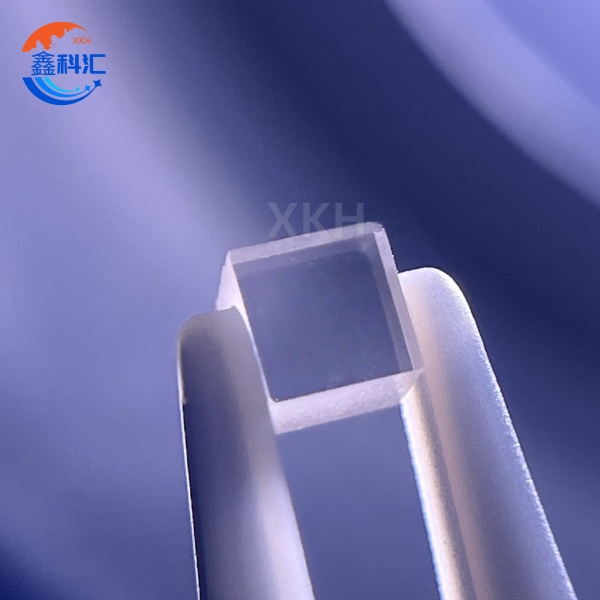

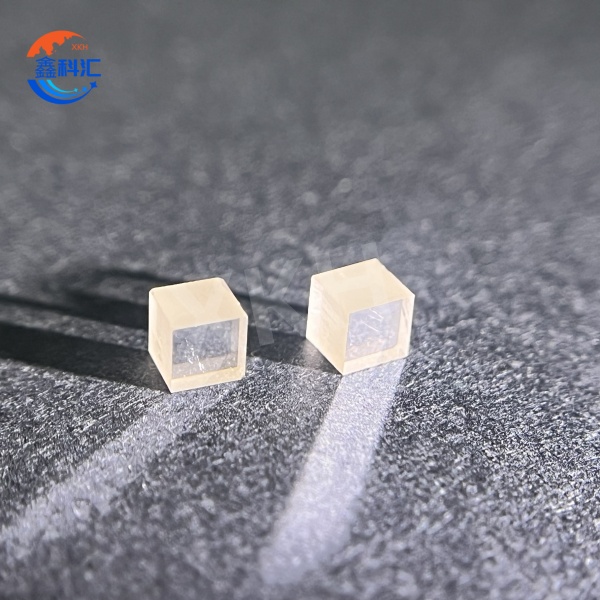

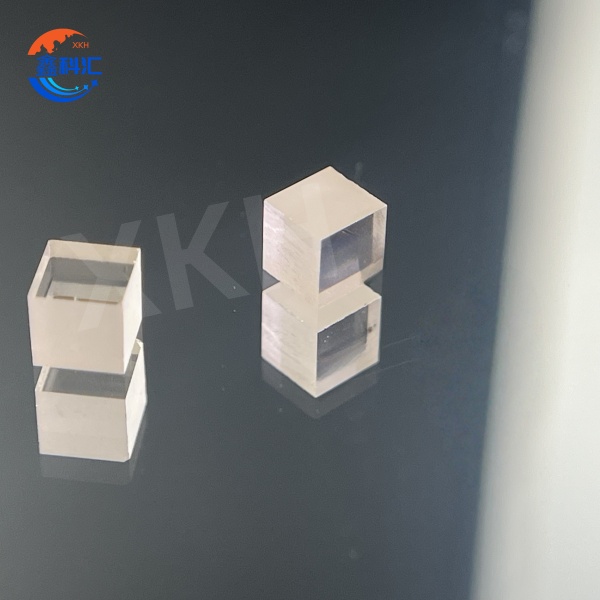

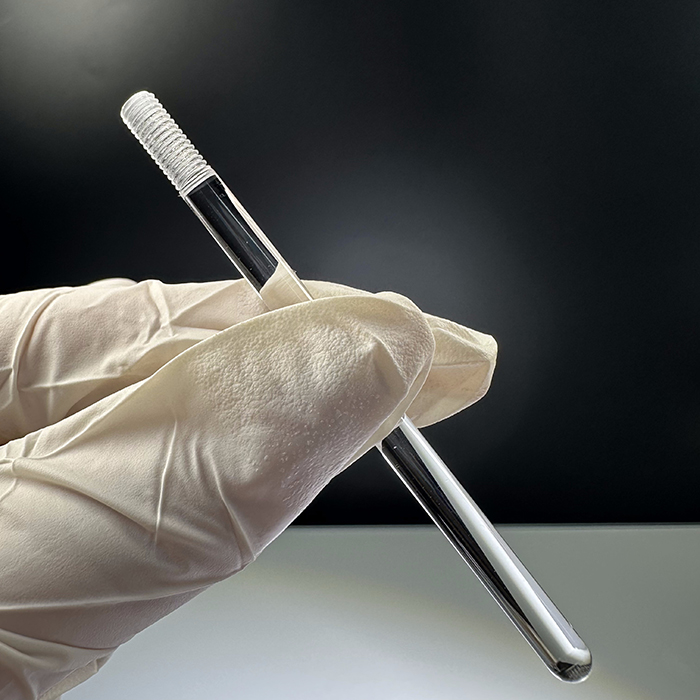

Ọdịnaya dị elu SiC Optical Lens Cubic 4H-semi 6SP nha ahaziri

Njirimara nke oghere anya anya SiC

1. Ihe kacha elu

Mgbanwe gburugburu ebe obibi dị oke egwu: Na-eguzogide okpomọkụ> 1500 ° C, acid / alkali corrosion siri ike, na ọkụ ọkụ dị elu, dị mma maka ụgbọ elu na ngwá ọrụ nuklia.

Ike Mechanical Pụrụ Iche: Ike siri ike dị nso (Mohs 9.5), ike mgbanwe> 400 MPa, yana nguzogide mmetụta karịrị enyo anya anya.

Thermal Stability: Thermal conductivity 100 × dị elu karịa silica fused, yana CTE naanị 1/10 nke iko nkịtị, na-eme ka nkwụsi ike n'okpuru ịgba ígwè ọkụ ọkụ ngwa ngwa.

2. Ngwa anya arụmọrụ Uru

Mgbasa mgbasa ozi sara mbara (0.2-6 μm); mkpuchi pụrụ iche nwere ike ịkwalite mbufe na> 95% n'ime ụgbụ a kapịrị ọnụ (dịka, 3-5 μm mid-IR).

Mfu mgbasasị dị ala (<0.5%/cm), imecha elu ruo 10/5 ọkọlọtọ-egwupụta, yana flatness elu λ/10@633 nm.

Ọnụ ụzọ mmebi nke laser dị elu (LIDT)> 15 J/cm² (1064 nm, 10 ns pulses), dabara maka sistemụ na-elekwasị anya laser dị elu.

3. Ikike Machining nkenke

Na-akwado elu mgbagwoju anya (aspheric, freeform) na ụdị ziri ezi <100 nm PV na centration <1 arcmin.

Nwere ike imepụta lensị SiC buru ibu (dayameta> 500 mm) maka teliskop nke mbara igwe na ngwa anya oghere.

Ngwa izizi nke oghere anya SiC

1. Space Optics & Nchekwa

Igwe anya anya anya satịlaịtị na-ahụ anya na oghere teliskop optics, na-eme ka arịa dị fechaa SiC (njupụta 3.21 g/cm³) yana nguzogide radieshon.

Window ngwa anya onye na-achọ ogbunigwe, kpo oku ikuku ikuku (>1000°C) n'oge ụgbọ elu hypersonic.

2. Elu-ike Laser Systems

Lensị anya maka ụlọ ọrụ mmepụta ihe na-egbutu / ịgbado ọkụ laser, na-akwado ogologo ikpughe na lasers kW-klas na-aga n'ihu.

Ihe na-akpụpụta ihe na-emepụta ihe na sistemụ inertial confinement fusion (ICF), na-ahụ maka nnyefe laser dị elu.

3. Semiconductor & Nrụpụta nkenke

Igwe enyo SiC maka EUV lithography optics, nwere nrụrụ ọkụ <1 nm n'okpuru 10 kW/m² okpomọkụ.

Igwe eletrọnịkị maka ngwaọrụ nyocha e-beam, na-eji ihe omume SiC maka njikwa okpomọkụ na-arụ ọrụ.

4. Nyocha ụlọ ọrụ & ike

lenses Endoscope maka ọkụ ọkụ dị elu (1500 Celsius C na-aga n'ihu).

Infrared optical components maka mmanụ na-egbu osisi nke ọma, na-eguzogide nrụgide ala (> 100 MPa) na mgbasa ozi na-emebi emebi.

Uru asọmpi isi

1. Comprehensive Performance Leadership

lenses SiC karịrị ngwa ngwa anya ọdịnala (silica fused, ZnSe) na nkwụsi ike nke thermal/mechanical/chemical, na ihe “ịdị elu conductivity + obere mgbasawanye” ha na-edozi ihe ịma aka nrụrụ ọkụ na nnukwu optics.

2. Nrụmọrụ ọnụ ahịa ndụ ndụ

Ọ bụ ezie na ọnụ ahịa mbụ dị elu, ndụ ogologo ọrụ anya lenses SiC (5-10× iko nkịtị) yana ọrụ enweghị mmezi na-ebelata oke ọnụ ahịa nke nwe (TCO).

3. Imepụta nnwere onwe

Mmeghachi omume-njikọ ma ọ bụ CVD usoro na-eme ka SiC ngwa anya Ọdịdị (cores honeycomb), na-enweta oke isiike-na-arọ na-enweghị atụ.

Ike ọrụ XKH

1. Ọrụ nrụpụta omenala

Ngwọta ngwụcha na njedebe site na nhazi ngwa anya (Zemax/Code V simulation) ruo na nnyefe ikpeazụ, na-akwado ebe a na-eme ihe n'ụdị parabolic nke aspheric/off-axis.

Ihe mkpuchi pụrụ iche: mgbochi ntụgharị (AR), carbon dị ka diamond (LIDT> 50 J / cm²), ITO na-eduzi, wdg.

2. Usoro mmesi obi ike

Akụrụngwa gbasara usoro ọmụmụ gụnyere 4D interferometers na ndị na-ahụ maka ọkụ na-acha ọcha na-agba mbọ hụ na λ/20 ziri ezi.

Ọkwa QC: XRD crystallographic nghazi nyocha maka oghere SiC ọ bụla.

3. Ọrụ agbakwunyere uru

Thermo-structural coupling analysis (ANSYS simulation) maka amụma arụmọrụ.

Nrụpụta nrụnye oghere oghere SiC jikọtara ọnụ.

Mmechi

lenses SiC na-akọwapụta oke arụmọrụ nke sistemu ngwa anya dị elu site na ihe onwunwe ha na-enweghị atụ. Ike anyị jikọtara kwụ ọtọ na njikọ ihe SiC, nrụpụta nkenke, na nnwale na-ebuga azịza ngwa anya mgbanwe maka ikuku ikuku na ngalaba nrụpụta dị elu. Site n'ọganihu na uto kristal SiC, ihe ga-eme n'ọdịnihu ga-elekwasị anya na oghere ndị buru ibu (> 1m) na geometry elu dị mgbagwoju anya (ụdị freeform).

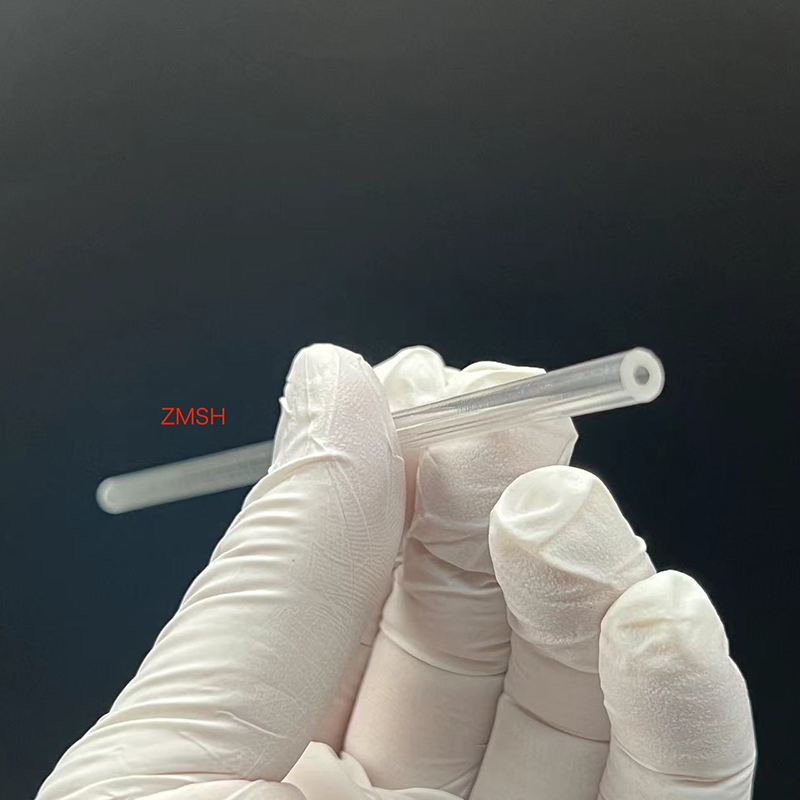

Dị ka onye na-emepụta ihe na-emepụta ngwa anya dị elu, XKH ọkachamara na ihe ndị dị elu gụnyere sapphire, silicon carbide (SiC), na silicon wafers, na-enye ngwọta njedebe na njedebe site na nhazi ngwa ngwa ruo na njedebe nkenke. Ọkachamara anyị gụnyere:

1. Omenala Nrụpụta: Nrụpụta ziri ezi nke geometries dị mgbagwoju anya (aspheric, freeform) na nnabata ruo ± 0.001mm

2. Ihe dị iche iche nke ihe: Sapphire na-arụ ọrụ (windo UV-IR), SiC (ike optics), na silicon (IR / micro-optics)

3. Ọrụ agbakwunyere uru:

Ihe mkpuchi mgbochi na-atụgharị uche / na-adịgide adịgide (UV-FIR)

Nkwenye ịdị mma na-akwado Metrology (λ/20 flatness)

Mkpọkọta ọnụ ụlọ dị ọcha maka ngwa nwere mmetụta mmetọ

Na-eje ozi ikuku, semiconductor, na ụlọ ọrụ laser, anyị na-ejikọta nkà mmụta sayensị ihe onwunwe na nrụpụta dị elu iji wepụta ngwa anya na-eguzogide oke gburugburu ebe na-eme ka arụmọrụ anya dị elu.