Bionic na-adịghị slip pad wafer na-ebu vacuum sucker friction pad sucker

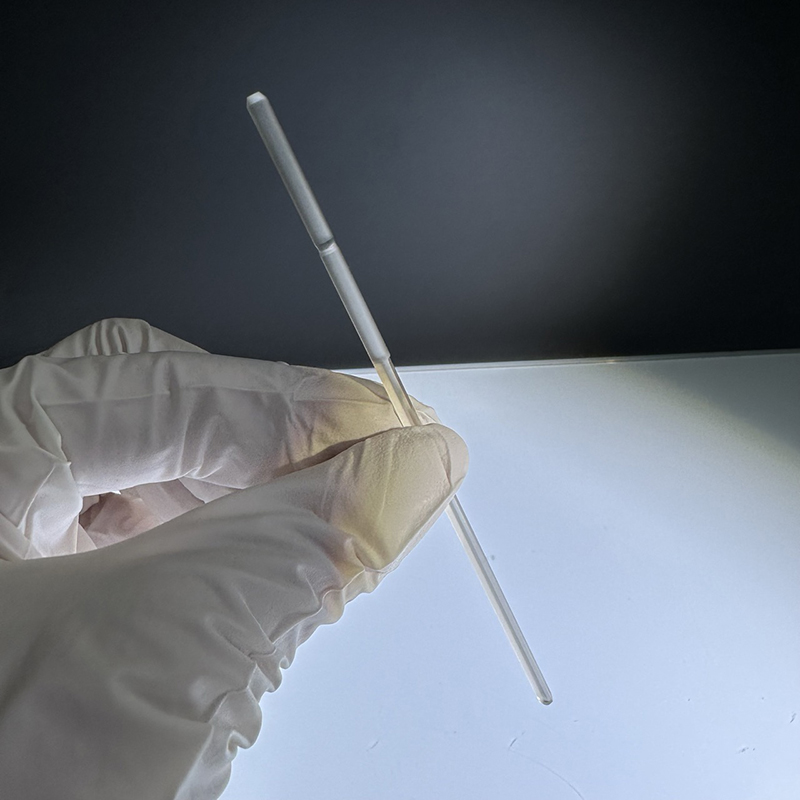

Njirimara mgbochi-slip bionic:

• Iji ihe mejupụtara elastomer injinịa pụrụ iche, iji nweta ihe ọ bụla fọdụrụnụ, mmetụta mgbochi skid dị ọcha na-enweghị mmetọ, zuru oke maka chọrọ gburugburu nrụpụta semiconductor.

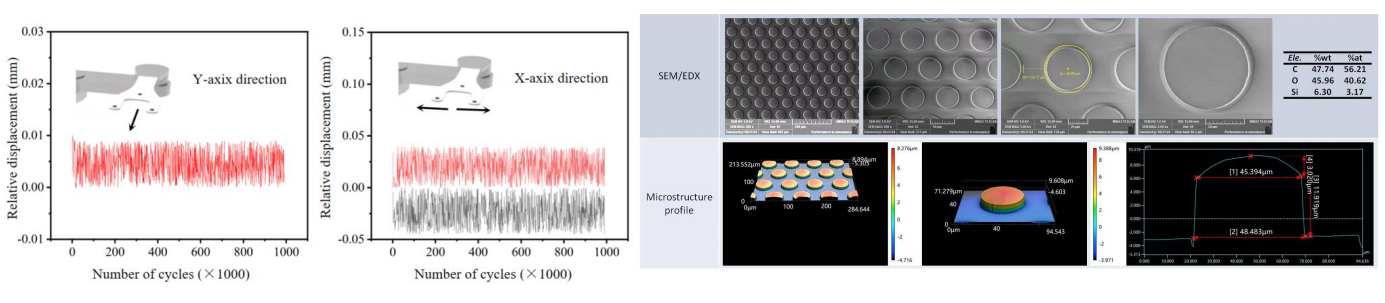

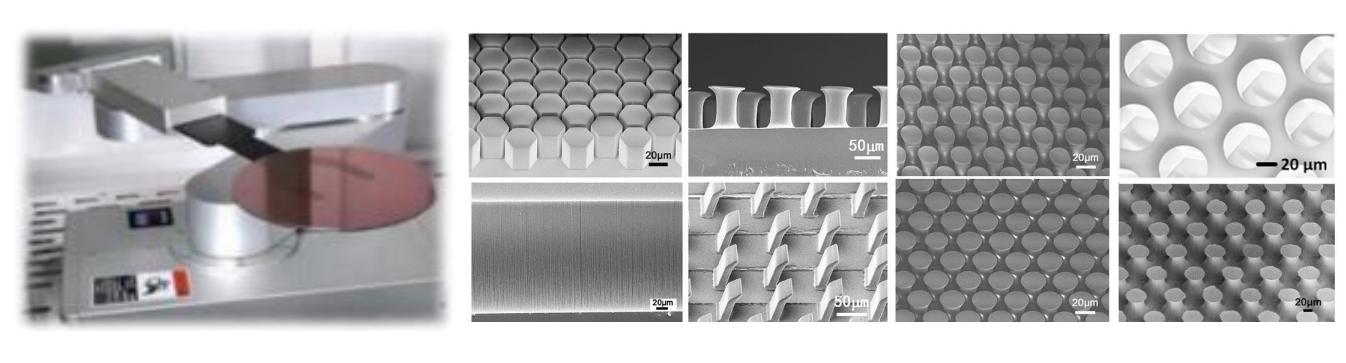

• Site nkenke micro-nano Ọdịdị n'usoro imewe, ọgụgụ isi akara nke elu esemokwu e ji mara, mgbe ịnọgide na-enwe elu esemokwu ọnụọgụ mgbe ọbọ ultra-ala adhesion.

• Pụrụ iche interface mechanics imewe na-enyere magburu onwe arụmọrụ nke ma elu tangential esemokwu (μ>2.5) na ala nkịtị adhesion (<0.1N/cm²).

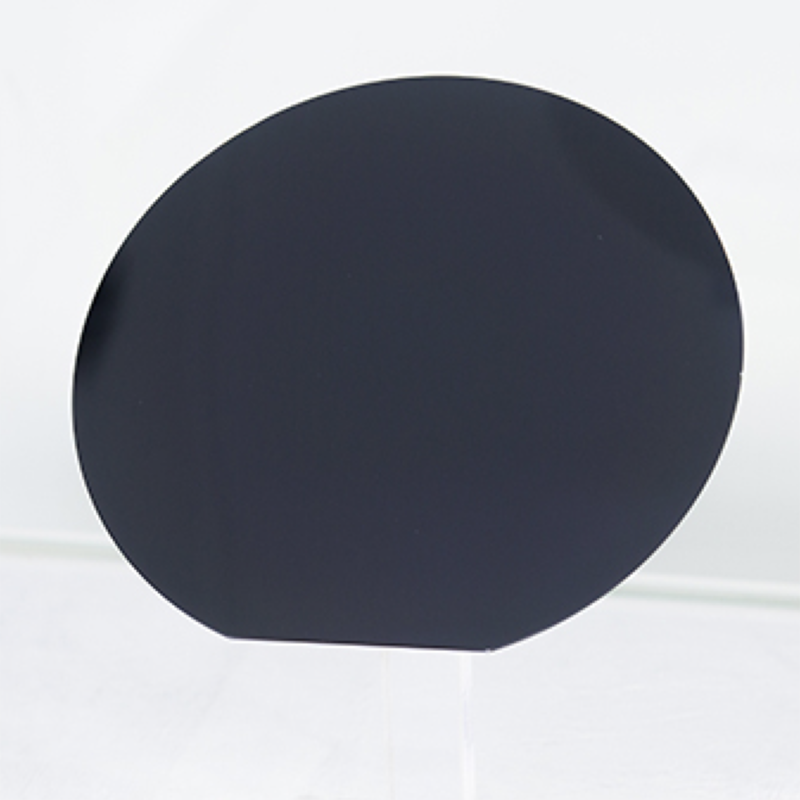

• Ihe polymer mepụtara nke ọma maka ụlọ ọrụ semiconductor, nke na-arụ ọrụ kwụsiri ike na-enweghị attenuation maka 100,000 reuses site na teknụzụ mmepụta micro na nano.

Ngwa mgbochi slip pad bionic:

(1) Ụlọ ọrụ Semiconductor

1. Nrụpụta wafer:

· Ndokwa na-adịghị amị amị n'oge nnyefe nke wafers ultra-thin ruo 12 inch (50-300μm)

· Ndozi nke ọma nke onye na-ebu wafer nke igwe lithography

· Wafer na-adịghị amị amị maka akụrụngwa nnwale

2. Nnwale ngwugwu:

· Ndozi na-adịghị emebi emebi nke silicon carbide / galium nitride ike ngwaọrụ

Ihe nchekwa mgbochi-slip n'oge mgbawa mgbawa

Nwalee ujo na mwepu nkwụsị nke tebụl nyocha

(2) Ụlọ ọrụ fotovoltaic

1. Nhazi silicon wafer:

· Ndozi na-adịghị amị amị n'oge mbelata mkpanaka silicon monocrystalline

· Ultra-kpakpa silicon wafer (<150μm) nnyefe na-adịghị ele

· Silicon wafer n'ọnọdu igwe na-ebi akwụkwọ ihuenyo

2. Mkpokọta akụrụngwa:

· Igwe azụ ụgbọ elu laminated anaghị amị amị

· Ndokwa nrụnye etiti

· Igbe njikọ edozi

(3) ụlọ ọrụ fotoelectric

1. panel ngosi:

· Usoro mkpụrụ iko OLED/LCD na-adịghị amị amị

· Ndokwa nke ọma nke dabara na polarizer

· Ngwa ihe na-egosi ihe ịma jijiji na skid proof

2. Ngwa anya:

· Mgbakọ modul lens na-enweghị nkwụsị

· Ndozi prism / mirror

· Sistemụ ngwa anya laser na-ama jijiji

(4) Ngwá ọrụ nkenke

1. Igwe ikpo okwu ziri ezi nke igwe lithography bụ ihe mgbochi

2. Tebụl nha nke akụrụngwa nchọpụta bụ ihe na-egosi ujo

3. Akpaaka akụrụngwa n'ibu ogwe aka na-adịghị ele

Data teknụzụ:

| Ngwakọta ihe: | C, O, Si |

| Ike ike mmiri (A): | 50-55 |

| Ọnụ ego mgbake na-agbanwe: | 1.28 |

| Okpomọkụ nnabata dị elu: | 260 ℃ |

| Ọnụọgụ esemokwu: | 1.8 |

| Nguzogide PLASMA: | Ndidi |

Ọrụ XKH:

XKH na-enye ọrụ nhazi nhazi nke bionic anti-slip mat zuru oke, gụnyere nyocha ihe achọrọ, imewe atụmatụ, ịgba akaebe ngwa ngwa na nkwado mmepụta oke. N'ịdabere na nkà na ụzụ mmepụta micro na nano, XKH na-enye ngwọta mgbochi nkwụsị nke ọkachamara maka ụlọ ọrụ semiconductor, fotovoltaic na fotoelectric, ma nyere ndị ahịa aka imezu mmetụta dị ịrịba ama dị ka mbelata ọnụ ahịa irighiri ihe ruo 0.005% na mmụba na-abawanye site na 15%.

Eserese zuru ezu