Ngwa sapphire Windows Optical Sapphire ahaziri ahazi yana Polishing nkenke

Usoro nka

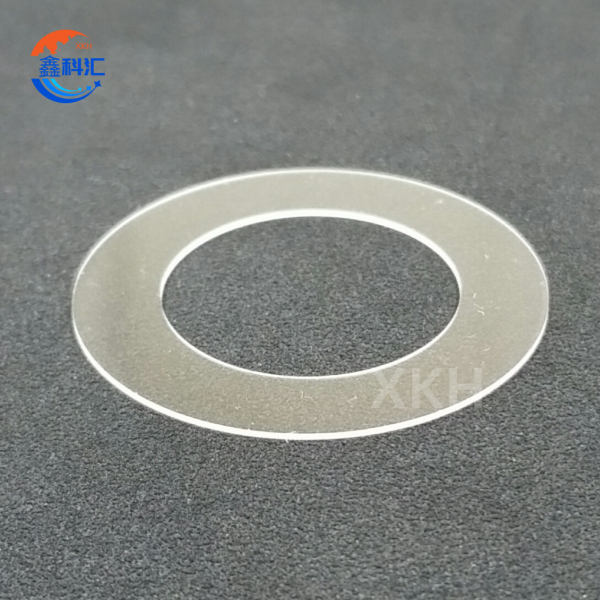

| Window sapphire | |

| Akụkụ | 8-400 mm |

| Nkwenye akụkụ | +0/-0.05mm |

| Ogo elu (nyochaa&gwuo) | 40/20 |

| Izi ezi nke elu | λ/10per @ 633nm |

| Kpochapụ oghere | >85%, 90% |

| Nkwenye nkwekọ | ±2''-±3'' |

| Bevel | 0.1-0.3mm |

| Mkpuchi | AR / AF / mgbe ndị ahịa rịọrọ |

Atụmatụ igodo

1.Material Superiority

· Njirimara Thermal emelitere: Na-egosiputa conductivity thermal nke 35 W / m · K (na 100 Celsius C), yana ọnụ ọgụgụ mgbasawanye ọkụ dị ala (5.3 × 10⁻⁶ / K) nke na-egbochi mgbagwoju anya anya n'okpuru ịgba ọsọ okpomọkụ. Ngwa ahụ na-edobe iguzosi ike n'ezi ihe n'ụdị ọbụna n'oge ntụgharị ọkụ ọkụ site na 1000 Celsius ruo okpomọkụ ụlọ n'ime sekọnd.

· Nkwụsi ike nke kemịkalụ: Na-egosipụta mmebi efu mgbe ekpughere ya na acids concentrated (HF ewepu) na alkalis (pH 1-14) maka ogologo oge, na-eme ka ọ dị mma maka akụrụngwa nhazi kemịkalụ.

· Ndozi anya: Site na uto kristal C-axis dị elu, na-enweta> 85% nnyefe na ụdị dị iche iche a na-ahụ anya (400-700nm) na mfu mgbasa n'okpuru 0.1% / cm.

Nhọrọ hyper-hemispherical polishing na-ebelata echiche elu ruo <0.2% kwa elu na 1064nm.

2.Precision Engineering Ike

Njikwa elu Nanoscale: Iji magnetorheological finishing (MRF), na-enweta ike dị elu <0.3nm Ra, dị oke egwu maka ngwa laser dị elu ebe LIDT gafere 10J/cm² na 1064nm, 10ns pulses.

Ngwakọta geometry mgbagwoju anya: Na-ejikọta 5-axis ultrasonic machining maka ịmepụta ọwa microfluidic (50μm obosara ndidi) na ihe dị iche iche anya (DOE) na <100nm atụmatụ mkpebi.

· Metrology Integration: Na-ejikọta interferometry na-acha ọcha na microscopy atomiki (AFM) maka njirimara elu 3D, na-eme ka ọdịdị ọdịdị dị <100nm PV gafee 200mm substrates.

Ngwa nke izizi

1.Defense Systems Enhancement

Ụlọ Hypersonic Vehicle: Emepụtara ka ọ nagide ibu ikuku nke Mach 5+ ka ọ na-ejigide nnyefe MWIR maka ndị isi na-achọ. Akara nanocomposite pụrụ iche na-egbochi delamination n'okpuru ibu ịma jijiji 15G.

Platforms Sensing Quantum: Ụdị birefringence dị ala (<5nm/cm) na-eme ka magnetometry ziri ezi na sistemụ nchọpụta okpuru mmiri.

2.Industrial Process Innovation

Semiconductor Extreme UV Lithography: Ọkwa AA na-egbu maramara mpio nke nwere <0.01nm n'elu ala siri ike belata EUV (13.5nm) mfu na-agbasa na sistemụ stepper.

Nyochaa Reactor Nuklia: Neutron-transparent variants (Al₂O₃ isotopically purified) na-enye nleba anya n'ezie na cores reactor Gen IV.

3.Emerging Technology Integration

comms Optical dabere na oghere: ụdị nke radieshọn siri ike (mgbe mkpughe gamma 1Mrad gasịrị) na-echekwa> 80% nnyefe maka njikọ njikọ laser satịlaịtị LEO.

Ihe ntanetị biophotonics: ọgwụgwọ elu nke bio-inert na-eme ka windo Raman spectroscopy kụnyere ya aka maka nlekota glucose na-aga n'ihu.

4.Advanced Energy Systems

Ihe nchọpụta Fusion Reactor: Multi-layer conductive coatings (ITO-AlN) na-enye ma nlele plasma na ihe nchebe EMI na nrụnye tokamak.

Ihe akụrụngwa hydrogen: Ụdị Cryogenic-ọkwa (nwalere na 20K) na-egbochi mbanye hydrogen na ebe nchekwa H₂ mmiri mmiri.

Ọrụ XKH & Ike inye

1.Custom Manufacturing Services

· Nhazi dabere na ịse: Na-akwado atụmatụ na-abụghị ọkọlọtọ (akụkụ 1 mm ruo 300 mm), nnyefe ngwa ngwa nke ụbọchị 20, yana prototyping oge mbụ n'ime izu anọ.

Ngwọta mkpuchi mkpuchi: Mgbochi nchegharị (AR), mgbochi mmejọ (AF), na mkpuchi mkpuchi ogologo ogologo (UV/IR) iji belata mfu ntụgharị uche.

· Nchacha nke ọma & Nnwale: polishing-ọkwa atọ na-enweta ≤0.5 nm ịdị nro n'elu, yana interferometry na-eme ka nnabata λ/10 dị larịị.

2.Supply Chain & Teknụzụ Nkwado

· Njikọ kwụ ọtọ: njikwa usoro zuru oke site na uto kristal (usoro Czochralski) na-egbutu, polishing, na mkpuchi, na-ekwe nkwa ịdị ọcha nke ihe (efu-/oke-free) na nkwụsi ike ogbe.

· Mmekọrịta ụlọ ọrụ: Ndị ọrụ nkwekọrịta ụgbọ elu kwadoro; jikọtara ya na CAS iji wuo usoro heterostructures superlatice maka nnọchi ụlọ.

3.Product Pọtụfoliyo & Logistics

· Ndepụta ọkọlọtọ: 6-inch ruo 12-inch wafer formats; Ọnụ ahịa otu site na 43to82 (nha / mkpuchi mkpuchi), yana mbupu otu ụbọchị.

· Ndụmọdụ maka nka maka ụdị ngwa-ngwa (dịka ọmụmaatụ, windo steepụ maka ọnụ ụlọ agụụ, ụlọ na-eguzogide ujo).