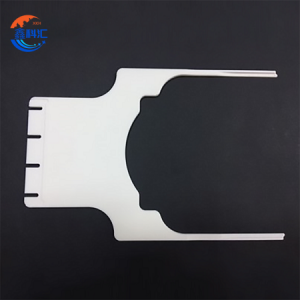

Alumina Ceramic End Effector / Fork Arm maka Wafer na njikwa mkpụrụ

Eserese zuru ezu

Nchịkọta nke Alumina Ceramic End Effector

Alumina Ceramic End Effector, nke a na-akpọkarị ogwe aka ndụdụ seramiiki ma ọ bụ seramiiki gripper, bụ ngwa dị oke mkpa ejiri na akpaaka roboti na ahịrị mmepụta ụlọ dị ọcha. A na-etinye Alumina Ceramic End Effector na ogwe aka roboti dị ka interface ikpeazụ na ngwaahịa ahụ, na-ahụ maka ịtụtụ, ijide, ịhazi na ịnyefe akụkụ ndị nwere mmetụta dị ukwuu dị ka silicon wafers, iko iko, ma ọ bụ microelectronic components.

Emepụtara site na seramiiki ultra-dị ọcha alumina (Al2O3), ogwe aka ndụdụ a na-enye ihe ngwọta dị ọcha na nke kwụsiri ike maka gburugburu ebe enweghị mmerụ metal, nrụrụ plastik, ma ọ bụ ọgbọ irighiri ihe.

Ngwongwo ihe - Ihe kpatara Alumina

Banyere Alumina Ceramic End Effector, Alumina (Al2O3) bụ otu n'ime ndị kacha guzosie ike na ntụkwasị obi.elu engineering ceramik. Ọkwa anyị na-eji (≥99.5% ịdị ọcha) na-enye ngwakọta pụrụ iche nke àgwà anụ ahụ na kemịkal nke na-eme ka ọ bụrụ ihe nhọrọ maka semiconductor na ngwa agụụ:

-

Oke isi ike- Site na ọkwa ike Mohs nke 9, ọ na-enye ogologo oge na nguzogide ọkọ.

-

Ntachi obi nke thermal- Na-edobe iguzosi ike n'ezi ihe n'ihe karịrị 1600 Celsius C, na-arụ ọrụ nke metal na polymer.

-

Ihe mkpuchi eletrik- Na-ewepụ nrụpụta static ma na-enye nchebe dielectric zuru oke.

-

Mgbochi kemịkalụ- Acids, alkalis, gas plasma na-adịghị emetụta ya na ngwọta nhicha ike.

-

Ihe egwu mmetọ dị obere- Igwe anaghị apụ apụ, elu esemokwu dị ala nke na-ebelata mwepụta ahụ n'ime ụlọ dị ọcha.

Àgwà ndị a na-ekwe ka alumina seramiiki na-eme ka njedebe na-arụ ọrụ na-enweghị ntụpọ na gburugburu ebe siri ike, dị elu.

Ngwa isi nke Alumina Ceramic End Effector

Ntughari nke alumina ceramic end effectorfork ogwe aka na-eme ka ha dị mkpa n'ọtụtụ ụlọ ọrụ teknụzụ dị elu:

-

Semiconductor wafer usoro njem- Na-ebugharị silicon wafers site na usoro gaa na nhazi na-enweghị micro-scratches.

-

Ngosipụta ihuenyo dị larịị- Ijikwa ihe iko iko na-esighi ike maka imepụta OLED, LCD ma ọ bụ microLED.

-

Imepụta fotovoltaic (PV).- Na-akwado ịkwanye wafer nke anyanwụ na ịkwatu n'okpuru okirikiri roboti na-agba ọsọ.

-

Mgbakọ akụrụngwa na eletrọnịkị- Na-ejide akụkụ ndị siri ike dị ka sensọ, resistors na obere ibe.

-

Vacuum na ime ụlọ dị ọcha- Na-arụ ọrụ nkenke na ọnọdụ dị ọcha, nke na-achịkwa akụkụ.

N'ọnọdụ ọ bụla, Alumina Ceramic End Effector na-enye njikọ dị mkpa n'etiti akpaaka roboti na ngwaahịa a na-ebugharị.

Nhọrọ imewe na nhazi nke Alumina Ceramic End Effector

Ahịrị mmepụta ọ bụla nwere ihe pụrụ iche chọrọ. Ya mere, anyị na-enye ihe ngwọta Alumina Ceramic End Effector nke a na-akwa akwa maka nha wafer dị iche iche, usoro roboti, na ụzọ njikwa:

Ndakọrịta Wafer: Na-ejide wafers site na 2 "ruo 12" ma nwee ike ịkwado maka akụkụ omenala.

Nhọrọ geometry: ndụdụ otu, ndụdụ abụọ, oghere ọtụtụ, ma ọ bụ ụdị ahaziri iche nwere ebe ezumike agbakwunyere.

Ijikwa Vacuum: Ọwa mmịpụta nke nhọrọ maka nkwado wafer na-enweghị kọntaktị.

Ntụnye ugwu: oghere bolt ahaziri ahazi, flanges, ma ọ bụ atụmatụ nwere oghere iji dabara na ogwe aka rọbọt ọ bụla.

Elu mechapụrụ: Ebe a na-ehichapụrụ ma ọ bụ mechaa nke ukwuu (ruo Ra <0.15 μm).

Profaịlụ ihu: akụkụ chamfered ma ọ bụ gburugburu maka nchekwa wafer kacha.

Anyị Alumina Ceramic End Effector engineering Team nwere ike na-arụ ọrụ site na ndị ahịa CAD eserese ma ọ bụ sample akụkụ, n'ịhụ enweghị nkebi mwekota n'ime ẹdude automation usoro.

Uru isi nke Alumina ceramic End Effectors

| Njirimara | Ihe Mere O Ji Dị Mkpa |

|---|---|

| Nkenkenke akụkụ | Na-edobe nhazi zuru oke ọbụlagodi n'ọsọ ọsọ dị elu, usoro okirikiri ugboro ugboro. |

| Na-adịghị emerụ | Na-emepụta ihe fọrọ nke nta ka ọ bụrụ ihe ọ bụla, na-egbo mkpa ụlọ dị ọcha. |

| Okpomọkụ na ihe akaebe corrosion | Na-atachi obi na usoro nhazi ike na ihe egwu ọkụ. |

| Enweghị ụgwọ kwụ ọtọ | Na-echebe wafers na ihe ndị nwere mmetụta n'ihe egwu electrostatic. |

| Dị fechaa ma sie ike | Na-enye isi ike dị elu na-emebighị ibu ogwe aka roboti. |

| Ndụ ọrụ agbatịkwuru | Na-egosipụta ogwe aka metal na polymer n'ogologo ndụ yana ntụkwasị obi. |

Ntụle ihe nke Alumina Ceramic End Effector

| Njirimara | Ogwe aka ndụdụ plastik | Aluminom/Metal ndụdụ ogwe aka | Alumina Ceramic Fork Arm |

|---|---|---|---|

| Isi ike | Dị ala | Ọkara | Dị Elu |

| Oke okpomọkụ | ≤150C | ≤500C | Ruo 1600 ° C |

| Kemịkalụ kwụsie ike | Ogbenye | Na-agafeghị oke | Magburu onwe |

| Ogo ime ụlọ ọcha | Dị ala | Nkezi | Kwesịrị ekwesị maka Klas 100 ma ọ bụ karịa |

| Yiri Nguzogide | Oke | Ọ dị mma | pụtara ìhè |

| Ọkwa nhazi | Na-agafeghị oke | Oke | Ọbara |

Ajụjụ A na-ajụkarị (FAQ) nke Alumina Ceramic End Effector

Q1: Kedu ihe na-eme ka njedebe alumina seramiiki dị iche na nke ígwè?

A1:N'adịghị ka aluminom ma ọ bụ ogwe aka nchara, seramiiki alumina anaghị emebi emebi, mebie ma ọ bụ webata ion ọla n'ime usoro semiconductor. Ọ na-anọgide na-akwụsi ike n'okpuru ọnọdụ dị oke egwu ma na-ewepụta ihe fọrọ nke nta ka ọ bụrụ ihe ọ bụla.

Q2: Enwere ike iji Alumina Ceramic End Effector mee ihe na oghere dị elu na ụlọ plasma?

A2:Ee. Alumina seramiiki bụna-abụghị outgasna-eguzogide ọgwụ na plasma, nke na-eme ka ọ bụrụ ihe a na-ahọrọ maka nhazi oghere na ngwa etching.

Q3: Kedu ka ogwe aka ndụdụ Alumina Ceramic End Effector nwere ike ịhazi?

A3:Unit ọ bụla nwere ike ịbụahaziri nke ọma—gụnyere udi, oghere, oghere mmiri, ụdị mgbago elu, na ngwụcha ọnụ—iji kwekọọ n'ihe sistemu roboti gị chọrọ.

Q4: Ha na-esighi ike?

A4:Ọ bụ ezie na seramiiki nwere ndakpọ eke, injinịa imewe anyị na-ekesa ibu nke ọma ma na-ebelata isi ihe nrụgide. Mgbe ejiri ya nke ọma, ndụ ọrụ na-adịkarị karịa nke metal ma ọ bụ polymer ọzọ.

Gbasara anyị

XKH na-ahụ maka mmepe teknụzụ dị elu, mmepụta na ire nke enyo anya pụrụ iche na ihe kristal ọhụrụ. Ngwaahịa anyị na-eje ozi ngwa anya eletrọnịkị, ngwa eletrọnịkị ndị ahịa na ndị agha. Anyị na-enye ngwa anya sapphire, mkpuchi oghere ekwentị mkpanaaka, ceramics, LT, Silicon Carbide SIC, Quartz, na kristal semiconductor. Site na nka nka na akụrụngwa dị oke ọnụ, anyị na-eme nke ọma na nhazi ngwaahịa na-abụghị ọkọlọtọ, na-achọ ịbụ onye na-eduga optoelectronic ihe ụlọ ọrụ teknụzụ dị elu.