Akụrụngwa polishing otu akụkụ dị oke nkenke

Vidiyo nke ngwa nchacha n'akụkụ otu

Ewebata ngwa nkpuchi otu akụkụ

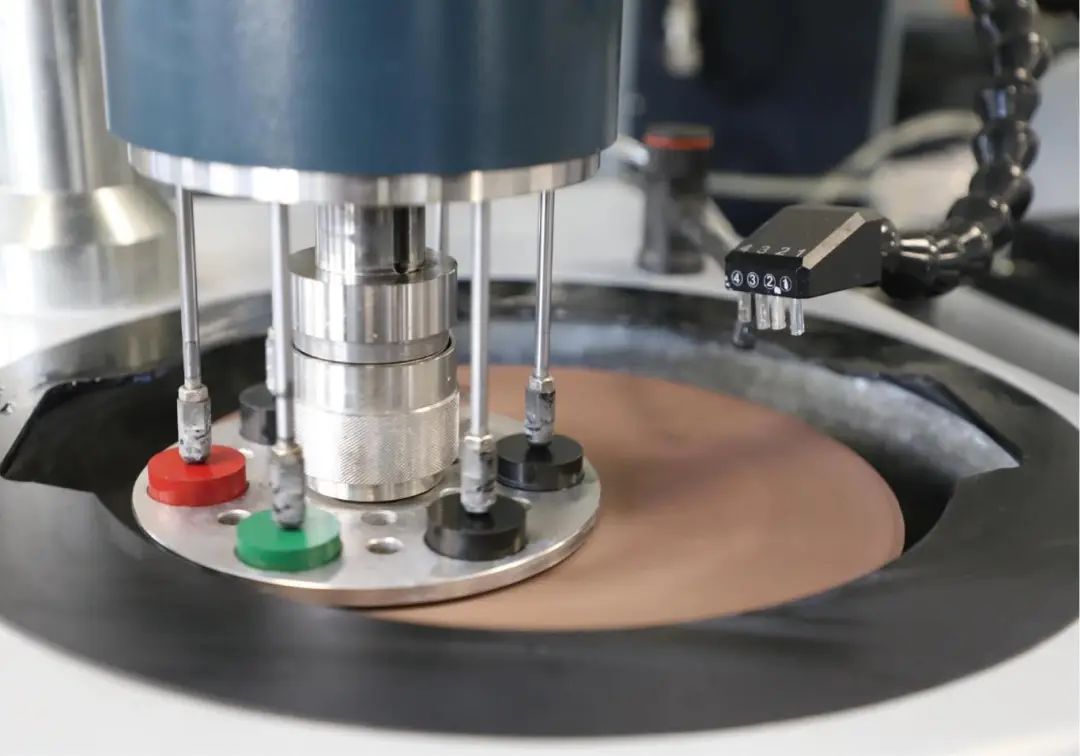

Igwe na-egbuke egbuke nke otu akụkụ bụ ngwá ọrụ pụrụ iche nke e mere maka imecha nke ọma nke ihe ndị siri ike na ndị na-agbaji agbaji. Site na mmepe ngwa ngwa nke ụlọ ọrụ semiconductor, optoelectronics, ngwa anya, na ngwa ihe dị elu, ọchịchọ maka ngwa polishing dị elu na nke dị elu na-adịwanye ngwa ngwa. Igwe na-egbuke egbuke nke otu akụkụ na-eji mmegharị nke dị n'etiti diski na-egbuke egbuke na efere seramiiki na-emepụta nrụgide otu n'elu ebe a na-arụ ọrụ, na-eme ka atụmatụ dị mma na njedebe dị ka mirror.

N'adịghị ka igwe nchacha nke akụkụ abụọ nke ọdịnala, igwe polishing nke otu akụkụ na-enye mgbanwe dị ukwuu n'ijikwa nha dị iche iche na ọkpụrụkpụ nke wafer ma ọ bụ ihe dị iche iche. Nke a na-eme ka ọ dị mma maka nhazi ihe dịka silicon wafers, silicon carbide, sapphire, gallium arsenide, germanium flakes, lithium niobate, lithium tantalate, na enyo anya. Nkenke nke ejiri ụdị ngwa a nweta na-eme ka a mata na ihe ndị a haziri ahazi na-emezu ihe achọrọ siri ike nke microelectronics, substrates LED, na ngwa anya dị elu.

Uru nke ngwa nkpuchi otu akụkụ

Nkà ihe ọmụma imewe nke igwe na-egbuke egbuke nke otu akụkụ na-emesi ike nkwụsi ike, nkenke, na arụmọrụ. A na-ejikarị ihe nkedo na ígwè arụrụ arụ arụ arụ ọrụ, nke na-enye nkwụsi ike n'arụ ọrụ ma na-ebelata mkpọtụ n'oge arụ ọrụ. A na-anakwere akụrụngwa mba ụwa dị elu maka sistemu dị oke egwu dị ka mbanye ntụgharị, nnyefe ike, na sistemụ njikwa, na-ahụ na arụmọrụ a pụrụ ịdabere na ya na ogologo ndụ ọrụ.

Ihe ọzọ bụ isi uru bụ na ya humanized ọrụ interface. Igwe nchacha nke otu akụkụ nke ọgbara ọhụrụ nwere ogwe njikwa nwere ọgụgụ isi, na-enye ndị na-arụ ọrụ ohere ịhazigharị usoro ngwa ngwa dị ka polishing ọsọ, nrụgide, na ọnụego ntụgharị. Nke a na-eme ka ọnọdụ nhazi nke nwere ike imepụtaghachi nke ukwuu, nke dị mkpa maka ụlọ ọrụ ebe nkwekọ dị oke mkpa.

Site n'echiche nke ntụgharị usoro, akụrụngwa nwere ike ịnabata ụdị nha nha nha, nke sitere na 50mm ruo 200mm ma ọ bụ karịa, dabere na ụdị. Ọnụego ntụgharị nke diski na-egbuke egbuke na-adaba n'etiti 50 ruo 80 rpm, ebe ogo ike dị iche site na 11kW ruo n'elu 45kW. Site na ụdị nhazi dị iche iche dị otú ahụ, ndị ọrụ nwere ike ịhọrọ ụdị nke kachasị mma maka mmepụta ihe ha chọrọ, ma ọ bụ maka ụlọ nyocha nyocha ma ọ bụ maka mmepụta ụlọ ọrụ buru ibu.

Ọzọkwa, ụdị dị elu nwere ọtụtụ isi na-egbuke egbuke, nke sistemụ njikwa eletrọnịkị servo mekọrịtara. Nke a na-eme ka isi polishing niile na-aga n'ihu na-agba ọsọ mgbe a na-arụ ọrụ, si otú a na-emeziwanye ogo nhazi na mkpụrụ. Tụkwasị na nke ahụ, usoro nhazi oyi na okpomọkụ na-ejikọta n'ime igwe na-ekwe nkwa nkwụsi ike nke okpomọkụ, nke bụ ihe dị mkpa mgbe ị na-emeso ihe ndị na-ekpo ọkụ ọkụ.

Igwe na-egbuke egbuke nke otu akụkụ na-anọchite anya ihe dị oke mkpa nke mmepụta ihe na oge a nke nkà na ụzụ dị elu. Ya Nchikota siri ike n'ibu imewe, ọgụgụ isi akara, multi-ihe ndakọrịta, na elu elu imecha arụmọrụ na-eme ka ọ bụrụ ihe dị oké mkpa ngwá ọrụ maka ụlọ ọrụ na nnyocha institutes na-achọ elu-n'ezi n'elu nkwadebe nke elu ihe.

Njirimara ngwaahịa nke Ngwa polishing otu akụkụ

-

Nkwụsi ike dị elu: A na-atụba ahụ igwe ahụ ma mebie ya iji hụ na nkwụsi ike nhazi na nkwụsi ike arụmọrụ dị mma.

-

Ngwa nkenke: Mpempe ọkwa ọkwa mba ụwa, moto, na ngalaba njikwa eletrọnịkị na-ekwe nkwa ogologo ndụ na arụmọrụ a pụrụ ịdabere na ya.

-

Ụdị mgbanwe: Dị na multiple usoro (305, 36D, 50D, 59D, na X62 S59D-S) izute iche iche mmepụta chọrọ.

-

Interface Humanized: Ogwe ọrụ dị mfe iji nwere ntọala dijitalụ maka polishing parameters, na-eme mgbanwe nhazi ngwa ngwa.

-

Ịjụ oyi nke ọma: Sistemụ ejikọtara mmiri na-ekpo ọkụ na ihe mmetụta okpomọkụ nke ọma iji nọgide na-enwe ọnọdụ polishing kwụsiri ike.

-

Mmekọrịta ọtụtụ isi: Njikwa eletrọnịkị nke Servo na-emekọrịta ọsọ nke ọtụtụ isi polishing maka nsonaazụ na-agbanwe agbanwe.

Nkọwa nka na ụzụ nke akụrụngwa polishing otu akụkụ

| Otu | Ihe | Usoro 305 | Usoro 36D | Usoro 50D | Usoro 59D |

|---|---|---|---|---|---|

| Diski na-ekpochapụ | Dayameta | 820 mm | 914 mm | 1282 mm | 1504 mm |

| Efere seramiiki | Dayameta | 305 mm | 360 mm | 485 mm | 576 mm |

| Machining kacha mma | Size workpiece | 50-100 mm | 50-150 mm | 150-200 mm | 200 mm |

| Ike | Isi moto | 11 kW | 11 kW | 18.5 kW | 30 kW |

| Ọnụọgụgụ ntụgharị | Diski na-ekpochapụ | 80 rpm | 65 rpm | 65 rpm | 50 rpm |

| Akụkụ (L×W×H) | - | 1920 × 1125 × 1680 mm | 1360×1330×2799 mm | 2334 × 1780 × 2759 mm | 1900 × 1900 × 2700 mm |

| Ibu igwe | - | 2000 n'arọ | 3500 n'arọ | 7500 n'arọ | 11826 n'arọ |

| Ihe | Oke | Ihe onwunwe |

|---|---|---|

| Dayameta nke Isi Polishing Disc | Φ1504 × 40 mm | SUS410 |

| Dayameta nke Polishing Disc (Isi) | Φ576 × 20 mm | SUS316 |

| Ọsọ kacha nke diski isi Polishing | 60 rpm | - |

| Ọsọ kacha nke isi ịtụfe elu | 60 rpm | - |

| Ọnụọgụ ndị isi polishing | 4 | - |

| Akụkụ (L×W×H) | 2350 × 2250 × 3050 mm | - |

| Akụrụngwa arọ | 12 t | - |

| Oke mgbali elu | 50-500 ± n'arọ | - |

| Mgbakọta ike nke igwe dum | 45 kW | - |

| Ikike ibu (kwa isi) | 8 h/φ 150 mm (6 ") ma ọ bụ 5 h/φ 200 mm (8") | - |

Ngwa ngwa nke ngwa nkpuchi otu akụkụ

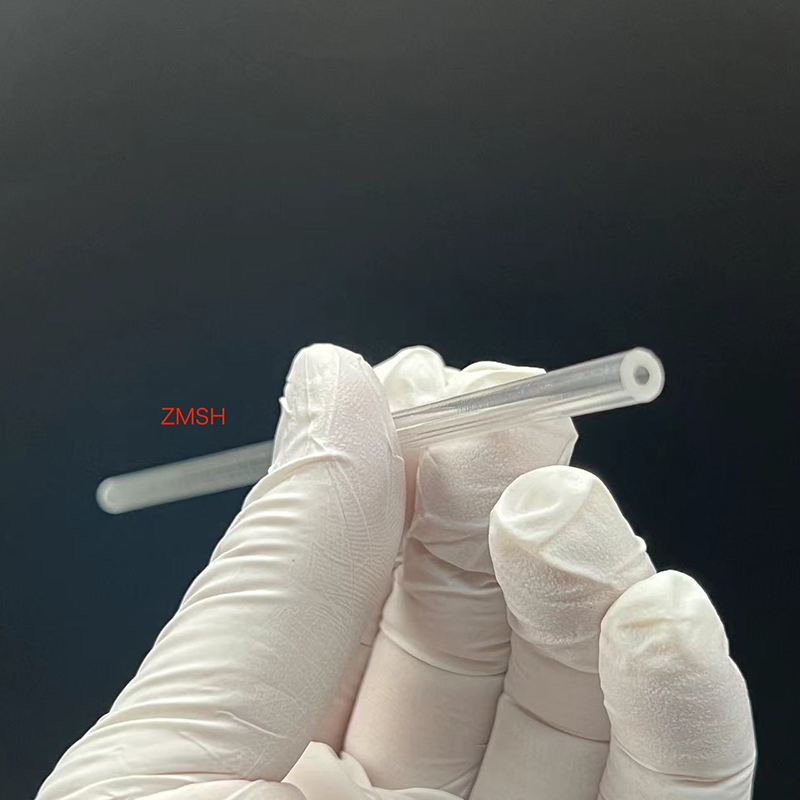

Emebere igwe makaotu akụkụ polishingihe dị iche iche siri ike na nke na-agbaji agbaji, gụnyere:

-

Silicon wafers maka ngwaọrụ semiconductor

-

Silicon carbide maka eletriki eletrik na ihe ndị na-emepụta LED

-

Sapphire wafers maka optoelectronics na kristal na-ekiri

-

Gallium arsenide maka ngwa eletrọnịkị dị elu

-

Germanium flakes maka infrared optics

-

Lithium niobate na lithium tantalate maka akụrụngwa piezoelectric

-

Mpempe iko maka ezigbo ngwa anya na ngwaọrụ nkwukọrịta

Ajụjụ A na-ajụkarị (FAQ) nke Ngwa Ntugharị Otu akụkụ

Q1: Kedu ihe nwere ike ịmegharị igwe na-egbuke egbuke nke otu akụkụ?

Igwe a dabara adaba maka wafer silicon, sapphire, silicon carbide, gallium arsenide, iko, na ihe ndị ọzọ na-emebi emebi.(Isi okwu: igwe na-egbuke egbuke, ihe na-agbaji agbaji)

Q2: Gịnị bụ ahụkarị polishing diski nha dị?

Dabere na usoro ahụ, diski polishing sitere na 820 mm ruo 1504 mm na dayameta.(Isi okwu: diski polishing, nha igwe)

Q3: Gịnị bụ ntụgharị ọnụego nke polishing diski?

Ọnụ ọgụgụ ntụgharị dị iche site na 50 ruo 80 rpm, dabere na ụdị.(Isiokwu: ọnụego ntụgharị, ọsọ na-egbu maramara)

Q4: Kedu ka usoro nchịkwa si eme ka mma polishing dị mma?

Igwe ahụ na-eji njikwa eletrọnịkị servo maka ntụgharị isi mekọrịtara ọnụ, na-ahụ na nrụgide otu na nsonaazụ kwụsiri ike.(Isi okwu: usoro njikwa, isi na-egbuke egbuke)

Q5: Gịnị bụ arọ na akara ukwu nke igwe?

Igwe igwe dị arọ sitere na tọn 2 ruo tọn 12, nwere akara ukwu n'etiti 1360 × 1330 × 2799 mm na 2350 × 2250 × 3050 mm.(Isi okwu: arọ igwe, nha)

Gbasara anyị

XKH na-ahụ maka mmepe teknụzụ dị elu, mmepụta na ire nke enyo anya pụrụ iche na ihe kristal ọhụrụ. Ngwaahịa anyị na-eje ozi ngwa anya eletrọnịkị, ngwa eletrọnịkị ndị ahịa na ndị agha. Anyị na-enye ngwa anya sapphire, mkpuchi oghere ekwentị mkpanaaka, ceramics, LT, Silicon Carbide SIC, Quartz, na kristal semiconductor. Site na nka nka na akụrụngwa dị oke ọnụ, anyị na-eme nke ọma na nhazi ngwaahịa na-abụghị ọkọlọtọ, na-achọ ịbụ onye na-eduga optoelectronic ihe ụlọ ọrụ teknụzụ dị elu.