Infrared Picosecond Dual-Platform Laser Akụrụngwa maka Nhazi Glass/Quartz/Sapphire

Isi oke

| Ụdị Laser | Infrared Picosecond |

| Nha Platform | 700×1200 (mm) |

| 900×1400 (mm) | |

| Ịcha Ọkpụrụkpụ | 0.03-80 (mm) |

| Ịcha ọsọ | 0-1000 (mm/s) |

| Ịcha Edge Breakage | <0.01 (mm) |

| Mara: Enwere ike ịhazi nha ikpo okwu. | |

Atụmatụ igodo

1.Ultrafast Laser Technology:

Ọkpụkpụ mkpirisi ọkwa Picosecond (10⁻¹²) jikọtara ya na teknụzụ imegharị MOPA na-enweta njupụta ike kacha elu> 10¹² W/cm².

Ogologo eriri infrared (1064nm) na-abanye n'ime ihe ndị na-emepụta ihe site na ntinye na-adịghị na ntanetị, na-egbochi ablation elu.

Sistemụ anya anya nke ọtụtụ ihe na-emepụta ebe nhazi anọ nwere onwe ha n'otu oge.

Sistemụ mmekọrịta mmekọrịta 2.Dual-Station:

· Granite-base dual moto linear (nhazi nke ọma: ± 1μm).

Oge ngbanwe ọdụ ụgbọ <0.8s, na-eme ka arụ ọrụ "nhazi-loading/ebutu" yiri ya.

· Njikwa okpomọkụ nke onwe (23 ± 0.5 ° C) kwa ọdụ na-eme ka nkwụsi ike nke igwe ogologo oge.

3.Intelligent Usoro njikwa:

Ebe nchekwa data agbakwunyere (200+ iko iko) maka ndakọrịta oke akpaka.

Nleba anya plasma na-eme n'ezie na-agbanwe ike laser (mkpebi mmezi: 0.1mJ).

· Nchekwa ákwà mgbochi ikuku na-ebelata obere mgbawa ihu (<3μm).

N'ime ngwa ngwa nke metụtara 0.5mm-oke sapphire wafer dicing, usoro ahụ na-enweta mbelata ọsọ nke 300mm/s na akụkụ chipping <10μm, na-anọchi anya nkwalite arụmọrụ 5x karịa usoro ọdịnala.

Nhazi Uru

1.Integrated dual-station ọnwụ na nkewa usoro maka mgbanwe ọrụ;

2.High-speed machining nke mgbagwoju geometric na-eme ka usoro ngbanwe arụmọrụ;

3.Taper-free mbepụ ọnụ na ntakiri chipping (<50μm) na onye ọrụ-nchekwa njikwa;

4.Seamless mgbanwe n'etiti ngwaahịa nkọwa na kensinammuo ọrụ;

5.Low na-akwụ ụgwọ ọrụ, ọnụ ọgụgụ dị elu nke mkpụrụ osisi, usoro na-eri nri na-enweghị mmetọ;

6.Zero ọgbọ nke slag, ihe mkpofu mmiri ma ọ bụ mmiri na-ekpofu mmiri na-ekwe nkwa n'elu iguzosi ike n'ezi ihe;

Ngosipụta ihe atụ

Ngwa a na-ahụkarị

1. Consumer Electronics Manufacturing:

· Nkenke contour ọnwụ nke smartphone 3D mkpuchi iko (R-n'akuku ziri ezi: ± 0.01mm).

· Mkpọpu oghere na oghere sapphire (oghere kacha nta: Ø0.3mm).

· Emecha mpaghara mpaghara na-ebufe enyo anya maka igwefoto n'okpuru ngosipụta.

2.Mpụta akụrụngwa ngwa anya:

Machining Microstructure maka oghere oghere AR/VR (nha njirimara ≥20μm).

· Mbelata akụkụ nke quartz prisms maka ndị na-ahụ maka laser ( nnabata angular: ± 15 ").

Ịkpụzi profaịlụ nke nzacha infrared (ịcha taper <0.5°).

3.Semiconductor nkwakọ ngwaahịa:

· Glass site-via (TGV) nhazi na wafer larịị (akụkụ ruru 1:10).

· Microchannel etching na iko iko maka microfluidic ibe (Ra <0.1μm).

· Mbelata ngbanwe ugboro ugboro maka ndị na-emegharị quartz MEMS.

Maka imepụta windo ngwa anya LiDAR ụgbọ ala, sistemụ ahụ na-enyere aka ịkpụ iko nke iko quartz 2mm nwere oke nke 89.5 ± 0.3 Celsius, na-ezute ihe nyocha chọrọ ịma ọkwa ụgbọ ala.

Ngwa nhazi

Emebere ya nke ọma maka igbutu ihe ndị siri ike nke ọma gụnyere:

1.Standard iko & anya anya (BK7, fused silica);

2. kristal quartz & sapphire substrates;

3. Igwe ọkụ ọkụ & ihe nzacha anya

4. Mirror substrates

Nwere ike nke ịkpụcha akụkụ na nkenke nke ọma n'ime oghere (opekempe Ø0.3mm)

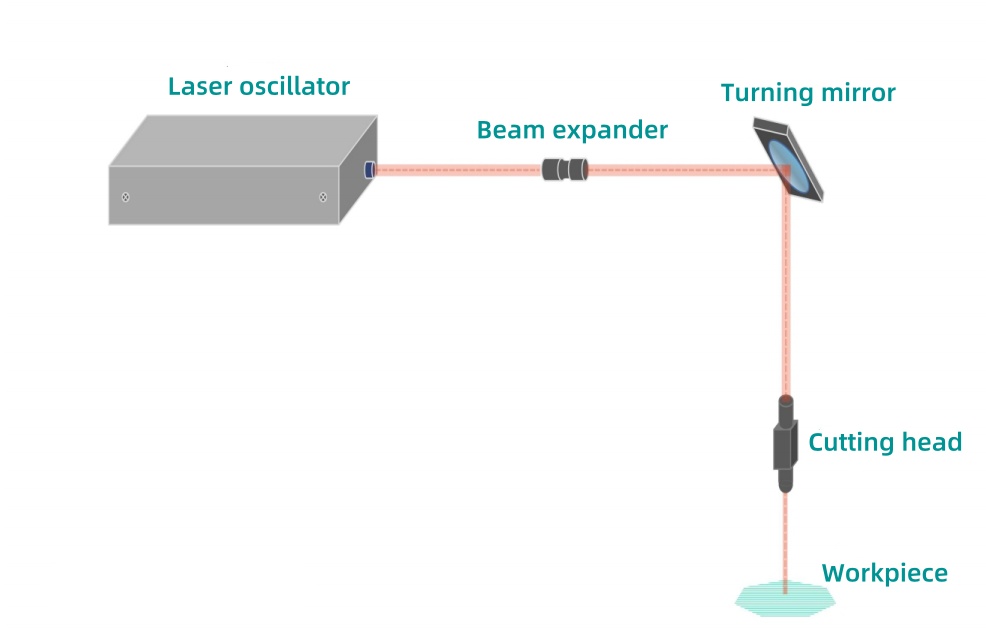

Ụkpụrụ Ịcha Laser

Laser na-emepụta ultrashort pulses nwere ike dị oke elu nke na-emekọrịta ihe na-arụ ọrụ n'ime oge femtosecond-to-picosecond. N'oge a na-agbasa site na ihe ahụ, osisi ahụ na-akpaghasị usoro nrụgide ya iji mepụta oghere filamentation micron-scale. Oghere oghere emeziri nke ọma na-ebute obere mgbawa a na-achịkwa, nke jikọtara ya na teknụzụ nkesa iji nweta nkewa nkenke.

Uru Ịcha Laser

1.High automation integration (jikọta ịkpụ / cleaving ọrụ) na obere ike oriri na simplified ọrụ;

2.Non-contact nhazi na-enyere ike pụrụ iche na-apụghị iru site na usoro omenala;

3.Consumable-free ọrụ na-ebelata ọnụ ahịa na-agba ọsọ ma na-akwalite nkwado gburugburu ebe obibi;

4.Superior ziri ezi na efu taper angle na mkpochapụ nke abụọ workpiece mebiri;

XKH na-enye ọrụ nhazi zuru oke maka sistemu ịcha laser anyị, gụnyere nhazi n'elu ikpo okwu ahaziri ahazi, mmepe nke usoro pụrụ iche, yana ngwa-ngwa ngwa iji gboo mkpa mmepụta pụrụ iche n'ofe ụlọ ọrụ dị iche iche.