6 inch na-eduzi otu kristal SiC na polycrystalline SiC composite substrate dayameta 150mm P ụdị N

Usoro nka

| Nha: | 6 inch |

| Dayameta: | 150 mm |

| Ọkpụrụkpụ: | 400-500 μm |

| Ihe ngosi ihe nkiri Monocrystalline SiC | |

| Ụdị Poly: | 4H-SiC ma ọ bụ 6H-SiC |

| Ntụkwasị obi nke Doping: | 1 × 10¹⁴ - 1 × 10¹⁸ cm |

| Ọkpụrụkpụ: | 5-20 μm |

| Nguzogide mpempe akwụkwọ: | 10-1000 Ω/sq |

| Mbugharị eletrọn | 800-1200 cm²/Vs |

| Mbugharị oghere: | 100-300 cm²/Vs |

| Parameters nke polycrystalline SiC Buffer Layer | |

| Ọkpụrụkpụ: | 50-300 μm |

| Nrụpụta okpomọkụ: | 150-300 W/m·K |

| Monocrystalline SiC Substrate Parameters | |

| Ụdị Poly: | 4H-SiC ma ọ bụ 6H-SiC |

| Ntụkwasị obi nke Doping: | 1 × 10¹⁴ - 1 × 10¹⁸ cm |

| Ọkpụrụkpụ: | 300-500 μm |

| Nha ọka: | > 1 mm |

| Ọdịiche dị n'elu: | <0.3 mm RMS |

| Mechanical & Eletriki Njirimara | |

| Isi ike: | 9-10 Mohs |

| Ike mkpakọ: | 3-4 GPA |

| Ike ọdụdọ: | 0.3-0.5 GPA |

| Ike ubi mgbawa: | > 2 MV / cm |

| Mkpokọta nnabata dose: | > 10 Mr |

| Nguzogide Mmetụta Otu Omume: | > 100 MeV·cm²/mg |

| Nrụpụta okpomọkụ: | 150-380 W/m·K |

| Oke okpomoku na-arụ ọrụ: | -55 ruo 600 Celsius |

Njirimara isi

SiC monocrystalline nke anụ ọhịa 6 na-eduzi na mkpụrụ osisi polycrystalline SiC na-enye nguzozi pụrụ iche nke nhazi ihe na arụmọrụ, na-eme ka ọ dabara maka gburugburu ụlọ ọrụ na-achọsi ike:

1.Cost-Effectiveness: The polycrystalline SiC base substantially ebelata ụgwọ ma e jiri ya tụnyere monocrystalline SiC zuru ezu, ebe monocrystalline SiC na-arụ ọrụ oyi akwa na-eme ka arụmọrụ-ọkwa ngwaọrụ, dị mma maka ngwa na-efu efu.

2.Exceptional Eletriki Properties: The monocrystalline SiC Layer na-egosiputa elu ụgbọelu na-ebugharị (> 500 cm² / V·s) na njupụta ntụpọ dị ala, na-akwado ọrụ ngwaọrụ dị elu na ike dị elu.

3.High-Temperature Stability: SiC's inherent high- okpomọkụ resistance (> 600 ° C) na-eme ka ihe ndị mejupụtara mejupụtara na-anọgide na-adịgide adịgide n'okpuru ọnọdụ dị oke egwu, na-eme ka ọ dị mma maka ụgbọ ala eletrik na ngwa moto ụlọ ọrụ.

4.6-inch Standardized Wafer Size: Tụnyere omenala 4-inch SiC substrates, usoro 6-inch na-abawanye mkpụrụ mgbawa site na 30%, na-ebelata ọnụ ahịa ngwaọrụ otu otu.

5.Conductive Design: Pre-doped N-ụdị ma ọ bụ P-ụdị n'ígwé belata ion implantation nzọụkwụ na ngwaọrụ n'ichepụta, na-eme ka mmepụta arụmọrụ na mkpụrụ.

6.Superior Thermal Management: The polycrystalline SiC base's thermal conductivity (~ 120 W / m·K) na-abịaru nso na nke monocrystalline SiC, na-edozi ihe ịma aka nke ikpo ọkụ ọkụ na ngwaọrụ dị elu.

Njirimara ndị a na-edobe 6-inch conductive monocrystalline SiC na polycrystalline SiC composite substrate dị ka ihe ngwọta asọmpi maka ụlọ ọrụ dịka ike mmeghari ohuru, njem ụgbọ oloko, na ikuku.

Ngwa nke izizi

SiC monocrystalline nke anụ ọhịa isii na-arụ ọrụ na polycrystalline SiC composite substrate ka etinyegoro nke ọma n'ọtụtụ mpaghara achọrọ dị elu:

1.Electric Vehicle Powertrains: Ejiri ya na SiC MOSFET dị elu na diodes iji kwalite arụmọrụ inverter na ịgbatị batrị (dịka, Tesla, ụdị BYD).

2.Industrial Motor Drives: Na-eme ka ọnọdụ okpomọkụ dị elu, na-agbanwe agbanwe-ugboro modul, na-ebelata ike ike na ígwè ọrụ dị arọ na ikuku ikuku.

3.Photovoltaic Inverters: Ngwa SiC na-emeziwanye arụmọrụ ngbanwe nke anyanwụ (> 99%), ebe mkpụrụ ihe mejupụtara na-ebelata ụgwọ ọrụ usoro.

4.Rail Transportation: A na-etinye ya na ndị na-atụgharị traction maka ụgbọ okporo ígwè na usoro ụgbọ oloko dị elu, na-enye nguzogide voltaji dị elu (> 1700V) na ụdị kọmpat.

5.Aerospace: Ezigbo maka sistemu ike satịlaịtị na sekit njikwa ụgbọ elu, nke nwere ike iguzogide oke okpomọkụ na radieshon.

N'ichepụta ihe bara uru, SiC monocrystalline nke anụ ọhịa isii na polycrystalline SiC composite substrate dabara nke ọma na usoro ngwaọrụ SiC ọkọlọtọ (dịka ọmụmaatụ, lithography, etching), na-achọghị itinye ego ego ọzọ.

Ọrụ XKH

XKH na-enye nkwado zuru oke maka 6-inch conductive monocrystalline SiC na polycrystalline SiC composite substrate, na-ekpuchi R&D iji mepụta oke:

1.Customization: Mgbanwe monocrystalline oyi akwa ọkpụrụkpụ (5-100 μm), doping ịta (1e15-1e19 cm⁻³), na crystal orientation (4H/6H-SiC) izute iche iche ngwaọrụ chọrọ.

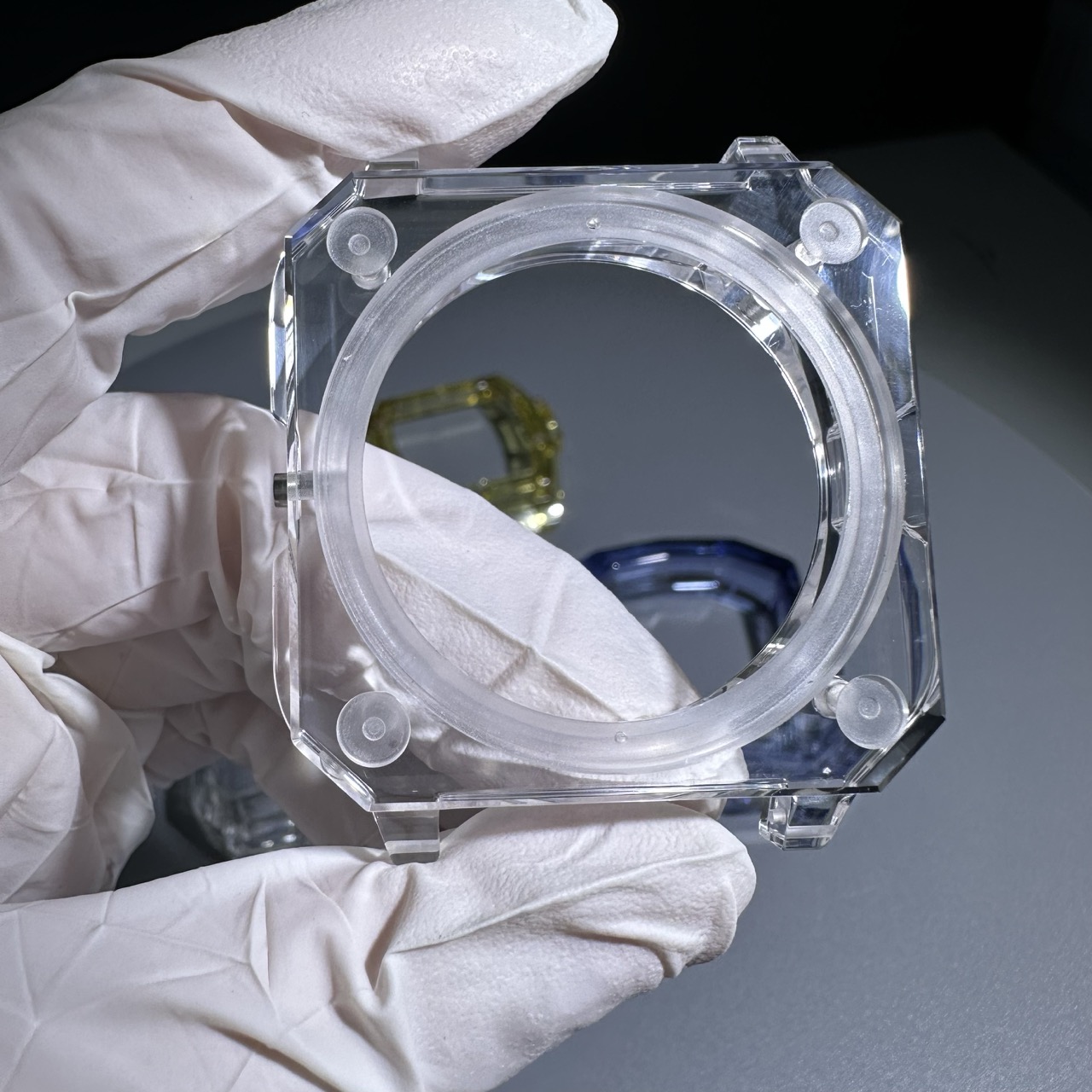

2.Wafer Processing: Nnukwu ọkọnọ nke 6-inch substrates na backside thinning na metallization ọrụ maka nkwụnye-na-play mwekota.

3.Technical Validation: Gụnyere XRD crystallinity analysis, Ụlọ Nzukọ mmetụta ule, na thermal iguzogide nha iji mee ngwa ngwa iru eru.

4.Rapid Prototyping: 2- na 4-inch samples (otu usoro) maka ụlọ ọrụ nyocha iji mee ka usoro mmepe mmepe dịkwuo elu.

5.Failure Analysis & Optimization: Ngwọta-ihe ngwọta maka nhazi ihe ịma aka (dịka ọmụmaatụ, ntụpọ epitaxial oyi akwa).

Ebumnuche anyị bụ guzobe 6-inch conductive monocrystalline SiC na polycrystalline SiC composite substrate dị ka ihe kacha mma na-arụ ọrụ ọnụ ahịa maka SiC ike eletrọnịkị, na-enye nkwado njedebe na njedebe site na prototyping na mmepụta olu.

Mmechi

SiC nke monocrystalline nke anụ ọhịa 6 na-arụ ọrụ na mkpụrụ osisi polycrystalline SiC na-enweta nguzozi nhụsianya n'etiti arụmọrụ yana ọnụ ahịa site na nhazi ngwakọ mono/polycrystalline ọhụrụ ya. Ka ụgbọ ala eletrik na-abawanye na ụlọ ọrụ 4.0 na-aga n'ihu, mkpụrụ a na-enye ntọala ihe a pụrụ ịdabere na ya maka eletriki eletrik na-esote ọgbọ. XKH na-anabata mmekorita iji nyochaa ikike teknụzụ SiC.