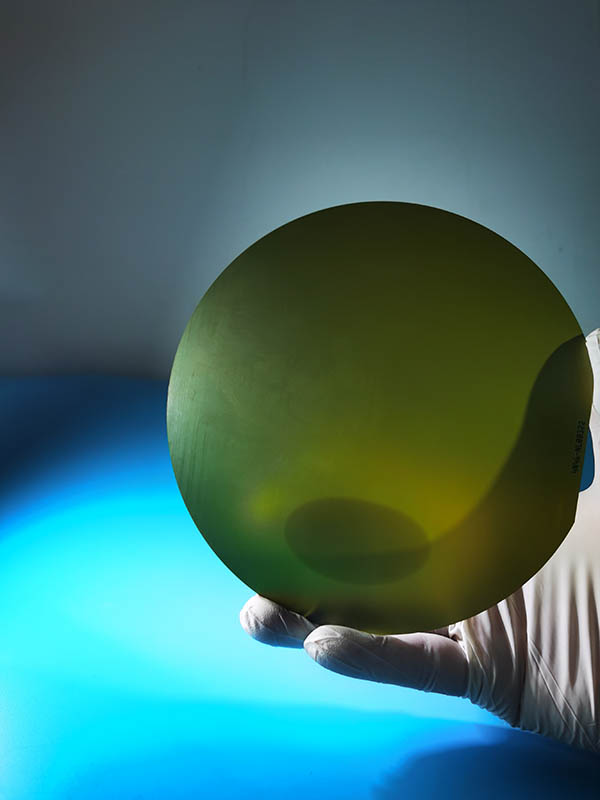

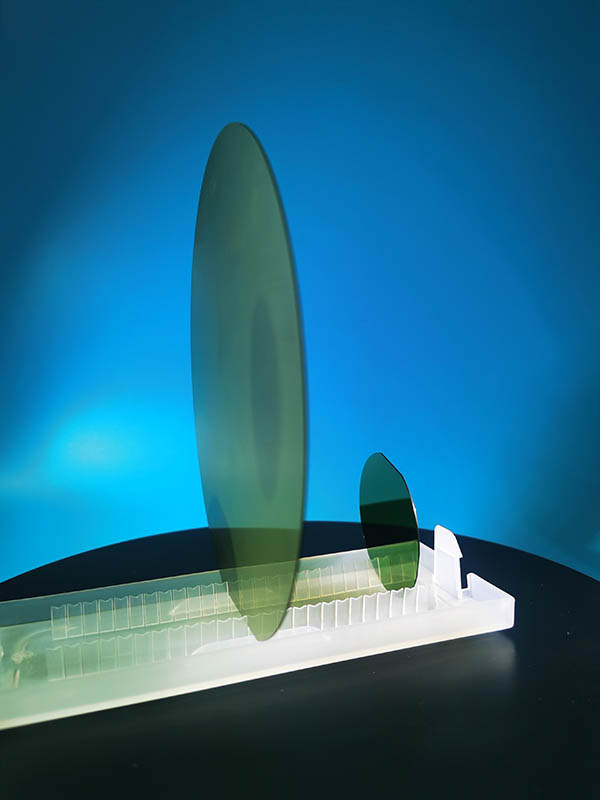

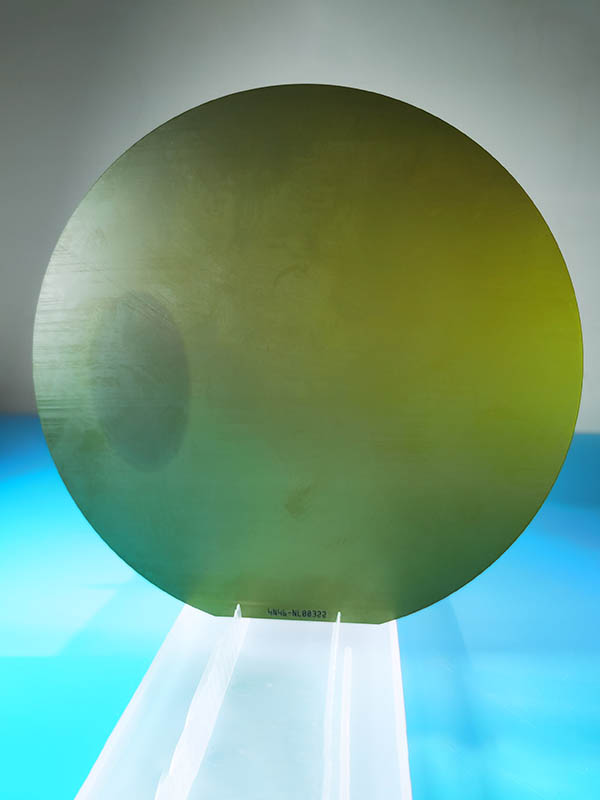

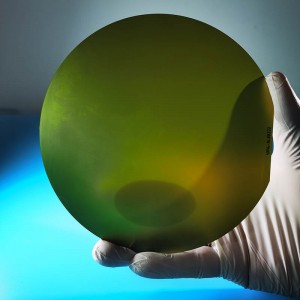

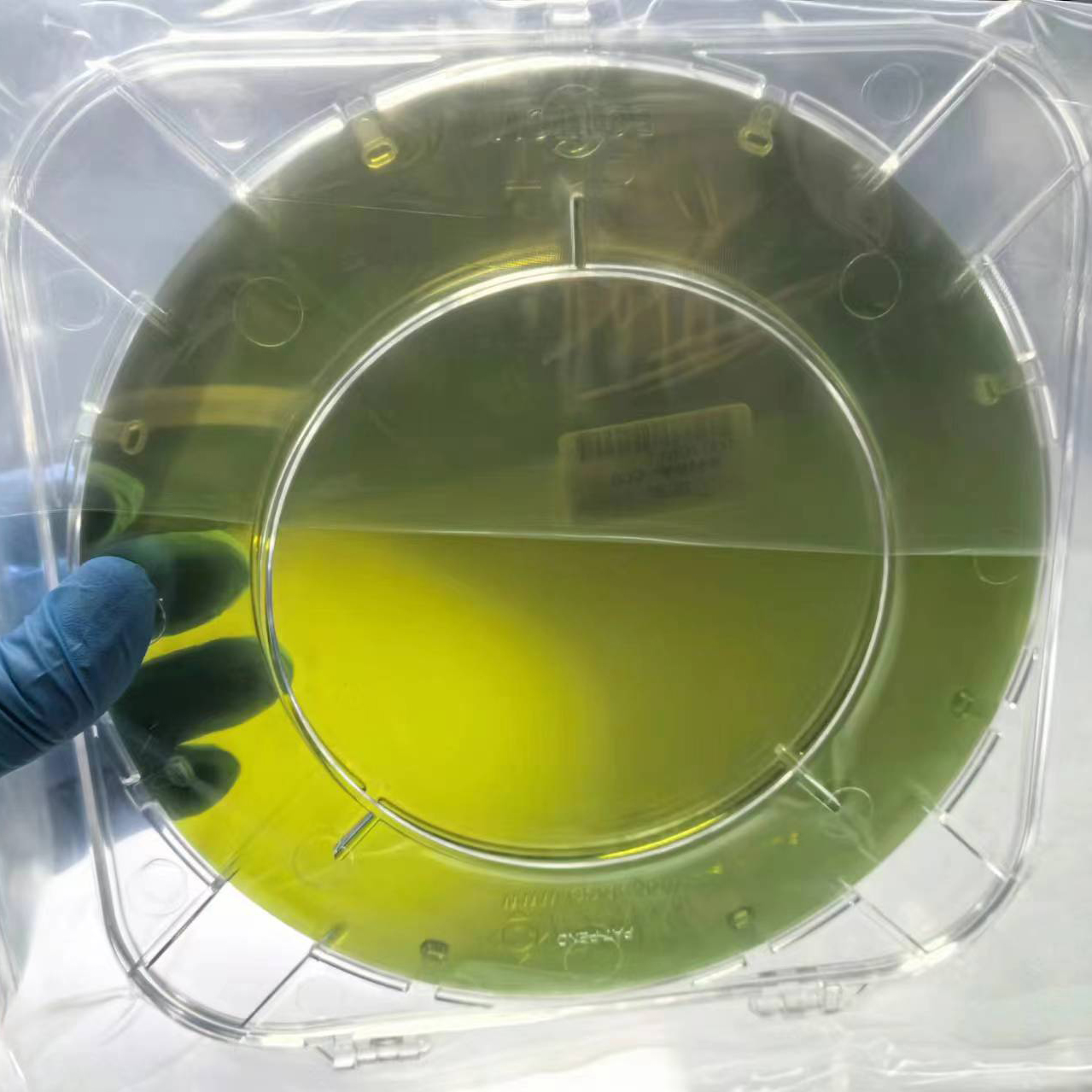

8Inch 200mm 4H-N SiC Wafer Conductive dummy nyocha ọkwa

N'ihi ihe pụrụ iche nke anụ ahụ na nke eletrọnịkị, a na-eji 200mm SiC wafer semiconductor ihe na-emepụta ihe na-arụ ọrụ dị elu, okpomọkụ dị elu, radieshon na-eguzogide, na ngwa ngwa eletrik dị elu. Ọnụ ahịa mkpụrụ mkpụrụ 8inch SiC na-ebelata nke nta nke nta ka teknụzụ na-abawanyewanye ma ọchịchọ na-eto. Mmepe teknụzụ na-adịbeghị anya na-eduga n'ichepụta nha nke 200mm SiC wafers. Uru ndị bụ isi nke SiC wafer semiconductor ihe ma e jiri ya tụnyere Si na GaAs wafers: Ike ọkụ eletrik nke 4H-SiC n'oge mbibi oke mmiri karịrị usoro ịdị elu karịa ụkpụrụ kwekọrọ maka Si na GaAs. Nke a na-eduga na mbelata dị ukwuu na resistivity na steeti Ron. Obere na steeti resistivity, jikọtara ya na njupụta dị ugbu a na thermal conductivity, na-enye ohere iji obere obere anwụ maka ngwaọrụ ike. Igwe ọkụ dị elu nke SiC na-ebelata nguzogide okpomọkụ nke mgbawa. Ngwongwo eletrọnịkị nke ngwaọrụ dabere na SiC wafers kwụsiri ike karịa oge na nkwụsi ike okpomọkụ, nke na-eme ka ntụkwasị obi dị elu nke ngwaahịa. Silicon carbide na-eguzogide ọgwụ siri ike na radieshon siri ike, nke na-adịghị emebi ihe ndị eletrọnịkị nke mgbawa. Okpomọkụ dị elu na-arụ ọrụ nke kristal (karịa 6000C) na-enye gị ohere ịmepụta ngwaọrụ ndị a pụrụ ịdabere na ya nke ukwuu maka ọnọdụ arụ ọrụ siri ike na ngwa pụrụ iche. Ugbu a, anyị nwere ike ịnye obere ogbe 200mmSiC wafers na-aga n'ihu na-aga n'ihu ma nwee ụfọdụ ngwaahịa na ụlọ nkwakọba ihe.

Nkọwapụta

| Nọmba | Ihe | Nkeji | Mmepụta | Nnyocha | Dummy |

| 1. Parameters | |||||

| 1.1 | polytype | -- | 4H | 4H | 4H |

| 1.2 | nghazi elu | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Igwe ọkụ eletrik | |||||

| 2.1 | dopant | -- | n-ụdị Nitrogen | n-ụdị Nitrogen | n-ụdị Nitrogen |

| 2.2 | resistivity | ohm · cm | 0.015-0.025 | 0.01-0.03 | NA |

| 3. Mechanical paramita | |||||

| 3.1 | dayameta | mm | 200±0.2 | 200±0.2 | 200±0.2 |

| 3.2 | ọkpụrụkpụ | μm | 500± 25 | 500± 25 | 500± 25 |

| 3.3 | Ntughari notch | ° | [1-100]±5 | [1-100]±5 | [1-100]±5 |

| 3.4 | Omimi Ọkwa | mm | 1-1.5 | 1-1.5 | 1-1.5 |

| 3.5 | LTV | μm | ≤5 (10mm*10mm) | ≤5 (10mm*10mm) | ≤10 (10mm*10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Ụta | μm | -25-25 | -45-45 | -65-65 |

| 3.8 | Warp | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | ≤0.2 | ≤0.2 | ≤0.2 |

| 4. Ihe owuwu | |||||

| 4.1 | njupụta micropipe | ihe / cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | ígwè ọdịnaya | atom / cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | ihe / cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | ihe / cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | ihe / cm2 | ≤7000 | ≤10000 | NA |

| 5. Mma mma | |||||

| 5.1 | n'ihu | -- | Si | Si | Si |

| 5.2 | elu imecha | -- | Si-ihu CMP | Si-ihu CMP | Si-ihu CMP |

| 5.3 | urughuru | ea/wafer | ≤100 (nha≥0.3μm) | NA | NA |

| 5.4 | ọkọ | ea/wafer | ≤5, ngụkọta ogologo≤200mm | NA | NA |

| 5.5 | Ọnụ ibe / indents / mgbawa / ntụpọ / mmetọ | -- | Ọ dịghị | Ọ dịghị | NA |

| 5.6 | Mpaghara polytype | -- | Ọ dịghị | Mpaghara ≤10% | Mpaghara ≤30% |

| 5.7 | akara n'ihu | -- | Ọ dịghị | Ọ dịghị | Ọ dịghị |

| 6. Azụ àgwà | |||||

| 6.1 | azụ imecha | -- | C-ihu MP | C-ihu MP | C-ihu MP |

| 6.2 | ọkọ | mm | NA | NA | NA |

| 6.3 | Akụkụ ntụpọ azụ ibe / indents | -- | Ọ dịghị | Ọ dịghị | NA |

| 6.4 | Azụ isi ike | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Akara azụ | -- | Ọkwa | Ọkwa | Ọkwa |

| 7. Nri | |||||

| 7.1 | onu | -- | Chamfer | Chamfer | Chamfer |

| 8. ngwugwu | |||||

| 8.1 | nkwakọ ngwaahịa | -- | Epi-njikere na agụụ nkwakọ ngwaahịa | Epi-njikere na agụụ nkwakọ ngwaahịa | Epi-njikere na agụụ nkwakọ ngwaahịa |

| 8.2 | nkwakọ ngwaahịa | -- | Multi-wafer ngwugwu cassette | Multi-wafer ngwugwu cassette | Multi-wafer ngwugwu cassette |

Eserese zuru ezu