkpa maka polishing na-esote.

- Na-akwado nhazi usoro nhazi 3D dị mgbagwoju anya (dịka oghere conical, oghere nwere ụdị).

(3) ndakọrịta ihe sara mbara

- Ihe siri ike na mgbawa: SiC, sapphire, iko, ceramics (ụzọ ọdịnala dị mfe imebi).

- Ihe na-emetụ ọkụ: polymers, anụ ahụ dị ndụ (enweghị ihe ize ndụ nke denaturation thermal).

(4) Nchekwa gburugburu ebe obibi na arụmọrụ

- Enweghị mmetọ uzuzu, enwere ike ịmegharị mmiri mmiri ma kpochaa ya.

- 30% -50% abawanye na nhazi ọsọ (vs. machining).

(5) njikwa ọgụgụ isi

- Ntinye ihu igwe jikọtara ọnụ na njikarịcha paramita AI, ọkpụrụkpụ ihe na-agbanwe agbanwe na ntụpọ.

Nkọwapụta nka na ụzụ:

| Olu Countertop | 300*300*150 | 400*400*200 |

| Linear axis XY | Moto Linear. Moto Linear | Moto Linear. Moto Linear |

| Linear axis Z | 150 | 200 |

| Ndokwa ziri ezi μm | +/-5 | +/-5 |

| Ndokwa ugboro ugboro μm | +/-2 | +/-2 |

| Ngwa ngwa G | 1 | 0.29 |

| Njikwa ọnụọgụgụ | 3 axis / 3+1 axis / 3+2 axis | 3 axis / 3+1 axis / 3+2 axis |

| Ụdị njikwa ọnụọgụgụ | DPSS Nd:YAG | DPSS Nd:YAG |

| Ogologo ogologo nm | 532/1064 | 532/1064 |

| Enyere ike W | 50/100/200 | 50/100/200 |

| Ụgbọ mmiri | 40-100 | 40-100 |

| Ogwe nrụgide nozzle | 50-100 | 50-600 |

| Akụkụ (ngwaọrụ igwe) (obosara * ogologo * elu) mm | 1445*1944*2260 | 1700*1500*2120 |

| Nha (kabinet njikwa) (W * L * H) | 700*2500*1600 | 700*2500*1600 |

| Arọ (ngwaọrụ) T | 2.5 | 3 |

| Arọ (kabinet njikwa) KG | 800 | 800 |

| Ike nhazi | Ịdị njọ nke elu Ra≤1.6um Ọsọ imeghe ≥1.25mm/s Mbelata okirikiri ≥6mm/s Linear ọnwụ ọsọ ≥50mm/s | Ihu igwe dị n'elu Ra≤1.2um Ọsọ imeghe ≥1.25mm/s Mbelata okirikiri ≥6mm/s Linear ọnwụ ọsọ ≥50mm/s |

| N'ihi na gallium nitride crystal, ultra-wide band gap semiconductor ihe (diamond/Gallium oxide), aerospace pụrụ iche ihe, LTCC carbon seramiiki mkpụrụ, photovoltaic, scintillator crystal na ihe ndị ọzọ nhazi. Mara: Ike nhazi dịgasị iche dabere na njirimara ihe

| ||

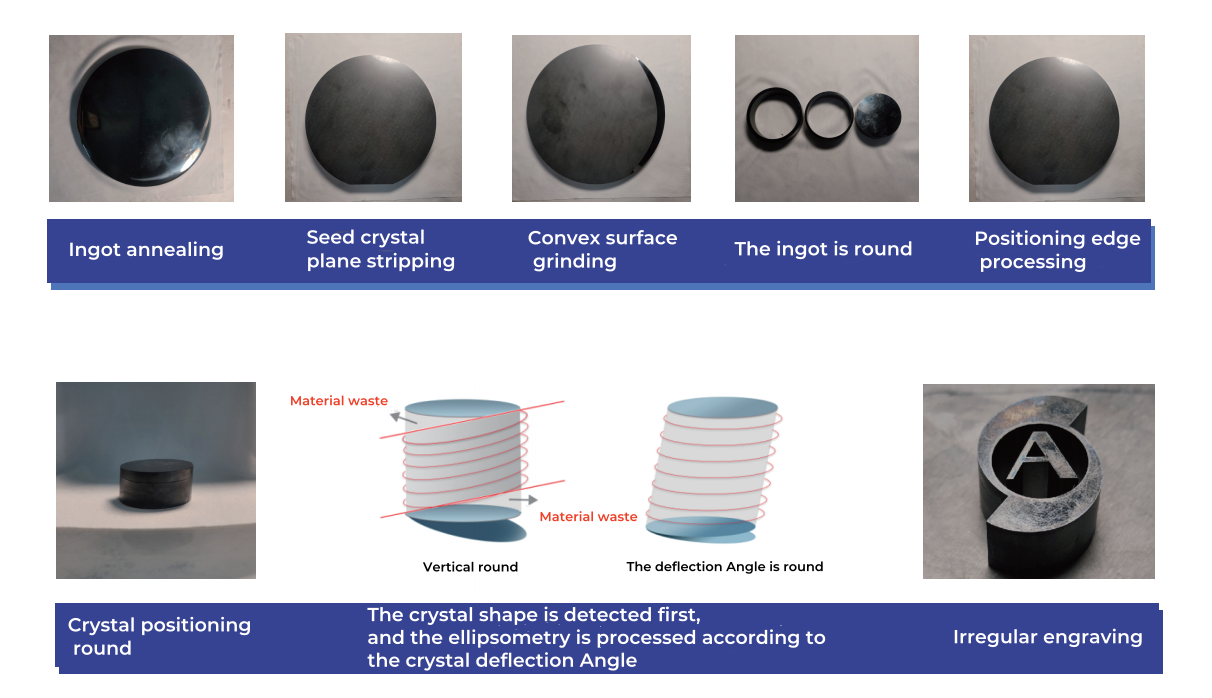

Usoro nhazi:

Ọrụ XKH:

XKH na-enye nkwado zuru oke nke ọrụ okirikiri ndụ zuru oke maka akụrụngwa teknụzụ laser microjet, site na mmalite usoro mmepe na nhọpụta akụrụngwa, na njikọta usoro ahaziri n'etiti etiti oge (gụnyere matching pụrụ iche nke isi iyi laser, sistemu jet na modul akpaaka), na-arụ ọrụ na ọzụzụ mmezi na njikarịcha usoro na-aga n'ihu, usoro ahụ dum nwere nkwado otu ọkachamara ọkachamara; Dabere na afọ 20 nke ahụmịhe nrụzi nke ọma, anyị nwere ike ịnye azịza otu nkwụsị gụnyere nkwenye akụrụngwa, mmeghe mmepụta oke na nzaghachi ngwa ngwa ahịa (awa 24 nke nkwado teknụzụ + ihe nchekwa ihe nchekwa) maka ụlọ ọrụ dị iche iche dị ka semiconductor na ahụike, ma kwe nkwa ọnwa 12 ogologo akwụkwọ ikike na mmezi ndụ yana ọrụ nkwalite. Gbaa mbọ hụ na akụrụngwa ndị ahịa na-ejigide arụmọrụ na nkwụsi ike nke ụlọ ọrụ na-eduga mgbe niile.

Eserese zuru ezu